Sparking the Repair “Can-Do” Attitude: Enhancing Users’ Willingness to Repair through Design Support in Fault Diagnostics

Renske van den Berge *,1, Lise Magnier 1, and Ruth Mugge 1,2

1 Delft University of Technology, Delft, the Netherlands

2 University of Amsterdam, Amsterdam, the Netherlands

Current production and consumption patterns of consumer electronics have a negative impact on our environment. Designers can contribute to changing these patterns with more sustainable product design. Prolonging product lifetimes can have a positive impact, for which repair is a promising solution. However, the fact that a product can be physically repaired does not mean that users will act accordingly. Users generally have a low ability to repair consumer electronics. We suggest that design interventions may increase users’ can-do repair mentality, leading to a higher intention to repair. In three experiments, we tested the effect of a design intervention, namely the presence of a fault indication, on users’ willingness to repair. Our results showed a significantly higher willingness to repair in the presence of a fault indication, which is explained by a higher level of perceived self-efficacy (i.e., a can-do attitude). However, this result only holds true for products that are relatively less likely to be professionally repaired, such as coffee makers and (handstick cordless) vacuum cleaners, and not for washing machines, which are more likely to be professionally repaired. We end with practical design implications, limitations, and future research directions.

Keywords – Design for Repair, Product Lifetime Extension, Fault Indication, User Behavior, Circular Economy.

Relevance to Design Practice –This research explains how a fault indication can encourage users to repair products. This knowledge is relevant for design practitioners who aim to design long-lasting and circular (electronic) products.

Citation: Van den Berge, R., Magnier, L., & Mugge, R. (2023). Sparking the repair “can-co” attitude: Enhancing users’ willingness to repair through design support in fault diagnostics. International Journal of Design, 17(3), 25-39. https://doi.org/10.57698/v17i3.02

Received April 28, 2023; Accepted November 17, 2023; Published December 31, 2023.

Copyright: © 2023 Van den Berge, Magnier, & Mugge. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content is open-accessed and allowed to be shared and adapted in accordance with the Creative Commons Attribution 4.0 International (CC BY 4.0) License.

*Corresponding Author: r.b.r.vandenberge@tudelft.nl

Renske van den Berge is a Ph.D. candidate at the Faculty of Industrial Design Engineering at Delft University of Technology (TU Delft). After obtaining her M.Sc. in Strategic Product Design, she worked in industry before returning to TU Delft in 2019. Renske studies Sustainable Consumer Behavior in the context of a circular economy. Her main research interests are in the field of consumer adoption of circular consumption and practices. Specifically, she focuses on how design can stimulate product lifetime extension and repair practices among users. She has previously published her research in Current Opinion in Psychology and the Journal of Industrial Ecology.

Lise Magnier is an associate professor of Sustainable Consumer Behavior at the Faculty of Industrial Design Engineering at TU Delft. Lise’s research interests lie in the fields of circular and sufficient consumption. Specifically, she studies how design interventions can influence the adoption of circular and sufficient behaviors. She has published in journals such as Journal of Environmental Psychology, Food Quality and Preference, Resources, Conservation and Recycling, or Journal of Cleaner Production.

Ruth Mugge is a professor of Design for Sustainable Consumer Behavior at the Faculty of Industrial Design Engineering at TU Delft and a part-time professor of Responsible Marketing at the Amsterdam Business School at the University of Amsterdam. Her main research interests are (sustainable) consumer behavior, product longevity, design for behavior change, and design for the circular economy. She has received both European and national (NWO) funding for her research, among which a personal VICI grant on the value of design for slowing down premature obsolescence. She has published on these topics in various scientific journals, such as the International Journal of Design, Design Studies, Journal of Product Innovation Management, and Resources, Conservation and Recycling, in which Ruth also serves as an Associate Editor.

Introduction

The current approach to production and consumption has negative consequences for our environment. The growing production of electronic products severely impacts our environment due to CO2 climate emissions, leading to an increase in temperature and a rise in sea level (Allwood et al., 2011; Bakker et al., 2014). Additionally, such production requires the extraction of scarce (metal) materials. The sourcing, processing, and disposal of these materials are problematic, as they result in water and land pollution, thereby negatively impacting the global environment and health. Growth in the production of electronic products can also lead to material scarcity. Our dependence on critical materials used for (modern) technologies poses a potential societal risk (Heacock et al., 2016; Köhler, 2012). Despite these problems, prior studies have shown that the lifetimes of electronic products are becoming ever-shorter (Park, 2010). This results in a growing stream of e-waste, which is expected to continue to rise in future scenario studies (Parajuly et al., 2019).

Designers could possibly reverse these negative consequences of consumption via product, service, and system designs. The principles of the Circular Economy (CE) provide promising solutions to change the way we produce and consume products (Ellen MacArthur Foundation, 2013). Even though interest in CE is growing (Geissdoerfer et al., 2017), attention is still largely focused on product recycling (e.g., Kirchherr et al., 2017). Recycling is a less preferred option in a CE because the product integrity (i.e., initial value) is lost (Den Hollander et al., 2017). Retaining products’ initial value through prolonged usage should be favored instead, as this slows down the material and energy flows of production and consumption and reduces the impact on the environment (Bakker & Schuit, 2017; Konietzko et al., 2020; McCollough, 2009). However, in order to move from the traditional “take, make and dispose” mindset into a CE, users need to change how they interact with electronic products.

Prior research has indicated the potential of repair of (partially) malfunctioning products to prolong product lifetimes (Bocken et al., 2014; Magnier & Mugge, 2022). Yet, many products nowadays are not designed to be repaired (Proske et al., 2017; Rosborou, 2020; Wieser et al., 2015). Past research has proposed several ways to facilitate repair by design (Raihanian Mashhadi et al., 2016; Sabbaghi et al., 2016). These repair strategies generally take a design engineering perspective and address technical aspects of the product design (e.g., ease of disassembly). However, even if a product is technically repairable, it does not mean that users will act accordingly (Makov & Fitzpatrick, 2021). At present, users often do not consider repairing electronic products (Jaeger-Erben et al., 2021; Magnier & Mugge, 2022), and are more likely to replace them instead (Harmer et al., 2019; Hennies & Stamminger, 2016; Wieser & Tröger, 2018).

The decision to repair is affected by many factors. Low ability to repair is among the major hindrances preventing users from fixing their electronic products (Ackermann et al., 2018). Users often lack the knowledge and skills to execute repairs themselves and even if they do, the repair task can be time demanding. Furthermore, it may be difficult to find spare parts and their delivery conditions (e.g., price, delivery time) may be deficient (Jaeger-Erben et al., 2021; Rogers et al., 2021; Terzioğlu, 2021). When employing professional repair, the inconvenience of repair services is discouraging (e.g., availability, time-consuming; Poppe et al., 2021). While some studies suggested that environmental concerns can be a motivator for repair (Laitala et al., 2021; Sonego et al., 2022; Terzioğlu, 2021), the high costs of repair can make it perceived as a non-rational decision. Repair is often perceived as economically unattractive because the low prices of new products make replacement a more obvious choice (Brusselaers et al., 2019; Van den Berge et al., 2023a). However, research has shown that for both washing machines and vacuum cleaners, repair can be considered a more economically favorable option than replacement during most of their lifetime (Brusselaers et al., 2019; Svensson et al., 2022). Unfortunately, many users are not aware of this flawed assessment of the low perceived value of repair. One could argue that an increased ability to repair (i.e., competence) could also facilitate making better cost-benefit estimations, thereby overcoming repair cost barriers.

Despite the value of design as an important catalyst for encouraging users’ repair behavior (Sonego et al., 2022), past research has demonstrated a limited focus on the integration of the user perspective in the design (process) of circular offerings (Camacho-Otero et al., 2018). A potential barrier for repair that design should address is that users are often not aware of the causes of their electronic product failures (Pérez-Belis et al., 2017; Pozo Arcos et al., 2021). Not being able to diagnose the failure may negatively influence users’ estimated ability to repair because it reduces their level of perceived self-efficacy toward repair. Perceived self-efficacy is explained as a person’s can-do mentality: the belief in a personal capacity, or ability, to perform specific tasks (Fuchs et al., 2010). For designers, it is important to understand how design can increase users’ level of self-efficacy toward repair in order to positively affect their willingness to repair electronic products.

This paper aims to study if users’ willingness to repair electronic products can be increased via an intervention in product design. Specifically, we present three experiments in which we used a fault indication as a design intervention to increase users’ self-efficacy to repair. We tested whether this design intervention influenced the willingness to repair a malfunctioning product. We used an experimental set-up because this allowed us to empirically test the effect of including a fault indication on users’ willingness to repair while controlling for other influencing effects. After presenting our findings, we provide theoretical implications for future research. Also, we discuss practical implications for designers of electronic products that aim to stimulate repair via their (circular) product designs.

Willingness to Repair and Perceived Self-Efficacy

When aiming to stimulate users’ repair behavior via product design, it is important to consider user perspectives during the process of repairing. Repairing involves several steps: diagnosing the failure, disassembling the product, repairing the defective component, reassembling the product, and functional testing. The first step of failure diagnosis is crucial in the repair process (Pozo Arcos et al., 2020; Sabbaghi et al., 2017). In some cases, it may be perfectly clear what the failure is, such as when a smartphone’s screen is broken; the user can more easily determine whether the product can be repaired. A cost assessment can be made and as a result, the user can make a value trade-off on whether a repair would be worthwhile (Van den Berge et al., 2021). On the other hand, if a user is unable to accurately assess whether and how repair can restore the product value, this can be detrimental when determining whether it would be worthwhile to either replace or repair a malfunctioning product. A study by Pozo Arcos et al. (2021) showed that electronic product designs generally fail to provide fault diagnosis guidance to users. We propose that a fault indication can provide such guidance and will therefore encourage users to repair instead of replacing their products.

The Effect of a Fault Indication on the Willingness to Repair

A fault indication is a signal (e.g., a code on a display, or a colored/blinking light) appearing on the product when a failure occurs. The user can look up the meaning of the code or light in the product manual or online to learn the cause of the failure. Tecchio et al. (2016) suggested that in the case of washing machines and dishwashers, fault indications provide useful information that supports users in diagnosing a product failure. However, there is no empirical evidence as to whether such fault indications help to stimulate people’s willingness to repair. One could argue about whether providing knowledge about the product fault is always enough to stimulate repairs. Specifically, there are many situations in which the failure is obvious (e.g., a broken smartphone screen), but people are still unwilling to repair because of a variety of reasons (e.g., the hassle of collecting the right spare part, the time it takes to figure out the repair options, or the expected costs). Despite these barriers to conducting repair, we propose that a failure indication on the product itself will help users to overcome the first hurdle—diagnosis. This will make them feel more knowledgeable, increasing their willingness to repair. Accordingly, we hypothesize:

H1—Users will be more willing to repair electronic products when a fault indication is present, compared to when a fault indication is absent.

The Mediating Effect of Perceived Self-Efficacy

To successfully incorporate repair-stimulating interventions in product designs, it is important for designers to understand the underlying mechanism of how a fault indication increases the willingness to repair. According to the Theory of Planned Behavior, attitude, subjective norms, and perceived behavioral control influence the intention (i.e., willingness), and consequently, the specific targeted behavior of users (Azjen, 1991). The attitude and subjective norms refer to the individual’s personal beliefs and the normative beliefs of society toward performing a certain behavior. Perceived behavioral control refers to a person’s perception of the ease or difficulty of performing a specific targeted behavior. In the literature, perceived behavioral control is conceptually related to the perceived level of self-efficacy (i.e., personal capability) (Fuchs et al., 2010). The assessment of perceived self-efficacy or a person’s can-do mentality is based on a reflection of previous experiences and expected obstacles. The reported lack of repair skills (Jaeger-Erben et al., 2021; Rogers et al., 2021; Terzioğlu, 2021) demonstrates the low perceived self-efficacy that users usually have toward repair, which negatively influences their tendency to repair electronic products. Increasing users’ perceived self-efficacy to repair may therefore encourage individuals’ repair intentions.

Displaying a fault indication informs the user about the cause of the failure—this gives the user more knowledge and thus control over the situation. The repair steps can be more easily identified than when no such indication is displayed. We, therefore, expect that the users’ self-efficacy (and the related perceived behavioral control) toward the targeted repair behavior would increase. Subsequently, an increased level of self-efficacy would positively increase their willingness to repair, leading to the following hypothesis:

H2—The perceived level of self-efficacy will mediate the effect of a fault indication (absent or present) on the willingness to repair electronic products.

General Methodology

To empirically test if users’ willingness to repair electronic products can be increased via an intervention in product design, three studies using a scenario-based experimental approach were conducted. The experimental setup allowed us to isolate and test the specific effects of a chosen intervention (i.e., fault indication). Moreover, it enabled us to uncover mainstream effects (rather than unique, individual cases) of the intervention (Field & Hole, 2002).

Study Design and Stimuli

We tested the effect of the absence/presence of a fault indication on participants’ intentions to repair a broken product in four product categories. Specifically, in each study, we randomly presented the participants with a scenario of a broken product, which was either presenting no fault indication or a fault indication to the user. The scenarios consisted of a short text and a visual depiction of the product. To limit the influence of potential aesthetic preferences, all products had a prototypical appearance and color. The brand name and logo were removed to prevent personal preferences and prior associations from influencing the results. The text provided information about the model, performance (state), time of ownership, and the fact that the product failed. Specifically, the product was textually presented as a mid-range model that, before breaking down, had performed normally compared to similar products. Information about the performance was added to reduce the possibility that uncertainty about the satisfaction level of the initial state of the product would influence the results. Furthermore, the age of products can play an important role in the decision to repair, as product value tends to depreciate during its lifetime (Makov & Fitzpatrick, 2021; Van den Berge et al., 2021). To make sure a repair would still be considered a valuable option for the participant, we determined the time of ownership between the legal two-year warranty period (i.e., during which the manufacturer covers repair costs) and the average actual lifetime of the chosen product. We used product-specific common failures in our scenarios. All failures across the studies match in such a way that they prevented the products from performing their primary function. In this way, we ensured that the participants would not think that the device could still be used despite the failure, which may influence their repair decision. If the fault indication was present, the indication was visually added to the picture of the product together with an informative text about the specific failure. The scenarios can be found in Appendix.

Procedure and Measures

Participants were asked to empathize with the scenario and answer a series of questions as if this situation had occurred in their everyday lives. To collect the data, we used Qualtrics software to design an online survey. This survey included several measurements on multi-item scales. We measured participants’ willingness to repair the product using the following three items: “How likely/inclined/willing are you to have this product repaired?” (1 = not at all, 7 = very much; adapted from White et al., 2011). Participants’ level of self-efficacy was measured using the following three items: “I feel competent enough to select the best repair actions needed for this product,” “I feel that I have the relevant knowledge and expertise to make sound evaluations about the repair actions needed for this product,” and “I had difficulties evaluating the repair actions needed for this product” (reversed item: 1 = strongly disagree, 7 = strongly agree; adapted from Fuchs et al., 2010). Lastly, to check if our manipulation of the fault indication was successful, we asked participants about their understanding of the cause of the failure using the following three items: “The fault was clear to me,” “I would be able to identify the type of failure,” and “I have had enough information to know the type of failure” (1 = strongly disagree; 7 = strongly agree).

Data Collection and Analysis

Data was collected via Prolific, which is an online platform to recruit participants (www.prolific.co). To make sure participants could empathize with the possible repair need, the minimum age of the participants was set to 25 years. This minimum age would increase the likelihood that participants have personally owned the product for several years and could therefore imagine what they would do if it broke down. The collected data was analyzed using SPSS. In the analyses, we compared the means of the different conditions to test the effects of the fault indication on the willingness to repair and the mediation of the perceived self-efficacy. Unless suggested otherwise, the assumptions of normality and homogeneity were met in our analyses.

Study 1a

The purpose of this first study was to investigate whether the presence of a fault indication increases the willingness to repair consumer electronics (H1). We additionally investigated whether this can be explained by an increased level of self-efficacy (H2).

Method

Study Design and Stimuli

Study 1a consisted of a between-subject experimental design with two conditions (fault indication: absent vs. present). We chose to utilize a coffee maker as a target product for this study for several reasons. Coffee makers are widespread in households—drip filter machines are particularly common, with a relatively high use intensity (three times a week on average) and high ranking among appliances that most recently broke down (Pérez-Belis et al., 2017; Stanek et al., 2021). Also, the majority of these coffee makers are not considered for repair and many users find them not worth mending when they can get a new one for a similar price (Jaeger-Erben & Hipp, 2018; Pérez-Belis et al., 2017). Lastly, studies have shown that repairing coffee makers is more beneficial for the environment than replacing it (Bovea et al., 2020), and therefore we considered them as an appropriate product category for our study. As the average lifetime of a coffee maker is around six years (Pérez-Belis et al., 2017)) we included a time of ownership of three years in the scenarios.

For coffee makers, one of the most common failures is the calcification of the components (Postma et al., 2019), which mostly affects components subjected to (hot) water flows. For example, a rubber seal inside a coffee maker is susceptible to calcification. In the scenario without a fault indication (i.e., absent), a description of the failure with no indication of its cause was presented. The product failed and was not able to brew coffee anymore. In the scenario with a fault indication (i.e., present), an error code (fault 2) was displayed on the coffee maker; this code was explained in the (online) manual as meaning that the rubber seal of the water basin was damaged and needed to be replaced, cf. Appendix.

Measures and Sample

Participants evaluated the scenarios on multi-item scales measuring their willingness to repair (α = .95) and level of perceived self-efficacy. We excluded the third item of the self-efficacy scale as this negatively affected reliability (α < 0.70). A reason for the low Cronbach’s alpha could be that the third item had a reverse phrasing. As only two items were left, we checked the Pearson correlation coefficient to evaluate the reliability of the self-efficacy scale. This showed a strong positive correlation (r = .87). Lastly, the participants completed the manipulation check (α = .91). In total, 104 participants completed the survey, of whom 33 indicated that they do not use a coffee maker that runs on electricity (i.e., that needs a power plug to function) at home. We assumed they would have found it more difficult to relate to the described situation and thus were excluded from the dataset. Also, two participants who failed the attention check were excluded. This resulted in a total of 69 participants (Age: M = 35.87, SD = 10.86; Gender: Male = 44.9%, Female = 55.1%).

Results

Manipulation Check

We first performed an independent sample t-test to check if our manipulation was successful. We used the fault indication as the independent variable (IV) and the participant’s understanding of the cause of the failure as the dependent variable (DV). The results showed a significant difference in participants’ understanding of the failure when the fault indication was present (Mabsent = 3.24 vs. Mpresent = 5.29; t(67) = -5.12; p < .001). Participants thus better understood the cause of the failure when the fault indication was shown, and our manipulation was successful.

The Effect of a Fault Indication on the Willingness to Repair

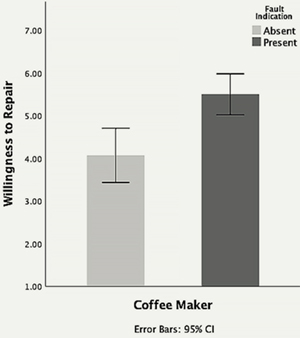

We conducted bootstrapped (5,000 samples) parametric tests because the willingness to repair data deviated from the normal distribution. These tests are fairly robust against violations of the normal distribution assumption (e.g., Barber & Thompson, 2000; Blanca et al., 2017). We performed an independent sample t-test with fault indication (IV) and willingness to repair (DV). Our results showed that when the fault indication was present, the willingness to repair the coffee maker was significantly higher compared to when the fault indication was absent (Mabsent = 4.06 vs. Mpresent = 5.49; t(67) = -3.60; p < .001, 95%CI [-2.29,-.68]), see Figure 1. These findings confirm H1.

Figure 1. The willingness to repair a CM with or without fault indication.

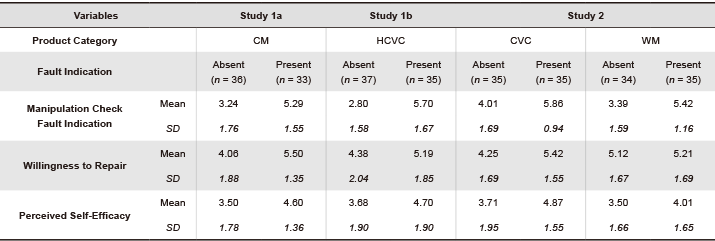

The Mediating Effect of Self-Efficacy

To test if the positive effect of a fault indication on the willingness to repair a coffee maker could be explained by a higher level of perceived level of self-efficacy, we conducted a mediation analysis. First, we performed an independent sample t-test to analyze the effect of the presence of a fault indication (IV) on the level of self-efficacy (DV). The results showed that participants in the present condition had a significantly higher level of perceived self-efficacy (Mabsent = 3.50 vs. Mpresent = 4.61; t(67) = -2.88, p < .01, 95% CI [-1.84, -.34]), cf. Table 1.

To uncover whether the increased level of self-efficacy could explain the increased willingness to repair, we performed a mediation analysis using model 4 of the PROCESS macro for SPSS (Hayes, 2013). The indirect effect of the fault indication on the willingness to repair for the level of self-efficacy was tested using non-parametric bootstrapping and showed significant results (b = 0.53; BootSE = .24; 95% CI [.13, 1.07]). The direct effects revealed that the fault indication positively influenced the level of self-efficacy (b = 1.01; SE = .38; 95% CI [.34, 1.87]; p <.01)) while self-efficacy, in turn, positively influenced the willingness to repair (b = .48; SE = .11; 95% CI [.25, .70]; p < .001). As both direct and indirect effects are significant, these results show a partial mediation confirming H2.

Study 1b

The purpose of Study 1b is to generalize the findings of Study 1a by checking whether the positive effect of the fault indication on the willingness to repair remains stable for different types of products. Additionally, considering that the failure selected in Study 1a is a specific error in coffee makers, it may be useful to validate our outcomes with other types of defects. Reflecting on the stimuli used in Study 1a, repairing the rubber seal of the water reservoir of a coffee maker could have been perceived as a task with relatively low estimated repair costs. It is thus worthwhile to replicate the study with a repair need scenario that involves spare parts requiring a higher investment and check if the results remain stable. Therefore, we empirically tested H1 and H2 for the scenario of a broken handstick cordless vacuum cleaner.

Method

Study Design and Stimuli

The study consists of a between-subject experimental design with two conditions (fault indication: absent vs. present). We chose to utilize a handstick cordless vacuum cleaner, because vacuum cleaners in general are commonly owned household devices, but often for this specific type battery fails early in the product’s lifetime (Thysen & Berwald, 2021). Additionally, the replacement of a failing battery is expected to be perceived as a higher investment than the replacement of the damaged coffee maker rubber seal used in Study 1a. In line with Study 1a, the product was introduced as being a mid-range model with normal performance. The time of ownership was estimated to be three years. In the scenario without the fault indication, it was textually indicated that the product failed and did not function anymore. In the condition with the fault indication present, a red light on the battery was added and the scenario text referred to the (online) manual indicating that this meant that the battery was damaged and needed to be replaced, cf. Appendix.

Measures and Sample

Similar as Study 1a, the participants evaluated the scenarios on multi-item scales measuring their willingness to repair (α = .96) and level of perceived self-efficacy (using only the first two items; r = .77) and completed the manipulation check (α = .96). Five participants who failed the attention check were excluded from the dataset. Of all participants, 55.6% indicated owning a handstick cordless vacuum cleaner. However, most of the households in the EU own a vacuum cleaner (penetration rate of 1.3), but handstick cordless vacuum cleaners are less commonly owned than cylindric vacuum cleaners (Rames et al., 2019). As both are similar in terms of functionality, we decided to also include the participants who indicated they do not own an HCVC. The final sample consisted of 72 respondents (Age: Mean = 38.11, SD = 8.69; Gender: Male = 47.2%, Female = 52.8%).

Results

Manipulation Check

We first performed an independent sample t-test to check if our manipulation was successful. The results showed a significantly higher understanding of the cause of the fault when the fault indication was present (Mabsent = 2.80 vs. Mpresent = 5.70; t(70) = -7.57; p < .001, 95% CI [-3.67, -2.14]), indicating that our manipulation was successful.

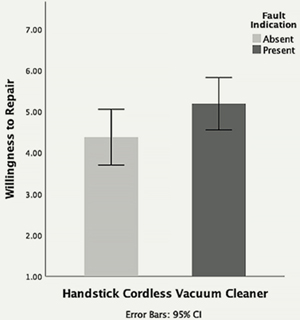

The Effect of a Fault Indication on the Willingness to Repair

We performed an independent sample t-test using bootstrapping with fault indication (IV) and the willingness to repair (DV). Our analysis showed a marginally significant effect of fault indication. Even though only marginally significant, the means are in the expected direction, suggesting that participants were more willing to repair the product when the fault indication was present (Mabsent = 4.38 vs. Mpresent = 5.19; t(70) = -1.77; p < .10, 95% CI [-1.71, -.11]), which provides further support for H1, Figure 2.

Figure 2. The willingness to repair a HCVC with or without fault indication.

The Mediating Effect of Self-Efficacy

An independent sample t-test with the fault indication (IV) and self-efficacy (DV) showed that a fault indication significantly increased participants’ self-efficacy (Mabsent = 3.68 vs. Mpresent = 4.70; t(70) = -2,28, p < .05, 95% CI [-1.90, .15]), cf. Table 1. Next, a mediation analysis (using PROCESS macro for SPSS model 4 (Hayes, 2013)) revealed a significant indirect effect of self-efficacy mediating the relationship between the fault indication and the willingness to repair (b = 0.57; SE = 0.28; 95% CI [.07, 1.18]). The fault indication positively influenced the level of self-efficacy (b = 1.02; SE = .45; 95% CI [.13, 1.92]); p <0.05), and self-efficacy positively influenced the willingness to repair (b = .56; SE = .10; CI [.35, .76]; p < .001), providing support for H2.

Discussion of Study 1a and 1b

The results of Study 1a and 1b show that understanding the cause of a product failure by implementing a fault indication in the design of electronic products may trigger users to proceed to repair. Both studies demonstrated that a fault indication positively influenced the willingness to repair, which was explained by an increased level of self-efficacy. When provided with a fault indication, participants perceived an increased level of self-efficacy and thus felt more competent and knowledgeable to make sound evaluations about repair actions when a fault indication was provided. This enabled participants to better estimate the time and costs of the repair, for example. The marginally significant results of Study 1b of the fault indication on the willingness to repair could be due to the relatively small sample size.

Reflecting on the used stimuli in our Studies 1a and 1b, it is worthwhile to investigate whether an increased level of self-efficacy is also helpful for electronic products that users are more likely to have professionally repaired. For example, for (high investment) products with higher technological complexity, users are used to contacting professional repair technicians to fix possible defects. For these types of products, a fault indication and the subsequent increase in self-efficacy may thus have a limited effect because users do not need to feel competent, as the repair is performed by a professional.

The Moderating Effect of Likelihood of Professional Repair

The effect of a fault indication on people’s willingness to repair may depend on differences in the likelihood of professional repair, which is dependent on the type of product. Especially for low-investment products, buying a new one can be perceived as a low-risk and convenient choice compared to finding out what is wrong with the product and consequently pursuing repair. For example, products that are relatively low in investment or less technologically complex, such as CM and HCVC, are less likely to be considered for professional repair compared to a more technologically complex (high-investment) product such as a washing machine (Rogers et al., 2021). That said, a fault indication can lower the repair barrier, because the user is informed about the cause of the failure and can make a better judgment about whether repair, for example, would turn out to be easy to perform or a more economically attractive option. However, more technical products representing a higher investment, such as a dishwasher or washing machine, may be more likely to be repaired by a professional (Sabbaghi et al., 2016). Specifically, the investment price of the product is high enough to consider a repair worthwhile or its technological complexity goes beyond users’ repair knowledge. For these products, we expect that a fault indication is less likely to influence users’ willingness to repair because there is less need for the user to know the cause of the failure as a professional is consulted in any case. We, therefore, hypothesize the following:

H3—The fact that a product is likely to be repaired professionally moderates the effect of a fault indication on the willingness to repair electronic products. Specifically, the presence of a fault indication positively affects the willingness to repair if the product is unlikely to be professionally repaired. If the product is likely to be professionally repaired, the effect of a fault indication is not significant.

Study 2

The purpose of Study 2 is to generalize the findings of Studies 1a and 1b and uncover if the likelihood of performing professional repair will serve as a moderator for the effect of the fault indication on users’ willingness to repair products (H3).

Method

Study Design and Stimuli

The study consisted of a 2 (fault indication: absent vs. present) × ٢ (product category: high vs. low likelihood of professional repair) between-subject experimental design. We chose a cylindric vacuum cleaner as a product category with a relatively low likelihood of being professionally repaired. A cylindric vacuum cleaner is similar in terms of functionality to the handstick cordless vacuum cleaner of Study ١b, as well as comparable in terms of the complexity of its technological operation. Also, for the majority of the failure scenarios for a vacuum cleaner, repair and reuse are most beneficial for the environment (Bovea et al., 2020). The penetration rate of 1.3 vacuum cleaners per household in the EU (Rames et al., 2019) shows their wide dissemination. However, a study in the UK showed that only 18% of the participants have had their currently-in-use vacuum cleaner repaired (Harmer et al., 2019). We chose a washing machine for a product category with a higher likelihood of being professionally repaired. Washing machines are also common household products but represent a relatively expensive investment and can be considered technologically more complex than vacuum cleaners. Also, earlier studies have shown that users consider themselves to have low repair competence for washing machines (Jaeger-Erben et al., 2021), and are likely to consider turning to a professional to repair them ((Jaeger-Erben et al., 2021; Magnier & Mugge, 2022).

Each participant was presented with one of the four conditions. The average lifetime of a cylindric vacuum cleaner is estimated at around 6.0 years and a washing machine is around 8.3 years (Wieser et al., 2015). Therefore, we determined the time of ownership of four years for a cylindric vacuum cleaner and six years for a washing machine as a moment in which the user would still consider repair to be a worthwhile option but may also be likely to consider replacing their product. We chose a damaged filter as a failure of the cylindric vacuum cleaner, as earlier studies showed that a common symptom of failure is not having suction. Many users do not maintain their filters, which results in failures, as preventing a blocked filter is essential for keeping a vacuum cleaner in good working condition (Harmer et al., 2019; Pozo Arcos et al., 2020). In the case of washing machines, we chose damaged drum bearings because this failure type is one of the most common breakdowns reported by both users and professional repairers (Tecchio et al., 2019; Thysen & Berwald, 2021). In the scenarios where a fault indication was absent, the cylindric vacuum cleaner lost its suction power and the washing machine was not able to activate the wash programs anymore. In the scenarios in which the fault indication was present, a red light lit up next to a filter icon on the cylindric vacuum cleaner, and an error code (fault 5) was shown on the washing machine’s display. Both fault indications referred to the (online) manual, which provided details about the failure and indicated which component needed to be replaced, cf. Appendix.

Measures and Sample

Following the procedure of Studies 1a and b, we measured participants’ willingness to repair the product (α = 0.95), their level of perceived self-efficacy (using only the first two items, r = 0.76), and completed the manipulation check (α = 0.88). Additionally, we asked participants to rate the following item: “How likely are you to have this product repaired by a professional repairer?” (1 = not at all; 7 = very much). Participants who did not own the product (WM: n = 4; CVC: n = 3) and who failed the attention check (n = 2) were excluded from the dataset. This resulted in a total of 139 participants (Age: M = 41.10, SD = 10.61; Gender: Male = 54.0%, Female = 46.0%).

Results

Manipulation Check

To check our manipulation of the fault indication, we performed two independent sample t-tests for the CVC and WM separately. Results showed that there were significant effects of the presence of a fault indication on the understanding of the cause of the failure for the cylindric vacuum cleaner (MCVC absent = 4.02 vs. MCVC present = 5.86; t(68) = -5.63; p < .001, 95% CI [-2.48, -1.19]) and the WM (MWM absent = 3.39 vs. MWM present = 5.42; t(67) = -6.05; p < .001, 95% CI [-2.67, -1.37]). Additionally, we performed an independent samples t-test with the product category as the independent variable and the likelihood of professional repair as the dependent variable to check if our manipulation on the likelihood of being professionally repaired was successful. The results revealed that cylindric vacuum cleaners were significantly less likely to be professionally repaired compared to washing machines (MCVC = 3.86 vs. MWM = 5.72, t(137) = 5.53; p < .001, 95% CI [1.20, 2.50]). All manipulations were thus successful.

The Effect of a Fault Indication on the Willingness to Repair

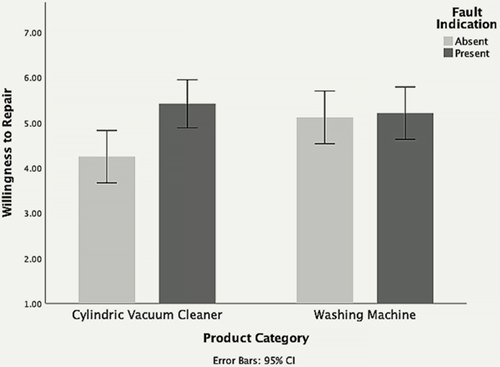

We performed a two-way bootstrapped ANOVA using the fault indication and product category as independent variables and willingness to repair as the dependent variable. Participants were significantly more willing to repair a product when a fault indication was present (Mabsent = 4.68 vs. Mpresent = 5.31; F(1,135) = 5.09; p < .05, 95% CI [-1.19, -.08]), which supports H1. There was no significant main effect of the product category on willingness to repair. As hypothesized, there was a marginally significant interaction effect of the fault indication and product category on the willingness to repair [F(1,135) = 3.72; p = .056], cf. Figure 3.

Figure 3. The willingness to repair a CVC and WM with or without fault indication.

Next, we analyzed the effects per product category. Our bootstrapped independent sample t-tests results showed that for the cylindric vacuum cleaner, the willingness to repair was significantly higher when the fault indication was present (MCVC absent = 4.25 vs. MCVC present = 5.42, t(68) = -3.03; p < .01, 95% CI [-1.94, -.40]), providing further support for H1. However, for the washing machine, no significant difference between the two conditions was found (MWM absent = 5.12 vs. MWM present = 5.21, t(67) = .05; p > .50, 95% CI [-.89, .69]), cf. Table 1.

The Moderated Mediation Effect of Self-Efficacy

We first performed a bootstrapped two-way ANOVA using the fault indication and product category as the independent variables, and the level of self-efficacy as the dependent variable. The results showed a significantly higher level of self-efficacy when the fault indication was present (Mabsent = 3.61 vs. Mpresent = 4.44; F(1,135) = 8.35, p < .01). Also, a marginally significant effect was found for product category, suggesting that participants had lower perceived self-efficacy for the WM compared to the cylindric vacuum cleaner (MWM = 3.75 vs. MCVC = 4.29; F(1,135) = 3.43, p < .10). There was no significant interaction effect.

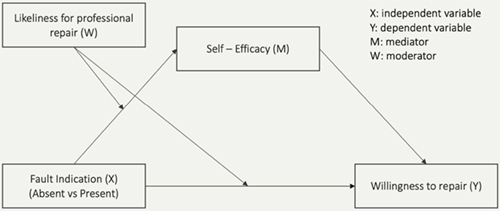

For the moderated mediation analysis, we used model 8 of the PROCESS macro for SPSS including bootstrapping (Hayes, 2013), see Figure 4. We included the fault indication as the independent variable, willingness to repair as the dependent, self-efficacy as the mediator, and the likelihood of professional repair as a moderator. The indirect effect of the fault indication on the willingness to repair showed a statistically significant index of moderated mediation (b = -.10; BootSE = .05; 95% CI [-.20, -.01]). This means that the indirect effect of fault indication on the willingness to repair through self-efficacy was stronger for the participants who were less likely to professionally repair. These results confirm H3.

Figure 4. Moderated Mediation based on Hayes (2013) Model 8.

Table 1. The means and standard deviations (SD) of the variables for the study conditions.

General Discussion

Our society faces environmental challenges that call for the urgent development of more circular and sustainable products. We provided empirical evidence that design for repair can be a fruitful avenue to further pursue sustainability-focused design research. Across three studies we showed that a fault indication positively influences the willingness to repair electronic products. This effect was explained by an increased level of self-efficacy and was visible for a variety of failure types. Simply knowing what is wrong when products fail can thus empower users to take action and replace broken components. We must note that the willingness to repair electronic products that are likely to be professionally repaired (e.g., because they are complex or expensive to replace) was already high without providing a failure indication. For this reason, the lack of a significant effect of the fault indication on users’ willingness to repair these products is not considered an issue because these products are repaired relatively often anyway. In sum, we can conclude that a fault indication is generally an effective method to increase users’ willingness to repair failures for many consumer electronics.

The potential role of product design in facilitating users’ repair behavior has been highlighted in the past (Bocken et al., 2014; Magnier & Mugge, 2022). However, empirical research merely addressed the technical (design engineering) aspects of repairable designs (Raihanian Mashhadi et al., 2016; Sabbaghi et al., 2016; Sonego et al., 2022) while making objects physically repairable does not guarantee that the user will carry out repair actions (Jaeger-Erben et al., 2021; Makov & Fitzpatrick, 2021). By taking a user perspective, we go beyond the technical aspects of repairable designs and show that an increased perceived self-efficacy raises the likelihood that users will actually pursue repair actions. Even though our results may seem somewhat intuitive, the fact is that in today’s market, fault indications to aid consumers with repair are not often included in many electronic products. Furthermore, scientific research on the effects of fault indications has been lacking. Our results contribute to the literature on design for repair by demonstrating that fault indications can be of great relevance to stimulate repair, especially for low-investment products. Design practitioners can use our findings to explain the value of fault indications to other stakeholders in the design process, and thereby verify the need of potential additional investments. This is of great relevance for design practitioners aiming to extend product lifetimes via repair.

In the decision to replace or repair, users are often unable to accurately estimate whether or not a repair would be worthwhile (Van den Berge et al., 2023a), which may result in a negative attitude toward repair. Following the principles of the Theory of Planned Behavior, we showed that providing users with a fault indication increased their level of perceived behavioral control (or self-efficacy) and consequently their repair intentions. Furthermore, next to the effect on repair intent, perceived behavioral control may also positively affect the existing (individual) attitude toward repair (Azjen, 1991). In other words, users may develop a repair can-do attitude that will affect their individual beliefs about repair, which can consequently lead to a shift in subjective norms and beliefs. To ultimtely change the subjective norms of society, a critical mass of people willing to repair electronic household products is needed (Sunstein, 2019). Ultimately, increasing users’ can-do attitude can thus potentially be a useful step in a collective behavioral change toward a more sustainable society.

Practical Implications

Understanding how users’ repair behavior can be stimulated via product design is important for design practitioners who aim to contribute to a more circular society. Specifically, next to designing products that are physically repairable, designers should provide users with support in diagnosing the reasons for product failure. At present, fault (i.e., error) indications are available for specific household devices, such as washing machines and dishwashers (Tecchio et al., 2016). However, our results indicate that fault indications on coffee makers and vacuum cleaners, for which these are less often provided, would have the largest impact. Therefore, we suggest that designers should also consider incorporating fault indications in lower-investment and less complex products.

To manage the costs associated with implementing fault indications in the design, designers could focus on providing these only for the most commonly occurring failure(s). For most products, it is well-known what the most commonly occurring failures are. We suggest designers can implement appropriate sensors and fault indications accordingly. To avoid unnecessary failures, the fault indication should not complicate the functionality of the product. In addition, it should be clearly noticeable on the product, to ensure the user would not overlook it. Furthermore, the fault indication should be designed in a way that it feels approachable and helpful to users, thereby reducing the perceived complexity and anxiety of the repair task. For example, a coffee maker could signal a calcification (Postma et al., 2019), or a vacuum cleaner could signal the necessity of a filter replacement (Harmer et al., 2019) via the appearance of a (coloured) indicatory icon on the product’s display. Blinking lights may also be used as these attract much attention. However, with the design of such lights, designers should consider the speed of blinking, as a high tempo may induce anxiety, rather than prevent it. In addition, the fault indication should be easily traceable via an online manual or on the company website. Step-by-step guidance and/or movies explaining repair procedures could also be provided to further support the user’s ability to repair the product. Also, the aesthetic qualities of fault indicators should be considered because more attractive fault indications may be perceived as high-quality (what is beautiful is good principle; Dion et al., 1972), as well as more pleasurable (Desmet, 2012), thereby increasing the chances that users will take action. Fault indications can be made more attractive by implementing well-known design principles, such as harmony or unity and by integrating these indications seamlessly in the product design.

The fact that the willingness to repair a washing machine was quite high without a fault indication is promising because it means that users were already more prone to repair these products. For these products, it is important to design professional repair services that will not demotivate users in their steps towards professional repair. Fortunately, legislation that aims to make repair services more accessible and feasible (e.g., the Right to Repair) is currently under development. The consumer products market will need to adapt to comply with these regulations. In this respect, we suggest two potential directions to further increase the willingness to repair products via professional repair. For users who prefer a prompt solution for a malfunctioning product, a well-designed repair service that is market competitive with existing replacement services in terms of speed would be an interesting direction. For users who would like to save costs by repairing these products themselves, designers could consider exploring whether providing support beyond a fault indication would make users inclined to repair these more expensive and complex products. For example, support throughout the different repair steps via cues or an extended online repair support service, with (video) tutorials.

In addition, when designing for repair, we would also like to highlight the importance of the general physical interaction with the product to its perceived repairability. For example, a material that is easily scratched or damaged during repair, or sharp edges on product components that can hurt you could refrain users to pursuing repair actions. Also, too heavy or solid devices could be potentially intimidating for repair (Mugge et al., 2018). Furthermore, when implementing design interventions to increase users’ level of self-efficacy, designers should also consider the total environmental impact of the intervention. It is for example undesirable that the addition of a fault diagnosis will increase the complexity of the design, leading to earlier product failures, or will require many additional scarce resources that increase the overall footprint of the product. Designers should thus consider possible rebound effects of their interventions by performing life cycle analyses (LCA).

Past research has proposed product attachment as a different design strategy to extend product lifetimes (Mugge et al., 2005; Schifferstein & Zwartkruis-Pelgrim, 2008). If a person feels attached to an object, they are more likely to repair it when it breaks down because replacing it, would mean that the special meaning is lost. For these objects, fault indications are probably less needed as people will do their utmost best to try and repair such favorite objects. However, most electronic products are not likely to be objects of attachment, as coffee makers or vacuum cleaners are usually not emotionally laden objects and do not provide an irreplaceable special meaning (Mugge et al., 2008).

Lastly, encouraging repair behavior may be challenging because it is not in line with current linear business models. Designers may face challenges in making such products financially attractive for companies. Nonetheless, it is important to note that in a company’s contribution to a circular economy, the repair of products can have many positive impacts and is, therefore, worthwhile to consider. For example, well-designed repair services may create company revenue. This can be done directly by designing profitable repair services, and indirectly by creating brand loyalty. Using design for repair strategies may thus be helpful to create a competitive advantage in the highly competitive market of consumer electronics.

Limitations and Future Research Directions

Several limitations that provide interesting avenues for future research should be highlighted. First, our findings are limited to the effect of fault indications on users’ willingness to repair. The effect of fault indications on the service performance of repair professionals remains unexplored. Already knowing the cause of the failure makes the diagnosis step superfluous, thereby potentially decreasing time and costs involved in failure diagnostics. For example, a fault indication allows the repairer to order the appropriate spare parts beforehand and have them ready at the moment of repair. This may lead to a more efficient and less costly repair process, which will positively influence users’ repair decision-making. To substantiate this potential, we suggest future research to further investigate the effect of fault indications on the service performance of repair professionals.

Although our research focused on the failure diagnostics stage, we acknowledge that interventions at other stages in the repair process could also boost users’ level of repair self-efficacy. For example, design interventions that support the dis- or reassembly stages (e.g., screws or a notch indicating where a device can be opened, or icons on components indicating their function) may have a similar effect on self-efficacy but at other stages of the repair process. We recommend designing products in such a way that the “can-do” attitude is supported throughout the entire repair process. Furthermore, there may be more design interventions that could increase consumers’ repair can-do mentality. Therefore, studying other design interventions may also be helpful for product lifetime extension. Studies on how modular designs could increase the likeliness for do-it-yourself (DIY) repair have already shown promising results (Van den Berge et al., 2023b). To further expand on how design can stimulate repair intentions, we encourage design researchers to investigate the effects of such alternative design interventions on willingness to repair.

Providing a fault indication merely addresses the barrier of a problematic failure diagnosis. Whether a fault indication would also support overcoming other ability-related barriers such as high estimated repair costs or spare part availability (Laitala et al., 2021; Van den Berge et al., 2023a) remains unclear. We believe that providing fault indications could also be an opportunity to connect users to more specific repair information about spare parts, repair steps, and repair services (e.g., by referring to an (online) repair manual for support). This may consequently reduce the time and effort needed to collect information about the repair but may also remove incorrect assumptions about the repair (e.g., high costs for spare parts), thereby increasing willingness to repair. Therefore, it seems worthwhile to further explore the potential opportunities of implementing fault indications beyond the fact that they support failure diagnostics, taking away other repair barriers as well. Furthermore, while our focus was on how fault indications can improve repair self-efficacy, it is important to mention that the decision to repair is a complex process influenced by many more factors, such as the time needed for repair, cost-effectiveness, and understanding of the environmental benefits. We suggest future research should investigate how specific (design) interventions can influence these factors.

Furthermore, it is important to mention that the results reflect the intended behavior of our participants. The study was conducted in an experimental and controlled setting, due to which we measured participants’ intentions to repair their product in a scenario rather than their actual repair behaviors. Even though it is promising to see that people’s repair intentions increased as a result of the fault indication, we also realize that in a real-life setting, other factors may intervene due to which these intentions to repair may not necessarily result in actual repair behavior (a.k.a intention-behavior gap; Sheeran & Webb, 2016). Therefore, we would encourage future research to study the effects of a fault indication in a real-life setting.

Finally, self-efficacy may have a similar desirable effect on people’s willingness to repair other types of products, such as furniture or clothing, as many people do not execute repair because they lack the ability (Laitala et al., 2021). Fault indications such as error codes or blinking lights may not be appropriate for these types of products. Nevertheless, to contribute to a more circular society, we encourage designers and design researchers to explore possibilities to further increase users’ repair can-do mentality in the various repair stages and for different consumer products.

Conclusion

To stimulate people’s intentions to repair their consumer electronics, designers should consider increasing consumers’ repair can-do attitude. This can be achieved by providing design indications (e.g., a fault indication) that increase consumers’ perceived self-efficacy to repair. Especially for lower-investment electronic products, the results are relevant because many consumers do not consider it to be worthwhile to take these products for professional repair. Simply understanding a product’s failure can thus support consumer’s repair intentions, which is valuable knowledge for designers and design researchers that aim to extend the lifetimes of electronic products via repair.

Acknowledgments

This research was part of the PROMPT (Premature Obsolescense Multi-stakeholder Testing program) and has received funding from the European Union’s Horizon 2020 Research and Innovation program under grant agreement no. 820331.

References

- Ackermann, L., Mugge, R., & Schoormans, J. (2018). Consumers’ perspective on product care: An exploratory study of motivators, ability factors, and triggers. Journal of Cleaner Production, 183, 380-391. https://doi.org/10.1016/j.jclepro.2018.02.099

- Allwood, J. M., Ashby, M. F., Gutowski, T. G., & Worrell, E. (2011). Material efficiency: A white paper. Resources, Conservation and Recycling, 55(3), 362-381. https://doi.org/10.1016/j.resconrec.2010.11.002

- Azjen, I. (1991). The theory of planned behavior. Organizational Behavior and Human Decision Processes, 50(2), 179-211. https://doi.org/10.1016/0749-5978(91)90020-T

- Bakker, C., Wang, F., Huisman, J., & Den Hollander, M. (2014). Products that go round: Exploring product life extension through design. Journal of Cleaner Production, 69, 10-16. https://doi.org/10.1016/j.jclepro.2014.01.028

- Bakker, C. A., & Schuit, C. S. C. (2017). The long view: Exploring product lifetime extension. United Nations Environment Programme. https://wedocs.unep.org/20.500.11822/22394

- Barber, J. A., & Thompson, S. G. (2000). Analysis of cost data in randomized trials: An application of the non-parametric bootstrap. Statistics in Medicine, 19(23), 3219-3236. https://doi.org/10.1002/1097-0258(20001215)19:23<3219::AID-SIM623>3.0.CO;2-P

- Blanca, M. J., Alarcón, R., Arnau, J., Bono, R., & Bendayan, R. (2017). Non-normal data: Is ANOVA still a valid option? Psicothema, 29(4), 552-557. https://doi.org/10.7334/psicothema2016.383

- Bocken, N. M. P., Short, S. W., Rana, P., & Evans, S. (2014). A literature and practice review to develop sustainable business model archetypes. Journal of Cleaner Production, 65, 42-56. https://doi.org/10.1016/j.jclepro.2013.11.039

- Bovea, M. D., Ibáñez-Forés, V., & Pérez-Belis, V. (2020). Repair vs. replacement: Selection of the best end-of-life scenario for small household electric and electronic equipment based on life cycle assessment. Journal of Environmental Management, 254, Article 109679. https://doi.org/10.1016/j.jenvman.2019.109679

- Brusselaers, J., Bracquene, E., Peeters, J., & Dams, Y. (2019). Economic consequences of consumer repair strategies for electrical household devices. Journal of Enterprise Information Management, 33(4), 747-767. https://doi.org/10.1108/JEIM-12-2018-0283

- Camacho-Otero, J., Boks, C., & Pettersen, I. N. (2018). Consumption in the circular economy: A literature review. Sustainability (Switzerland), 10(8), Article 2758. https://doi.org/10.3390/su10082758

- Den Hollander, M. C., Bakker, C. A., & Hultink, E. J. (2017). Product design in a circular economy: Development of a typology of key concepts and terms. Journal of Industrial Ecology, 21(3), 517-525. https://doi.org/10.1111/jiec.12610

- Desmet, P. (2012). Faces of product pleasure: 25 positive emotions in human-product interactions. International Journal of Design, 6(2), 1-29.

- Dion, K., Bersheid, E., & Walster, E. (1972). What is beautiful is good. Journal of Personality and Social Psychology, 24(3), 285-290. https://doi.org/10.1037/h0033731

- Ellen MacArthur Foundation. (2013). Towards the circular economy: Economic and business rationale for an accelerated transition. https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf

- Field, A., & Hole, G. (2002). How to design and report experiments. SAGE.

- Fuchs, C., Prandelli, E., & Schreier, M. (2010). The psychological effects of empowerment strategies on consumers’ product demand. Journal of Marketing, 74(1), 65-79. https://doi.org/10.1509/jmkg.74.1.65

- Geissdoerfer, M., Savaget, P., Bocken, N. M. P., & Hultink, E. J. (2017). The circular economy–A new sustainability paradigm? Journal of Cleaner Production, 143, 757-768. https://doi.org/10.1016/j.jclepro.2016.12.048

- Harmer, L., Cooper, T., Fisher, T., Salvia, G., & Barr, C. (2019). Design, dirt and disposal: Influences on the maintenance of vacuum cleaners. Journal of Cleaner Production, 228, 1176-1186. https://doi.org/10.1016/j.jclepro.2019.04.101

- Hayes, A. F. (2013). Introduction to mediation, moderation and conditional process analysis. Guilford Press.

- Heacock, M., Kelly, C. B., Asante, K. A., Birnbaum, L. S., Bergman, Å. L., Bruné, M. N., Buka, I., Carpenter, D. O., Chen, A., Huo, X., Kamel, M., Landrigan, P. J., Magalini, F., Diaz-Barriga, F., Neira, M., Omar, M., Pascale, A., Ruchirawat, M., Sly, L., … Suk, W. A. (2016). E-waste and harm to vulnerable populations: A growing global problem. Environmental Health Perspectives, 124(5), 550-555. https://doi.org/10.1289/ehp.1509699

- Hennies, L., & Stamminger, R. (2016). An empirical survey on the obsolescence of appliances in German households. Resources, Conservation and Recycling, 112, 73-82. https://doi.org/10.1016/j.resconrec.2016.04.013

- Jaeger-Erben, M., Frick, V., & Hipp, T. (2021). Why do users (not) repair their devices? A study of the predictors of repair practices. Journal of Cleaner Production, 286, Article 125382. https://doi.org/10.1016/j.jclepro.2020.125382

- Jaeger-Erben, M., & Hipp, T. (2018). All the rage or take it easy–Expectations and experiences in the context of longevity in electronic devices. Descriptive analysis of a representative online survey in Germany. https://challengeobsolescence.info/wp-content/uploads/2018/03/Research-Group-OHA_Description-Online-Survey_2018.pdf

- Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling, 127, 221-232. https://doi.org/10.1016/j.resconrec.2017.09.005

- Köhler, A. R. (2012). Material scarcity: A reason for responsibility in technology development and product design. Science and Engineering Ethics, 19(3), 1165-1179. https://doi.org/10.1007/s11948-012-9401-8

- Konietzko, J., Bocken, N., & Hultink, E. J. (2020). Circular ecosystem innovation: An initial set of principles. Journal of Cleaner Production, 253, Article 119942. https://doi.org/10.1016/j.jclepro.2019.119942s

- Laitala, K., Klepp, I. G., Haugrønning, V., Throne-Holst, H., & Strandbakken, P. (2021). Increasing repair of household appliances, mobile phones and clothing: Experiences from consumers and the repair industry. Journal of Cleaner Production, 282, Article 125349. https://doi.org/10.1016/j.jclepro.2020.125349

- Magnier, L., & Mugge, R. (2022). Replaced too soon ? An exploration of Western European consumers’ replacement of electronic products. Resources, Conservation & Recycling, 185, Article 106448. https://doi.org/10.1016/j.resconrec.2022.106448

- Makov, T., & Fitzpatrick, C. (2021). Is repairability enough? Big data insights into smartphone obsolescence and consumer interest in repair. Journal of Cleaner Production, 313, Article 127561. https://doi.org/10.1016/j.jclepro.2021.127561

- McCollough, J. (2009). Factors impacting the demand for repair services of household products: The disappearing repair trades and the throwaway society. International Journal of Consumer Studies, 33(6), 619-626. https://doi.org/10.1111/j.1470-6431.2009.00793.x

- Mugge, R., Dahl, D. W., & Schoormans, J. P. L. (2018). “What you see, is what you get?” Guidelines for influencing consumers’ perceptions of consumer durables through product appearance. Journal of Product Innovation Management, 35(3), 309-329. https://doi.org/10.1111/jpim.12403

- Mugge, R., Schoormans, J. P. L., & Schifferstein, H. N. J. (2005). Design strategies to postpone consumers’ product replacement: The value of a strong person-product relationship. Design Journal, 8(2), 38-48. https://doi.org/10.2752/146069205789331637

- Mugge, R., Schoormans, J. P. L., & Schifferstein, H. N. J. (2008). Product attachment: Design strategies to stimulate the emotional bonding to products. In H. N. J. Schifferstein & P. Hekkert (Eds.), Product experience (pp. 425-440). Elsevier.

- Parajuly, K., Kuehr, R., Awasthi, A. K., Fitzpatrick, C., Lepawsky, J., Smith, E., Widmer, R., & Zeng, X. (2019). Future e-waste scenarios. https://wedocs.unep.org/bitstream/handle/20.500.11822/30809/FutEWSc.pdf?sequence=1&isAllowed=y

- Park, M. (2010). Defying obsolescence. In T. Cooper (Ed.), Longer lasting products: Alternatives to the throwaway society (pp. 77-105). Gower.

- Pérez-Belis, V., Braulio-Gonzalo, M., Juan, P., & Bovea, M. D. (2017). Consumer attitude towards the repair and the second-hand purchase of small household electrical and electronic equipment. A Spanish case study. Journal of Cleaner Production, 158, 261-275. https://doi.org/10.1016/j.jclepro.2017.04.143

- Poppe, E., Wagner, E., Jaeger-Erben, M., Druschke, J., & Köhn, M. (2021). Is it a bug or a feature? The concept of software obsolescence. In Proceedings of the 4th conference on product lifetimes and the environment. University of Limerick. https://doi.org/10.31880/10344/10242

- Postma, M., van Kesteren, A., & van der Velden, M. (2019). Repair monitor. Analyse resultaten 2018. https://repaircafe.org/wp-content/uploads/2019/04/RepairMonitor-analyse_2018_02042019.pdf

- Pozo Arcos, B., Bakker, C., Flipsen, B., & Balkenende, R. (2020). Practices of fault diagnosis in household appliances: Insights for design. Journal of Cleaner Production, 265, Article 121812. https://doi.org/10.1016/j.jclepro.2020.121812

- Pozo Arcos, B., Dangal, S., Bakker, C., Faludi, J., & Balkenende, R. (2021). Faults in consumer products are difficult to diagnose, and design is to blame: A user observation study. Journal of Cleaner Production, 319, Article 128741. https://doi.org/10.1016/j.jclepro.2021.128741

- Proske, M., Winzer, J., Marwede, M., Nissen, N. F., & Lang, K. D. (2017). Obsolescence of electronics-the example of smartphones. In Proceedings of the conference on electronics goes green (Article No. 16622100). IEEE. https://doi.org/10.1109/EGG.2016.7829852

- Raihanian Mashhadi, A., Esmaeilian, B., Cade, W., Wiens, K., & Behdad, S. (2016). Mining consumer experiences of repairing electronics: Product design insights and business lessons learned. Journal of Cleaner Production, 137, 716-727. https://doi.org/10.1016/j.jclepro.2016.07.144

- Rames, M., Martin, P., Hansen, S., Gydesen, A., Huang, B., Peled, M., Maya-Drysdale, L., Kemna, R., & van den Boorn, R. (2019). Review study on vacuum cleaners–Final report. https://www.energimyndigheten.se/globalassets/energieffektivisering_/jag-ar-saljare-eller-tillverkare/dokument/produkter-med-krav/dammsugare/vacuum-cleaner-review_draft-final-report-_nov-2018.pdf

- Rogers, H. A., Deutz, P., & Ramos, T. B. (2021). Repairing the circular economy: Public perception and participant profile of the repair economy in Hull, UK. Resources, Conservation and Recycling, 168, Article 105447. https://doi.org/10.1016/j.resconrec.2021.105447

- Rosborou, A. D. (2020). Unscrewing the future: The right to repair and the circumvention of software TPMs in the EU. Journal of Intellectual Property, Information Technology and E-Commerce Law, 11(1), 26-48.

- Sabbaghi, M., Cade, W., Behdad, S., & Bisantz, A. M. (2017). The current status of the consumer electronics repair industry in the U.S.: A survey-based study. Resources, Conservation and Recycling, 116, 137-151. https://doi.org/10.1016/j.resconrec.2016.09.013

- Sabbaghi, M., Esmaeilian, B., Cade, W., Wiens, K., & Behdad, S. (2016). Business outcomes of product repairability: A survey-based study of consumer repair experiences. Resources, Conservation and Recycling, 109, 114-122. https://doi.org/10.1016/j.resconrec.2016.02.014

- Schifferstein, H. N. J., & Zwartkruis-Pelgrim, E. P. H. (2008). Consumer-product attachment: Measurement and design implications. International Journal of Design, 2(3), 1-13.

- Sheeran, P., & Webb, T. L. (2016). The intention–Behavior gap. Social and Personality Psychology Compass, 10(9), 503-518. https://doi.org/10.1111/spc3.12265

- Sonego, M., Echeveste, M. E. S., & Debarba, H. G. (2022). Repair of electronic products: Consumer practices and institutional initiatives. Sustainable Production and Consumption, 30, 556-565. https://doi.org/10.1016/j.spc.2021.12.031

- Stanek, N., Zarębska, M., Biłos, Ł., Barabosz, K., Nowakowska-Bogdan, E., Semeniuk, I., Błaszkiewicz, J., Kulesza, R., Matejuk, R., & Szkutnik, K. (2021). Influence of coffee brewing methods on the chromatographic and spectroscopic profiles, antioxidant and sensory properties. Scientific Reports, 11(1), 1-13. https://doi.org/10.1038/s41598-021-01001-2

- Sunstein, C. (2019). How change happens. MIT Press.

- Svensson, S., Jennifer, H., & Richter, J. L. (2022). A process approach to product repair from the perspective of the individual. Circular Economy and Sustainability, 3, 1327-1359. https://doi.org/10.1007/s43615-022-00226-1

- Tecchio, P., Ardente, F., & Mathieux, F. (2016). Analysis of durability, reusability and reparability: Application to washing machines and dishwashers. European Commission. https://doi.org/10.2788/630157

- Tecchio, P., Ardente, F., & Mathieux, F. (2019). Understanding lifetimes and failure modes of defective washing machines and dishwashers. Journal of Cleaner Production, 215, 1112-1122. https://doi.org/10.1016/j.jclepro.2019.01.044

- Terzioğlu, N. (2021). Repair motivation and barriers model: Investigating user perspectives related to product repair towards a circular economy. Journal of Cleaner Production, 289, Article 125644. https://doi.org/10.1016/j.jclepro.2020.125644

- Thysen, T., & Berwald, A. (2021). Consumers’ experiences with premature obsolescence – Insights from seven EU countries. In Proceedings of the 4th conference on product lifetimes and the environment. University of Limerick. https://doi.org/10.31880/10344/10186

- Van den Berge, R., Magnier, L., & Mugge, R. (2021). Too good to go? Consumers’ replacement behavior and potential strategies for stimulating product retention. Current Opinion in Psychology, 39, 66-71. https://doi.org/10.1016/j.copsyc.2020.07.014

- Van den Berge, R., Magnier, L., & Mugge, R. (2023a). Until death do us part? In-depth insights into Dutch consumers’ considerations about product lifetimes and lifetime extension. Journal of Industrial Ecology, 27(3), 908-922. https://doi.org/10.1111/jiec.13372

- Van den Berge, R., Magnier, L., & Mugge, R. (2023b). The influence of a modular design and facilitating cues on consumers’ likeliness to repair electronic products. In Proceedings of the 5th conference on product lifetimes and the environment espoo (pp. 1115-1121). Aalto University.

- White, K., Macdonnell, R., & Dahl, D. W. (2011). It’s the mind-set that matters: The role of construal level and message framing in influencing consumer efficacy and conservation behaviors. Journal of Marketing Research, 48(3), 472-485. https://doi.org/10.1509/jmkr.48.3.472

- Wieser, H., & Tröger, N. (2018). Exploring the inner loops of the circular economy: Replacement, repair, and reuse of mobile phones in Austria. Journal of Cleaner Production, 172, 3042-3055. https://doi.org/10.1016/j.jclepro.2017.11.106

- Wieser, H., Tröger, N., & Hübner, R. (2015). The consumers’ desired and expected product lifetimes. In Proceedings of the conference on product lifetimes and the environment (pp. 388-393). Nottingham Trent University.

Appendix: The scenarios used in studies 1a, 1b, and 2

| Fault indication - Absent | Fault indication – Present | ||

| Coffee maker (CM) | |||

|

Imagine you own a coffee maker. The coffee maker is a mid-range model, and you own it now for 3 years. Until now, it has had a normal performance compared to similar types of coffee makers. When you wanted to use the coffee maker today, you noticed it failed. It was not able to brew coffee properly. |

|

Imagine you own a coffee maker. The coffee maker is a mid-range model, and you own it now for 3 years. Until now, it has had a normal performance compared to similar types of coffee makers. When you wanted to use the coffee maker today, you noticed it failed. It was not able to brew coffee properly. The coffee maker indicated ‘fault 2’ in its display. The (online) manual indicates ‘the rubber seal of the water reservoir is damaged’ and needs to be replaced. |

| Handstick cordless vacuum cleaner (HCVC) | |||

|

Imagine you own a stick vacuum cleaner. The stick vacuum cleaner is a mid-range model, and you own it now for 3 years. Until now, it has had a normal performance compared to similar types of stick vacuum cleaners. When you wanted to use the stick vacuum cleaner today, you noticed it failed. It would not turn on and did not function anymore. |

|

Imagine you own a stick vacuum cleaner. The stick vacuum cleaner is a mid-range model, and you own it now for 3 years. Until now, it has had a normal performance compared to similar types of stick vacuum cleaners. When you wanted to use the stick vacuum cleaner today, you noticed it failed. It would not turn on and did not function anymore. A red-light icon appears on the stick vacuum cleaner when placed in the charging station. The (online) manual indicates ‘the battery is damaged’ and needs to be replaced. |

| Cylinder vacuum cleaner (CVC) | |||

|

Imagine you own a vacuum cleaner. The vacuum cleaner is a mid-range model, and you own it now for 4 years. Until now it has had a normal performance compared to similar types of vacuum cleaners. When you wanted to use the vacuumcleaner today, you noticed it had lost its suction power, and did not function properly anymore. |

|

Imagine you own a vacuum cleaner. The vacuum cleaner is a mid-range model, and you own it now for 4 years. Until now it has had a normal performance compared to similar types of vacuum cleaners. When you wanted to use the vacuumcleaner today, you noticed it had lost its suction power and did not function properly anymore. A red-light icon appears on the vacuumcleaner. The (online) manual indicates ‘the filter is damaged’ and needs to be replaced |

| Washing machine (WM) | |||

|

Imagine you own this washing machine. The washing machine is a mid-range model, and you own it now for 6 years. Until now, it has had a normal performance compared to similar types of washing machines. When you wanted to use the machine today, you noticed it failed. You were not able to activate the wash programs anymore. |

|

Imagine you own this washing machine. The washing machine is a mid-range model, and you own it now for 6 years. Until now, it has had a normal performance compared to similar types of washing machines. When you wanted to use the machine today, you noticed it failed. You were not able to activate the wash programs anymore. The washing machine indicated fault 5 in its display. The (online) manual indicates ‘the drum bearings are damaged’ and need to be replaced. |