Embracing Material Surface Imperfections in

Product Design

Owain Pedgley 1,*, Bahar Şener 1, Debra Lilley 2, and Ben Bridgens 3

1 Department of Industrial Design, Middle East Technical University, Ankara, Turkey

2 Design School, Loughborough University, Loughborough, United Kingdom

3 School of Architecture, Planning & Landscape, Newcastle University, Newcastle, United Kingdom

Imperfection is not a usual aim within the context of industrialized product design. Under general norms, products are manufactured as clones of a ‘perfect’ original and product surfaces are prized for their ‘perfect’ flawless state. The mass production of products against these principles seems counterintuitive. Yet within the world of materials, and especially considering material surfaces, imperfection is widespread. This research set out to identify and scrutinize circumstances when material imperfection in products is appreciated, from mass manufacture to artisan practices. By synthesizing literature with analyses of material and product samples, five sources of surface imperfections are characterized: inherent material properties, production effects, workmanship of risk, planned and foreseen events, and everyday wear and tear. Following this, a research-focused concept design project is reported, leading to eleven product designs that exemplify how to design for, and with, imperfect material surfaces. A significant challenge facing designers is one of persuasion: of designing products where imperfect material surfaces are regarded as contributing to rather than detracting from product value. To this end, the paper culminates in a visual guide to embracing material surface imperfections in design practice.

Keywords - Materials, Surfaces, Imperfection, Product Design, Experiences.

Relevance to Design Practice – Product designers should not instinctively dismiss materials possessing imperfect material surface qualities. Following guidance in this paper, material surface imperfections can contribute to positive user experiences and open new commercial opportunities.

Citation: Pedgley, O., Şener, B., Lilley, D., & Bridgens, B. (2018). Embracing material surface imperfections in product design. International Journal of Design, 12(3), 21-33.

Received May 3, 2017; Accepted May 30, 2018; Published December 31, 2018.

Copyright: © 2018 Pedgley, Şener, Lilley, & Bridgens. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: pedgley@metu.edu.tr

Owain Pedgley is Full Professor of Industrial Design at Middle East Technical University, Turkey. His academic expertise centers on design for product interaction and experience, notably within the emerging domain of materials experience. Between 2014-2017 he was a founding member of the Industrial Design program in the School of Engineering, University of Liverpool, UK. He is a strong advocate and early practitioner of academic research conducted through design. Prior to his academic career, Owain worked as a product designer in the sports equipment and musical instrument sectors and co-founded the guitar innovation venture Cool Acoustics.

Bahar Şener recently re-joined the Department of Industrial Design at Middle East Technical University, Turkey, as Full Professor. Previously, she was a founding academic for the BEng (Hons) Industrial Design program offered jointly between the University of Liverpool (UK) and Xi’an Jiaotong-Liverpool University (China). Her research spans design for rich product experiences, digitalization of industrial design processes, and design for wellbeing. Bahar has contributed to and supervised a substantial portfolio of design and innovation projects in collaboration with national and international companies including Arçelik, BSH, Vestel, Procter & Gamble, and Bentley Motors Ltd.

Debra Lilley is a Senior Lecturer based in the Design School at Loughborough University, whose research focuses on people’s attitudinal responses to materials which have changed through time and use, and how these attitudes inform their behavior within the context of the circular economy. She is currently developing resources to enable designers to better understand and exploit material change as a tool to engender emotional attachment and longer product lifetimes.

Ben Bridgens is a structural engineer based in the School of Architecture, Planning & Landscape at Newcastle University, whose research focuses on the role of materials in design, making, and experience. Collaborations with product designers, artists, and architects have enabled him to apply technical expertise in material testing and characterisation, material ageing, responsive materials and lightweight tensile structures to broader questions of sustainable design, consumption and the circular economy. He is currently exploring how materials change through the lifetime of an object or building, and how better understanding of this material metamorphosis could be used to create emotionally durable artefacts.

Introduction

Deyan Sudjic, Director of the Design Museum in London, proposed the theme imperfection for the inaugural Istanbul Design Biennial in the fall of 2012, an event that formed the catalyst for conceiving and developing this present work. In industrialized product design, a sense of imperfection can originate from a wide range of physical product attributes, for example form, proportions, comfort, and—for the focus of this paper—materials (Ostuzzi, Salvia, Rognoli, & Levi, 2011).

Sudjic (2012) explained that the pursuit of imperfection requires explanation for each discrepancy and demands that the designer justify why a perceived norm—that is, repetitive cloning in the context of industrial production—was deliberately avoided, as the following passage explains:

For a designer the tricky thing about looking for the qualities of imperfection is the demands it places on them to justify aesthetic decisions. Perfection is an aspect of an object that while it may not be easy to achieve, is conceptually straightforward. ln the age of mass production, perfection has been taken to mean the ability to make hundreds, thousands or even millions of objects that are all exactly the same. The word itself suggests the existence of an original [a standard], with the special qualities that implies. Such objects are understood as perfect copies of something else, rather than objects that are to be understood as having their own individual qualities… (Sudjic, 2012, para. 3)

In the industrial manufacture of product components, quality is correlated to consistency. Should variations occur during manufacture, deviating from the product specification, the likely outcome is rejection of the offending component. The near-zero tolerance for variability is understandable when considering user experiences: in the world of clones, all customers receive an identical product, displaying known and pre-stated performance and aesthetic qualities. Everybody’s purchase is perfectly the same: a principal theme of conventional mass production, which remains the de facto approach in today’s manufacturing industries (Pedgley, 2009, 2014).

But must this be accepted without question? Can we credibly champion imperfection as a desirable product attribute within mass manufacture? Would it be the antithesis of conventional production ethics, or would it be—as we argue throughout this paper—more of a new take on an existing platform, embracing partial deviation instead of cloning?

The aesthetics of imperfection is not necessarily distant from the practicalities of conventional mass manufacture. Sudjic (2012) provides some practical possibilities: “…shiny glossy surfaces can be replaced by lesser degrees of polish. Pure geometry is not the only possible formal language. Pure color can give way to muddy mixes. Symmetry is not the only option” (para. 4). Comparisons can be drawn with moves within the skincare and fashion industries to adjust their marketing away from a stereotypical slim model with perfect skin towards a body image and skin qualities that more realistically depict human variety and ageing. A high-profile example is the global Unilever/Dove Campaign for Real Beauty.

Many new product creation technologies and systems are emerging to complement mass production, e.g., bespoke products (Campbell, Hague, Şener, & Wormald, 2003), at-home 3D printing, DIY materials (Rognoli, Bianchini, Maffei, & Karana, 2015), and online customization. New social, cultural and environmental issues are also influencing the renewal of our material world. In the present era, it is right and proper to question whether a move away from the cloned product towards the materialistically unique product can bring benefits. The answer is multifaceted. Certainly, the shift towards more sustainable resources, production and living can be a major driving factor, delivering products having appreciable and distinct aesthetic qualities directly linked to improved sustainability credentials (Datschefski, 2001; Saito, 2007; van Hinte, 1997; Walker, 1995). Personal satisfaction is another important factor: the satisfaction that can arise from owning, using, and admiring a product unlike any other, being captivated by its individual character and how its ‘flaws’ translate to essential character qualities.

Rognoli and Karana (2014) suggest that present modes of industrial production can indeed be challenged if we consider the idea that material-based product imperfection should not be instinctively rejected but instead embraced as a legitimate way to bring about product differentiation (even individualization) and new product experiences. The research presented in this paper contributes a theoretical structure to the body of work on material imperfection—especially in relation to surface design, allied to practical examples of how designers can take action in the area. People’s perspectives on how products ought to be materialized and the kinds of experiences they should expect can be challenged by informed designers. The following research questions were posed to guide the work, which was made through a combination of literature review and practice-based design research.

- In what ways can a material be imperfect?

- When in the material-product lifecycle can surface imperfections occur?

- Under what circumstances does an imperfect material surface add value and when does it detract?

- What assistance can be given to designers to use material surface imperfections as a desirable product attribute?

Material as Perfect or Imperfect

Material (im)perfection exists in both the physical world of products and in the perceptual and cognitive world of the beholder of those products. A product-oriented definition of imperfection refers to factual and observable properties of matter, whereas a user-oriented definition refers to experiential and judgmental constructs of individuals and people. To set a foundation for the study, we reviewed the nature of material imperfection from both product-oriented and user-oriented positions.

Product-Oriented Definition

The literature converges on the point that a product material is considered perfect when it satisfies one or both of the following conditions.

- Excellently suited to the functional parameters of a product: a perfect material choice, given the design requirements.

- Has a uniform surface quality: a perfect material complexion.

By reversing the meaning of these conditions, we can reach a product-oriented definition of material imperfection. With the first condition, imperfection would imply a material choice that is not excellently suited to the functional design requirements. General wisdom in product design holds that material choices should not compromise the proper functioning of the product. For example, there is little point in using a material with a low melting point for high-powered lighting fixtures; or allowing the structural integrity of outdoor play equipment to be compromised by specifying unfinished mild steel. The concept of material affordances (Fisher, 2004; Norman, 2013)—referring to the possibility to harness performative qualities of materials to benefit product design—is relevant to this discussion. A transparent glass window affords seeing through, in a way that opaque polyethylene does not. A malleable expanded polystyrene bean bag affords relaxed sitting, in a way that a wooden framed kitchen chair does not. So although it is true that a material can be deemed a perfect choice for realizing a product function, the opposite isn’t really imperfect but rather straightforwardly poor or incorrect. Under this condition there is no scope for serious design exploration.

The second condition is more promising: the concept of a non-uniform surface and an imperfect material complexion. Boradkar (2004) uses the term product skin to reference the sensorial qualities of materials that outwardly communicate to users. This is an important concept but comes with reservations. Materials always have inner matter. Considering the haptic aspects of material interaction, the underlying matter below the skin cannot be ignored. For example, a polyurethane armrest can be soft or hard irrespective of the qualities of its skin, depending upon the exact material formulation used, its processing, and the geometry of the part. Although designers are especially concerned about the visual and tactual definition of materials, this is not to the exclusion of an integrated approach to form, function and interaction. For a designer, materials are not a superficial matter; they are part of the total user interface of a product. But if we take the second condition forward, we arrive at a definition of material imperfection as being surface qualities that are not homogenous or not consistent from one region to another, creating an irregular effect. This definition fits to many traditional as well as new and emerging materials. The scope for design exploration is considerable and forms the focus for the research presented in this paper.

User-Oriented Definition

When moving to the subject of user experience, and the idea of a perfect material as a user impression or experience, the situation is more complex than presented from a product-oriented definition. An overarching issue is ‘perfect for whom?’ People experience materials on multiple levels—aesthetics, meanings, emotions, and behaviors (Giaccardi & Karana, 2015; Karana, Pedgley, & Rognoli, 2015), combining past experiences with the here-and-now, resulting in complex material stories that can be highly personal and unpredictable.

It is well established that material judgments are made not by considering a material in isolation, but instead with reference to its application and intended usage scenarios and environments: so-called contextualized material (Karana & Hekkert, 2010). It will also be appreciated that during product use, the temporal dimension is an important factor on the kinds of user experience that will be reported from a product, from initial impression at first encounters to longer-term product ownership and reliance, and from visceral responses to more reflective judgements (Karapanos, Zimmerman, Forlizzi, & Martens, 2009; Khalaj & Pedgley, 2014; Schifferstein & Hekkert, 2008). From an experiential perspective, the context and timing of exposure to material imperfections is likely to be crucial.

Whilst irregularities on material surfaces will often have no effect on the serviceability of that material, it is people’s reaction to the irregular appearance that is telling. The phrase ‘perfectly imperfect’ is useful here: an observably imperfect material surface being experientially perfect. For example, imperfectly shaped fruits and vegetables are notoriously rejected for supermarket consumption, despite being as tasty and nutritious as their perfectly shaped counterparts. In the United Kingdom, the major retailer Tesco introduced a low-priced Perfectly Imperfect range of fruit as a means of nationwide distribution of produce that would otherwise be rejected (see Tesco website, https://www.ourtesco.com/2016/04/14/our-perfectly-imperfect-range). In the USA, companies specialize in making proper culinary use and distribution of ugly fruit and vegetables (see Imperfect produce website, http://www.imperfectproduce.com). Imperfect material surfaces may split opinion on the matter of valence: on whether one tends to have a negative or positive outlook on a particular imperfection. For some, an imperfection may be viewed as faulty or incomplete, whilst for others it may be viewed as unique or original. The latter is the positive outlook adopted for this research, resonating with the ancient Japanese concept of wabi-sabi (circa 900AD): the aesthetic appreciation of “things imperfect, impermanent, and incomplete” (Koren, 2008, p. 7) against a backdrop of the ingenuity and efficacy of the natural world (Juniper, 2003). The closest translation of wabi-sabi in English is ‘rustic’, pointing to simple rural charm and rough use of natural materials. But this brings misplaced connotations of a particular style and context (e.g., farmhouse style, cottage style), whereas wabi-sabi is a more elusive and stylistically independent concept that has potential benefit for examining how imperfection might be more widely appreciated in design (Rognoli & Karana, 2014).

Sources of Material Surface Imperfections

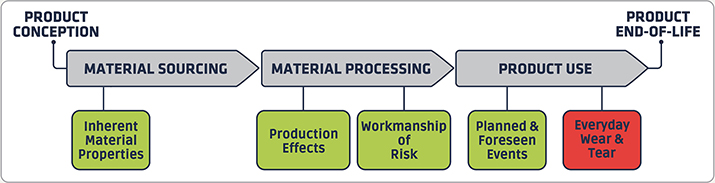

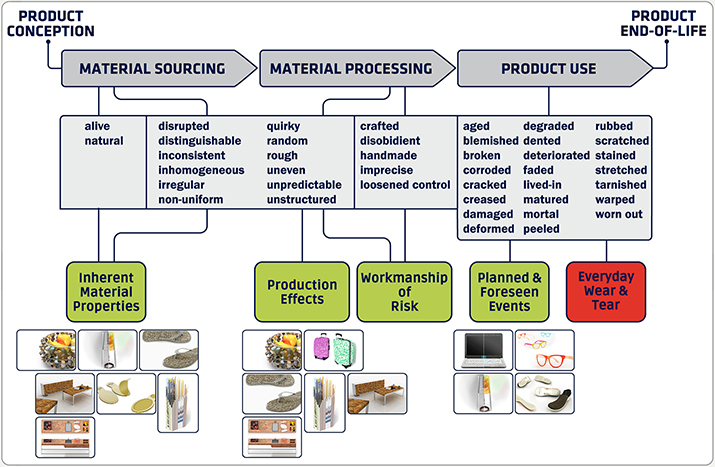

The process of identifying sources of material surface imperfections commenced with an immersion in relevant literature spanning imperfection and design. Material-related discussions and product examples were extracted during that immersion, with the results subsequently being mapped to conventional product lifecycle stages. What resulted was a clear picture of where material experiences can be implicated with imperfection: (i) during materials sourcing (where materials can be inherently imperfect), (ii) during material processing (where variability in material shaping and finishing can cause imperfections), and (iii) during product use (where interactions with material surfaces can cause imperfections). Figure 1 formalizes these results into five distinct sources of material imperfection, each linked to a particular product lifecycle stage. The five sources are now analyzed individually in depth.

Figure 1. Sources of material surface imperfections mapped onto abridged product lifecycle.

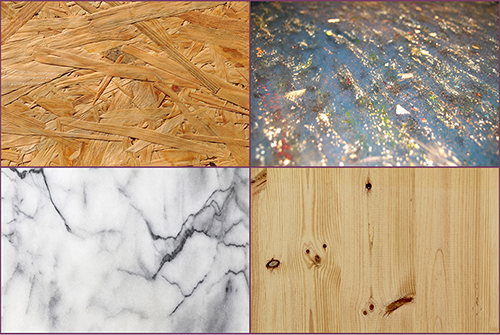

Inherent Material Properties

For this source of surface imperfection, material heterogeneity is built-in to a raw or semi-finished material (Figure 2). The material arrives in a heterogeneous state regarding its properties and sensorial qualities. Natural materials such as wood, stone and leather impart substantial individuality in mass-manufactured products. Wood has grain, figure, color and texture that is unique from piece to piece. These qualities are highly appreciated in wood products (Hoadley, 2000; Kotradyova, Teischinger, & Ebner, 2012). With their inherent variability, surface complexity, and resilience, natural materials in general avoid a clear distinction between being obviously new and obviously worn, thus creating a low risk of short term dissatisfaction (Lilley, Smalley, Bridgens, Wilson, & Balasundaram, 2016). Recycled plastics, grown bio-materials, and natural fiber composites commonly have heterogeneous material qualities and material surface disturbances.

Figure 2. Material surface imperfections inherent to synthetic and natural material surfaces.

Clockwise from top left: chipboard (© Petr Cihak | Dreamstime.com), recycled polycarbonate from discarded compact discs, pine (© Jordi Clave Garsot | Dreamstime.com), marble (© Siloto | Dreamstime.com).

Production Effects

Many industrial manufacturing processes inherently leave traces of the production process on the forms that they create. Injection molded components, for example, can exhibit knit lines or splay, which in effect are disorganized industrial defects or blemishes that nevertheless can be embraced as a way to achieve standard unique products that might otherwise be rejected (Salvia, Ostuzzi, Rognoli, & Levi, 2010). Furthermore, by relinquishing tight control of shaping and surface treatment processes, tolerated imperfections within the material form and finish of a product can be achieved. In essence, the loosening of control introduces a random dimension to the connection of product design and manufacture (Pedgley & Şener, 2012), providing dramatic or subtle material differentiation irrespective of volume of production (Figure 3).

Figure 3. Surface imperfections achieved through randomized material shaping and finishing.

Clockwise from top left: Vectric surface texturization (© Vectric Ltd), Desma boots (© DESMA Schuhmaschinen GmbH), Malfunktion (© efealpay.com), Edra/Traag Sponge Chair (© Quittenbaum Kunstauktionen GmbH).

For the Sponge polyurethane armchair by Peter Traag for Edra, the product form and surfaces are built up through multiple free-flowing irregular folds in the upholstery. A range of molded polyurethane boots by Desma are created by the company’s color modulation technology, resulting in pronounced color swirling. In Malfunktion, real-time manual intervention into the usually predictable and repetitive 3D printing process is made, resulting in surface imperfections (Alpay, 2013). Prior to manufacture, at the stage of CNC (computer numerically controlled) machine code programming, randomness within software algorithms can be used to define unique machined surface patterns and textures on natural or synthetic materials (see Vectric website https://www.vectric.com). It should be noted that three of the four shaping processes in Figure 3 do not involve fixed cavity molds, since surface finish variability alongside form variability is impractical to achieve. Instead, all (except the Desma boots) make use of additive or subtractive technologies operating with far fewer physical constraints.

Workmanship of Risk

Prior to the Industrial Revolution, most objects were hand crafted. Irregularity and individuality were ubiquitous, described by Pye (1968) as the workmanship of risk, “in which the quality of the result is not predetermined, but depends on the judgement, dexterity and care which the maker exercises as he works” (p. 20). For artisans and craftspeople regularly involved in making one-off or small batch products, individuality through materialization was/is a customary characteristic. Variability in crafted products is a central source of value, such as hand-stitched leather or hand-painted ceramics (Figure 4).

Figure 4. Surface imperfections in handcrafted pottery introduced by a craftsperson through workmanship of risk.

(© Thomas Holt | Dreamstime.com)

For hand crafted products, there is often a spiritual dimension associated with the unique artefact; its origin being the care, skill, and effort imparted by the maker. Craftspeople are intimately familiar with the affordances of their chosen material, knowing how to orchestrate the transformation process from material to product (Falin & Falin, 2014). However, Pye (1968) cautions that “the workmanship of risk has no exclusive prerogative of quality. What it has exclusively is an immensely various range of qualities, without which at its command the art of design becomes arid and impoverished” (p. 23). So it would not be straightforward to cross this source of imperfection over into mass production, by definition. It perhaps can be considered for batch or low volume production, where manual intervention of a highly skilled nature (not casual or random) can complement industrial processes—a kind of ‘extra-perfection’ where there is appreciated variation from one product to the next. McCartney (2016) describes the situation thus: “what we have… is a post-industrial nostalgia for the pre-industrial. In a culture with a surfeit of branding and cheap mass-produced goods, we romanticize the handmade because we yearn for quality, not quantity” (McCartney, 2016, p. 146).

At the arrival of the Industrial Revolution, mechanization brought repeatability and workmanship of certainty. Craftsmanship gave way to mass-produced objects, which strived to be homogeneous, repeatable, and perfect (Woolley, 2003)—essentially the foundation of the prevailing ethos within modern manufacturing.

Planned and Foreseen Events

It is sometimes the case that a material or a product in its newly-manufactured state is not the state that is most valued by people. Putting aside discussion of antiquity (i.e., monetary value through ageing), there are many examples where the effects of use on a material contribute to other kinds of values. For example, running shoes or hiking boots need to conform to their owners’ feet before they can offer the best comfort and performance for competing in a race or climbing a mountain. Such breaking-in of products is a planned part of the product lifecycle, whereupon the cloned surfaces of the production line become purposefully disfigured over time. Much the same can be said for a comfortable sofa, which over considerable time leaves a trace of its owners’ preferred posture. The surface imperfections in such cases tells a positive story of use. It is supposed to happen—moreover, it is desirable to happen, and is entirely predictable.

Materials also change in predictable ways in response to the natural environment: moisture, light, temperature, growth of mold and fungi, and reaction with oxygen and other chemicals in the atmosphere. Different stimuli are important for different classes of materials: metals oxidize, plastics degrade when exposed to ultraviolet light, wood decomposes in response to UV and is prone to fungal growth (Figure 5). These stimuli combine to create a surface patina that discloses the life of the object (Baxter, Aurisicchio, & Childs, 2016; DeSilvey, 2006; Giaccardi, Karana, Robbins, & D’Olivo, 2014; Nobels, Ostuzzi, Levi, Rognoli, & Detand, 2015). There is a dichotomy in how such a patina is interpreted—it can result in dissatisfaction, or it can be a source of emotional bonding to the object. Oxidation of steel results in flaky and weak rust, whereas for copper oxidation results in a hard wearing and distinctive green patina. Ultraviolet light damages the structure of wood, but in doing so accentuates the surface texture and grain pattern. Through such processes, a once uniform material surface can transition into a unique object with an imperfect surface. Ageing of most plastics involves both aesthetic and functional decay—fading colors, yellowing, scratched surfaces and embrittlement (Fisher, 2004; Shashoua, 2008). There is perhaps an expectation that synthetic materials should remain pristine, whereas there is greater acceptance that natural materials will change, as expressed by one of the participants of the Proud Plastics survey initiated by the Eternally Yours Foundation: “It is OK for wood to become old and dirty. You can’t blame it; it is its nature. But plastics were invented. So when they become ugly, when they melt or crack, you blame the inventors. They should have done a better job” (van Hinte, 2004, p. 285).

Figure 5. Material surface imperfections arising from a particular foreseen event or way of use.

Clockwise from top left: copper lamppost with sulphate patina (© Kyrien | Dreamstime.com), worn-in hiking boots (© Les Cunliffe | Dreamstime.com), copper kettle with oxide patina (© Sergeka | Dreamstime.com), wood exposed to weathering (© Anastasiia Ivanskaia | Dreamstime.com).

To keep within the paradigm of material perfection, designers will often try to stifle the encroachment of material decay or degradation by selecting durable coatings, scratch-resistant materials, light-resistant pigments, etc. This is in stark contrast to the concepts of graceful ageing and maturing, where materials obtain a worldliness through accumulation of years of interaction (Candy, Sommerville, Kalviainen, & Oksanen, 2004).

Emotionally durable products (Chapman, 2009) are highly related to these discussions. Many interacting factors mediate the response to a changing material, for example: the type of material, product context, cultural influences, the rate at which the material changes, duration of ownership, the provenance of the object, and whether the object has been cared for and maintained. Semantics is important here. “Some materials ‘degrade’ while others ‘mature’ by maintaining or improving certain qualities. The positive term of maturity is usually used for natural materials such as stone, paper, wood, and leather, which over the years can acquire scents, colors, and textures: characteristics that far from diminishing their quality, instead acquire an aura of antiquity and preciousness” (Rognoli & Karana, 2014, p. 151).

This increase in value is driven by the scarcity and individuality of imperfection. Some materials need to be worn-in before they reach a satisfactory expression or appearance, echoing the functional breaking-in mentioned earlier: brand new sometimes just does not give a good look. It is intriguing and relevant to note that in circumstances where ageing is valued, Candy et al. (2004) contend that ageing cannot be faked. Sensorially, they say, people are too clever to accept a fake. Even though convincing examples might be sensorially authentic to long-term usage, such as distressed denim given a worn in (imperfect) appearance at the factory, it is the lack of responsibility on the owner for the aging effects that causes experiential dissonance.

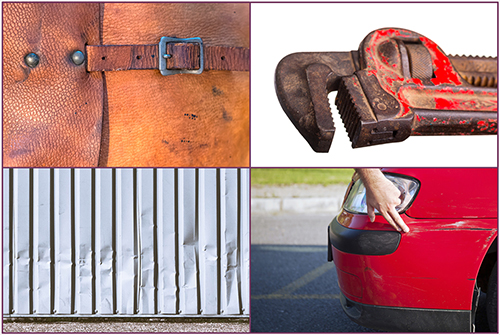

Everyday Wear and Tear

Despite industrial designers’ and manufacturers’ best efforts to produce identical, flawless products, from the moment of purchase a complex interaction of physical, chemical and biological processes result in changes to a material surface (Figure 6). Conceptually this is no different to environmental or human temporal effects on materials within the urban landscape or buildings (Kolarevic & Klinger, 2008). The fundamental point is that materials change: “…the formal language of design has notably shifted to a space dominated by the smooth and opaque surface. Such impenetrable surfaces make it easy to forget that the materials from which it was made are kinetic, that it is their ‘will’ to decay or change state” (Carr & Gibson, 2016, p. 305).

Figure 6. Everyday wear and tear.

Clockwise from top left: tarnished leather bag (© Dean Neitman | Dreamstime.com), peeling paint hand tool (© Derejeb | Dreamstime.com), scratched car (© 123elis | Dreamstime.com), dented fence (© Thomas Gowanlock | Dreamstime.com).

The physical interaction of people and products with regard to product surface degeneration is poorly understood (Lilley et al., 2016). People owning the same product will experience different patterns and signs of wear on the material surfaces. The effect of this interaction on objects is referred to as wear and tear, which covers a range of surface changes described in the Taxonomy of Damage by Manley, Lilley, and Hurn (2015): impact, ablation (chipping of the surface), abrasion (scratching and polishing), and accumulated dirt. Wear and tear does not imply a lack of care on the part of the product owner. The first scratch on new shoes, or the first knock on a new car is a short-lived trauma that gives way to an acceptance that wear and tear is an inevitable part of owning and using a product. The timing and source of surface damage is not predictable by the designer, hence when first introduced in Figure 1 everyday wear and tear is highlighted in red as a special case.

In the “scratch-free world of slick polymers” (Chapman, 2014, p. 141) any change to a synthetic material surface, such as abrasion or scratching, is commonly interpreted as damage, which can result in dissatisfaction and fuel the cycle of premature replacement. Scratching and wear to the surface of electronic devices is almost always seen as degradation, whereas signs of use (Salvia et al., 2010) or traces of life (Karana, 2012) on sports equipment and musical instruments are seen as “a type of material history—in part procured [by] a deeper sense of care and involvement between participants and their things by inscribing a unique and personal semantic narrative into the objects through material experiences of use” (Odom & Pierce, 2009, p. 3796).

Here there is an important distinction between private possessions and public property, which becomes increasingly relevant with the rise of the sharing economy. Surface imperfections that have arisen through other people’s use of a product are unlikely to be so well tolerated. The concept of contaminated interaction becomes central (Baxter et al., 2016). A worn and no-longer perfect sofa at home may bring positive thoughts because the owner created the wear and it reminds them of the good times spent there. On the other hand, a worn seat on a train or bus might only arouse negative thoughts about bad maintenance, low quality materials or a sense of over-use.

For wear and tear, or changes attributable to an object’s environment, a gradual, almost imperceptible transition of the surface, which starts a respectful time after purchase, is more likely to be perceived as a valuable patina. Sudden changes to an object’s surface, particularly accidental damage soon after purchase, will usually be seen as negative, e.g.: “...I’m pretty protective over it for the first couple of weeks and then after that you don’t really notice damage so much” (Manley et al., 2015, p. 5). However, if the stimulus for change is a notable event within a positively appraised context (for example a particular occasion when using an item of sports equipment or a tool) then sudden change may be more acceptable, as it builds a narrative around the object (Odom & Pierce, 2009).

There are some signs that wear and tear might be tolerated well within the emerging repair shop culture, where functionally compromised products can be given new life. Maintenance and modification provide opportunities to go beyond passive consumption to a “highly productive and creative appropriation of those goods which transformed them over time” (Tilley, Keane, Küchler, Rowlands, & Spyer, 2006, p. 348). In Western cultures repair is usually carried out with the aim of making the object as good as new. In contrast, the Japanese art of Kintsugi (golden joinery) celebrates the repair and makes the breakage part of the history of the object (Keulemans, 2016). Recently this has been paralleled in the West by Sugru—a brightly colored product that enables highly functional, but also ostentatious, repairs and modifications to be made to a wide range of materials. This provides an example of imperfection being celebrated as an improvement due to the unique, personalized nature of the repaired object, and also the effort invested by the owner or repairer.

From Principles and Categories to Design Practice

The five sources of surface imperfections as presented were defined through a detailed analysis of literature and product examples, within the frame of a general product lifecycle. Their identification represented completion of one part of the study. What remained to be seen was whether the sources would be relevant to design practice. To this end, the second part of the study comprised a concept design project, purposefully set up to allow an independent assessment of the suitability of the five sources of imperfection. Rather than exposing designers to the five sources, the methodology was to allow designers freedom to explore and create on the theme of material surface imperfections. Then, retrospectively, an analysis would be made of their concept design proposals to determine which—if any—of the five sources had been exemplified. The concept design project spanned seven weeks and was organized under the umbrella of the Istanbul Design Biennial Academy Program theme of Imperfection. It was later publicly exhibited at the inaugural Istanbul Design Biennial between October and December 2012. The project is presented here as a case study.

Design for Positively Appraised Material Surface Imperfections

The aim of the project was to generate product designs emphasizing material surface imperfections, providing a modest platform for provoking and challenging society’s prevailing values regarding material perception and perfection in everyday products. Eleven MSc and PhD industrial design students at Middle East Technical University participated in the project, which involved an initial orientation phase followed by an ideation phase. The project was supported by formal lecture inputs, class exercises, take-home assignments and design critiques within the graduate module ID725 Materials Experience.

Orientation Phase

Participants were asked to bring A4 printouts of products that they considered to have perfect and imperfect materials. This involved independent investigation by each participant, who set their own criteria for characterizing perfection and imperfection following a class discussion and a show-and-tell session on physical products and material samples that they brought to class.

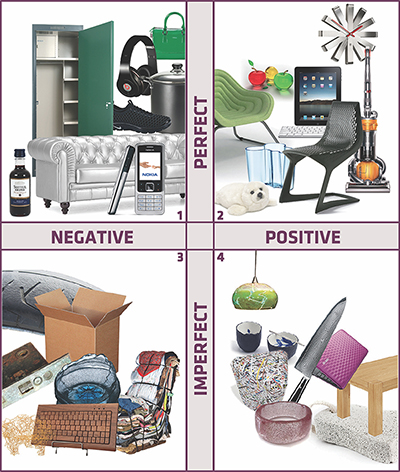

A class analysis of the ≅100 A4 product printouts was then initiated, with the aim of categorizing the products in a way that could define the design space for material imperfection. It became clear that participants differed markedly in their opinions of the products and that aside from perfect-imperfect, other criteria were needed to capture diverse views. A collaborative effort between instructors and participants was therefore initiated to reach consensus on the process of categorization. The preferred categorization was to create a plot with two axes. On a large working space, variations in x-y axes were defined onto which each product could be positioned, discussed, and repositioned as necessary (Figure 7). The eventual settled axes were ‘negative impression—positive impression’ (x-axis) and ‘perfect material surface—imperfect material surface’ (y-axis).

Figure 7. Snapshot of A4 product printout positioning during analysis of material imperfections.

The x-axis provided a simple measure of subjective valence, whilst the y-axis helped to position the product materials based on a factual (objective) description of surface properties. As is to be expected, the y-axis classification was relatively straightforward whilst the x-axis classification prompted much debate and difference of opinion, principally because of participants’ differing perspectives on which kinds of materials seemed appropriate for which kinds of products. In the end, an agreement to disagree amongst a minority of participants was sometimes necessary. The final x-y plot was created on a majority decision and provided four qualitatively distinct quadrants, as illustrated in Figure 8 and described as follows.

- Quadrant 1 (Negative-Perfect) contained products with perfect material surfaces that most participants viewed negatively. The perfection typically led to products being judged as too synthetic, too controlled, too predictable, too sterile, too boring, kitsch, overused or cliché.

- Quadrant 2 (Positive-Perfect) contained products with perfect material surfaces that most participants viewed positively. The perfection was usually linked to remarkable material properties, such as being strikingly flat, having mirror-like gloss, displaying superior engineering, or having exceptional control over detail and quality.

- Quadrant 3 (Negative-Imperfect) contained products with imperfect material surfaces that most participants viewed negatively. The imperfection for these products was unwelcome for reasons such as ungraceful ageing, unfinished appearance, tasteless application, and defective quality.

- Quadrant 4 (Positive-Imperfect) contained products with imperfect material surfaces that most participants viewed positively. The imperfection for these products typically added value through product uniqueness and the charm or wit of individual character. Participants were told to target their own product concepts to quadrant 4, and advised that products within the quadrant exemplified what might be possible from their own designs.

Figure 8. Material (im)perfection categorized into four quadrants (collages © Yekta Bakırlıoğlu).

The plotting of products was an important orientation study for the participants prior to requesting their creative design input, helping them to develop a critical eye between material properties, imperfection judgements and resultant user experiences.

Ideation Phase

Having forged a group understanding of the potential value of material surface imperfections during the orientation phase of the project, participants were ready to individually design and visualize a creative product solution built explicitly on the adoption of material surface imperfections.

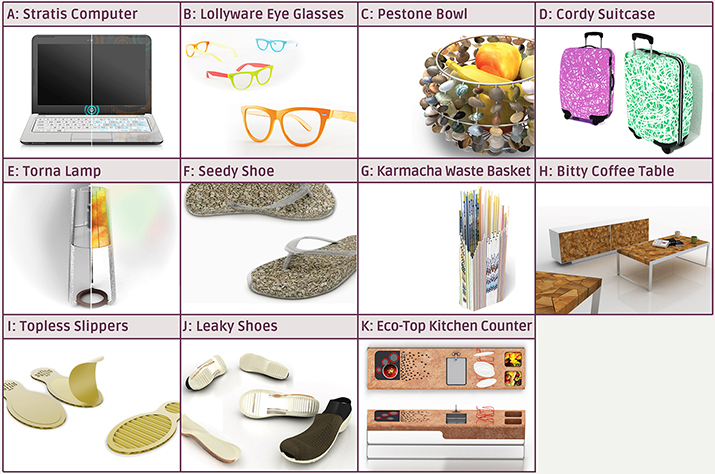

The objective in participants’ product design work was to arrive at a concept that fitted into quadrant 4 in Figure 8: possessing an imperfect material surface that would leave a positive product impression. Participants were free to define their own starting point. For example, an existing product in any of the other quadrants 1-3 having potential to migrate into quadrant 4; or, any other product sector they considered would benefit from imperfect surfaces. Eleven conceptual product designs [A-K] were proposed, one from each participant. Figure 9 provides a gallery of all the designs.

Figure 9. Gallery of concept product designs.

Discussion: Designing with and for Material Surface Imperfections

Each of the product concepts is now introduced, emphasizing the individual participants’ rationale for the adoption or creation of imperfect material surfaces.

The product finishing for the Stratis Computer [A] comprises multiple layers of semi-permanent colored patterns. Fresh new layers are revealed by the removal of upper layers through daily wear and tear or intentional surface rubbing. The overall result is a grunge visual effect that becomes more intense over time. The arms of the Lollyware Eye Glasses [B] have a roughened irregular texture made from a sweet food-based resin. Observation of spectacle wearers revealed the common habit of biting the spectacle arms. The product exploits this behavior, giving users a sugar boost on each bite, whilst exaggerating the irregular appearance. Each pebble in the Pestone Bowl [C] has a unique irregular form and surface qualities, creating a unique visual and tactual experience for each bowl. Furthermore, the order of the stones and their ability to rotate about a wire, provide endless ways to play with and re-configure the product.

The use of freely extruded thermoplastic in constructing the exoskeleton of the Cordy Suitcase [D] results in imperfection not only close-up in the solidified material surface but also in the larger-scale sinuous suitcase structure. This highly characterful exoskeleton is achieved by manual intervention in directing a plastic extrusion head over an open mold. The Torna Lamp [E] is a re-interpretation of an IKEA product, using materials that have inherent imperfect surfaces: wood, aluminum foam, and temperature-sensitive glass able to chromatically change based on ambient temperature as the bulb brightens and heats up. The goal was to achieve irregularity across multiple sensory modalities: not just visual but also irregular thermal conductivity and surface texture. In Seedy Shoe [F], the use of seeds as a soft filler material creates visual and tactile non-uniformity. Combinations of different seed varieties, each having variegated or distinctive colors, results in further diversity in sensorial effects.

Assembled from thin rolled strips of recycled paper of random length, the Karmacha Waste Basket [G] has a multi-colored and random printed appearance, a somewhat vulnerable surface quality, and an asymmetrical form. Philosophically, the product made of waste becomes a receptor for more waste. The work surface of the Bitty Coffee Table [H] is created from off-cut wood pieces shaped into non-uniform profiles and joined together with adhesive. Each piece has visual and tactile irregularities, but the table as a whole is harmonious. Corrugated cardboard, with its rough and varied surface, is used for the hotel Topless Slippers [I], accentuating the product’s vulnerability and disposability. Inside the sole of the Leaky Shoes [J] is a structural gel that leaks to the outside, quickly solidifies, and then bridges any cracks that may occur during use. The sole therefore assumes an irregular form over time, depending on the load bearing areas of an individual’s foot and the stresses that are transferred into the sole. In the Eco-Top Kitchen Counter [K], the porous and random surface qualities of terracotta bring an overall sense of imperfection allied with homeliness. Irregularly placed ceramic pebbles adjacent to the hob support hot pans, whilst an aluminum tube dish drainer in a chaotic form supports wet dishes.

Exemplifying the Five Material Surface Imperfection Sources

The portfolio of product concepts contained designs that mapped onto the three phases of material-based imperfection identified in Figure 1 (i.e., material sourcing, material processing, and product use). Moreover, the product concepts echoed the five sources of material imperfection identified in the first part of the study, independently confirming their relevance to how designers think about harnessing or creating material imperfection. Figure 10 depicts the positioning of the eleven concepts under the relevant imperfection source headings, based on the participants’ product design rationale. Some of the concepts spanned multiple imperfection sources. Two of the imperfection sources were absent from the concepts. No participant conceived a product reliant on workmanship of risk, since all participants were from an industrial design training and did not have experience or skills to design and make crafts-based products. Everyday wear and tear was also absent because as has been previously noted, this source of imperfection is not designed for but instead is a consequence of use. Overall, the participants used surface imperfections to arouse interest and eliminate boredom, as well as to conceive rebellious, disobedient, and non-conformist alternative products.

Figure 10. Guide to embracing material surface imperfections in design practice.

In their explorations during the orientation phase of the concept design project, participants offered keywords—usually adjectives of sensorial properties and material meanings—to articulate their understanding of underlying concepts and contributing factors to achieving material (im)perfection. Taken collectively, the keywords define a vocabulary for designers to verbally articulate their understanding of material imperfection for the purpose of opening-up a design space (Jonson, 2005). Moreover, the keywords can be used in a conventional manner as a semantic design vision (Nagai & Noguchi, 2003), in this case for sketching product ideas based on material imperfection. In Figure 10, the keywords are clustered around the phase of the product lifecycle to which they apply. In its totality, Figure 10 provides designers with a vocabulary, entry points, and example products to spark ideas for how material surface imperfection can be pursued and achieved as a desirable product attribute.

Beyond Convention: Imperfection for Computational Composites & Digital ‘Material’

It will be appreciated that this study focused on material surface imperfections amongst what could be regarded as conventional physical material types, e.g., metals, woods, plastics, ceramics, etc. The arguments should hold true for many other classes of physical material: new and emerging hi-tech materials, DIY materials, grown biomaterials, etc., amongst which remarkable and differentiated surface qualities are common. What remains to be explored are crossovers between material surface imperfections and computational composites: materials for which physical and tactual properties are programmed or modified to change over time (Vallgårda & Sokoler, 2010).

For some time now, the computer itself has been conceptualized as a ‘material’ (Hallnäs & Redström, 2002), whilst the materiality of electrical and electronic artefacts has become an increasingly important subject amongst the HCI community (Giaccardi & Karana, 2015). One computational material that can be regarded as a material of sorts is the mass-manufactured screen. It is capable of outputting visually dynamic content that can sit seamlessly adjacent to panels of metal, wood, glass, plastic, and other conventional materials. The visual content is key here: screens can broadcast simulated material surfaces. They can broadcast surface imperfections. Furthermore, imperfections from the digital world can be layered onto those simulated material surfaces: JPEG artefacts, gross pixelation, corruption lines. These all serve to dirty or degrade the image, much like a guitar amplifier adds tonal color, grittiness, and distortion to a pure guitar signal. The potential for principles of imperfection to inform computational composite design across sensory modalities is clearly wide open.

Conclusions

Imperfection will not be to everybody’s taste. Just as a production-line McDonald’s quarter pounder or a Starbucks caramel macchiato look, taste, and feel (reasonably) the same around the world—the result of standardization as a corporate quality control—so there will always be people seeking out, or delighted to consume, a far more distinct and local variety of burger or coffee. Localized differences, we might say, make all the difference, on an experiential level. The same can be said of material imperfection: those localized material surface nuances away from the expected and commonplace define a unique and appealing character of a product.

This paper has sought to promote discussion on why and how surface imperfections in materials ought to be embraced by designers, rather than quickly brushed aside as something undesirable that should be avoided. Various entry points for bringing desirable product surface imperfection through materials have been considered, synthesizing literature, and the results of a high-profile design project exhibited at the inaugural Istanbul Design Biennial under the central event theme of imperfection proposed by Deyan Sudjic (2012).

Returning to the research questions posed in the introduction, the following concise answers can be offered.

- A material is imperfect when either its match to design specifications is poor, or its surface qualities deviate from expected norms of homogeneity.

- Material surface imperfections can occur across the product lifecycle, from sourcing of materials, materials processing, and product use. Five sources of material surface imperfection have been identified across the product lifecycle.

- Purposeful imperfection, or imperfection for a reason, is likely to be more valuable and will be appreciated by more people than ad hoc imperfection, where there has been no attempt to direct or harness the results towards an enriched user experience.

- A guide to embracing material surface imperfections in design practice (Figure 10) has been developed to assist design planning and decision-making.

The contribution of the paper has been three-fold: (i) identification and verification of five sources of material surface imperfection (inherent material properties, production effects, workmanship of risk, planned and foreseen events, everyday wear and tear); (ii) proposing a vocabulary of material imperfection relevant to design discourse; and (iii) generation and categorization of product designs to exemplify how products can benefit from material surface imperfections. These contributions are summarized in Figure 10, and taken together comprise a step forward in designing for/with imperfection.

One of the significant challenges facing designers within this subject area is one of persuasion: of designing products where imperfect material surfaces are seen by target users as a contributor to product value rather than a detractor. This is not a straightforward task, especially when transitioning from artisan practices, through batch production, to mass manufacture. If designers get the material/product combination wrong, then people’s judgement of that product’s quality, its value, and the meanings people attribute to that product can all be predominantly negative.

The five sources of surface imperfection raised through this paper are likely to have different acceptability levels depending on the sample of population targeted, the exact products involved, usage contexts, and so forth. We know this to be a fundamental aspect of material appraisal studies. To this end, the growing research field of materials experience should provide a source of robust theories and practical experiments around which imperfect material surfaces can be proposed, evaluated, and refined so as to be confident that the resulting user experience will be predominantly positive.

Acknowledgments

The authors are grateful to the IKSV/Istanbul Design Biennial Academy Program organizers for accepting the Imperfection in Product Materials project for exhibition; for Kadir Has University Faculty of Art and Design, Istanbul, for hosting the exhibition between 13.10.12 and 12.12.12; for Arçelik A.Ş. for exhibition sponsorship; to all participating students of METU ID725 Materials Experience course for their effort and enthusiasm (Merve Coşkun, Kıvılcım Çınar Okusluğ, Ayça Dündar, Betül Gürtekin, Hande Işık, Ceren Köktürk, Erçin Okursoy, Hande Öztaş, Sedef Süner, Duygu Ürün, Nur Yıldırım); and to the team of colleagues who helped prepare and host the exhibition and associated graphics (Yekta Bakırlıoğlu, Hayri Dörtdivanlıoğlu, Aslı Günay, Erçin Okursoy, Seray Türkay). The authors would also like to thank the UK Engineering and Physical Sciences Research Council (EPSRC) who provided funding for parts of the reported work through the Closed Loop Emotionally Valuable E-waste Recovery (CLEVER) project (EP/K026380/1).

References

- Alpay, E. (2013). Objectifying sound. In Proceedings of the Conference on Praxis + Poetics Research through Design (pp. 164-167). Newcastle, UK: University of Northumbria.

- Baxter, W. L., Aurisicchio, M., & Childs, P. R. N. (2016). Materials, use and contaminated interaction. Materials & Design, 90, 1218-1227.

- Boradkar, P. (2004). Skin care: The sensual surfaces of objects. In Proceedings of the International Conference on Design and Emotion [CD-ROM]. Ankara, Turkey: Middle East Technical University.

- Campbell, I., Hague, R., Şener, B., & Wormald, P. (2003). The potential for the bespoke industrial designer. The Design Journal, 6(3), 24-34.

- Candy, F., Sommerville, S., Kalviainen, M., & Oksanen, H. (2004). Temporal transformation of materials: Can designers harness the effects of time to create a contemporary aesthetic of worldliness within new products? In Proceedings of the International Conference on Design and Emotion [CD-ROM]. Ankara, Turkey: Middle East Technical University.

- Carr, C., & Gibson, C. (2016). Geographies of making: Rethinking materials and skills for volatile futures. Progress in Human Geography: An International Review of Geographical Work in the Social Sciences and Humanities, 40(3), 297-315.

- Chapman, J. (2009). Design for (emotional) durability. Design Issues, 25(4), 29-35.

- Chapman, J. (2014). Meaningful stuff: Toward longer lasting products. In E. Karana, O. Pedgley, & V. Rognoli (Eds.), Materials experience: Fundamentals of materials and design (pp. 135-143). Oxford, UK: Elsevier.

- Datschefski, E. (2001). The total beauty of sustainable products. Hove, UK: Rotovision.

- DeSilvey, C. (2006). Observed decay: Telling stories with mutable things. Journal of Material Culture, 11(3), 318-338.

- Falin, P., & Falin, P. (June 16, 2014). Making and perceiving: Exploring the degrees of engagement with the aesthetic process. Paper presented at the Conference of the Design Research Society, Umea University, Umea, Sweden.

- Fisher, T. (2004). What we touch, touches us: Materials, affects, and affordances. Design Issues, 20(4), 20-31.

- Giaccardi, E., & Karana, E. (2015). Foundations of materials experience: An approach for HCI. In Proceedings of the 33rd Conference on Human Factors in Computing Systems (pp. 2447-2456). New York, NY: ACM.

- Giaccardi, E., Karana, E., Robbins, H., & D’Olivo, P. (2014). Growing traces on objects of daily use: A product design perspective for HCI. In Proceedings of the Conference on Designing Interactive Systems (pp. 473-482). New York, NY: ACM.

- Hallnäs, L., & Redström, J. (2002). From use to presence: On the expressions and aesthetics of everyday computational things. ACM Transactions on Computer-Human Interaction, 9(2), 106-124.

- Hoadley, R. B. (2000). Understanding wood: A craftsman’s guide to wood technology. Newtown, CT: Taunton Press.

- Jonson, B. (2005). Design ideation: The conceptual sketch in the digital age. Design Studies, 26(6), 613-624.

- Juniper, A. (2003). Wabi sabi: The Japanese art of impermanence. Boston, MA: Tuttle Publishing.

- Karana, E. (2012). Characterization of ‘natural’ and ‘high-quality’ materials to improve perception of bio-plastics. Journal of Cleaner Production, 37(1), 316-325.

- Karana, E., Pedgley, O., & Rognoli, V. (2015). On materials experience. Design Issues, 31(3), 16-27.

- Karana, E., & Hekkert, P. (2010). User-material-product interrelationships in attributing meanings. International Journal of Design, 4(3), 43-52.

- Karapanos, E., Zimmerman, J., Forlizzi, J., & Martens, J. B. (2009). User experience over time: An initial framework. In Proceedings of the Conference on Human Factors in Computing Systems (pp. 729-738). New York, NY: ACM.

- Keulemans, G. (2016). The geo-cultural conditions of kintsugi. The Journal of Modern Craft, 9(1), 15-34.

- Khalaj, J., & Pedgley, O. (2014). Comparison of semantic intent and realization in product design: A study on high-end furniture impressions. International Journal of Design, 8(3), 79-96.

- Kolarevic, B., & Klinger, K. (2008). Manufacturing material effects: Rethinking design and making in architecture. Oxford, UK: Routledge.

- Koren, L. (2008). Wabi-sabi for artists, designers, poets & philosophers. Point Reyes, CA: Imperfect Publishing.

- Kotradyova, V., Teischinger, A., & Ebner, G. (2012). Aesthetic performance of different wood species: Visual interaction of human being and wood (by analyzing the colour and the texture of wood separately). Innovation in Woodworking Industry and Engineering Design, 1, 25-30.

- Lilley, D., Smalley, G., Bridgens, B., Wilson, G. T., & Balasundaram, K. (2016). Cosmetic obsolescence? User perceptions of new and artificially aged materials. Materials & Design, 101, 355-365.

- Manley, A. H. G., Lilley, D., & Hurn, K. (June 2015). Cosmetic wear and affective responses in digital products: Towards an understanding of what types of cosmetic wear cause what types of attitudinal responses from smartphone users. Paper presented at the Conference on Product Lifetime And The Environment, Nottingham Trent University, Nottingham, UK.

- McCartney, K. (2016). Perfect imperfect: The beauty of accident, age & patina. Miller Point, Australia: Murdoch Books.

- Nagai, Y., & Noguchi, H. (2003). An experimental study on the design thinking process started from difficult keywords: Modeling the thinking process of creative design. Journal of Engineering Design, 14(4), 429-437.

- Nobels, E., Ostuzzi, F., Levi, M., Rognoli, V., & Detand, J. (Nov. 25, 2015). Materials, time and emotion: How materials change in time? Paper presented at the Conference on Tangible Means – Experiential Knowledge through Materials, Kolding, Denmark.

- Norman, D. (2013). The design of everyday things. New York, NY: Basic Books.

- Odom, W., & Pierce, J. (2009). Improving with age: Designing enduring interactive products. In Proceedings of the Conference on Human Factors in Computing Systems (E.A., pp. 3793-3798). New York, NY: ACM.

- Ostuzzi, F., Salvia, G., Rognoli, V., & Levi, M. (2011). The value of imperfection in industrial product. In Proceedings of International Conference on Designing Pleasurable Products and Interfaces (pp. 361-369). Milan, Italy: Politecnico di Milano.

- Pedgley, O. (June 17, 2014). Desirable imperfection in product materials. Paper presented at the Conference of the Design Research Society, Umea University, Umea, Sweden.

- Pedgley, O. (2009). Influence of stakeholders on industrial design materials and manufacturing selection. International Journal of Design, 3(1), 1-15.

- Pedgley, O., & Şener, B. (January 2012). So, what comes next? Constructive randomness within products. Paper presented at the 8th International Conference on Design and Emotion, Central Saint Martins College of Arts and Design, London, UK.

- Pye, D. (1968). The nature and art of workmanship. London, UK: A&C Black Publishers.

- Rognoli, V., Bianchini, M., Maffei, S., & Karana, E. (2015). DIY materials. Materials and Design, 86, 692-702.

- Rognoli, V., & Karana, E. (2014). Toward a new materials aesthetic based on imperfection and graceful aging. In E. Karana, O. Pedgley, & V. Rognoli (Eds.), Materials experience: Fundamentals of materials and design (pp. 145-154). Oxford, UK: Elsevier.

- Saito, Y. (2007). Everyday aesthetics. Oxford, UK: Oxford University Press.

- Salvia, G., Ostuzzi, F., Rognoli, V., & Levi, M. (Oct. 1, 2010). The value of imperfection in sustainable design: The emotional tie with perfectible artefacts for longer lifespan. Paper presented at the Conference on Sustainability in Design, Bangalore, India.

- Schifferstein, H., & Hekkert, P. (Eds.) (2008). Product experience. Amsterdam, The Netherlands: Elsevier.

- Shashoua, Y. (2008). Conservation of plastics. Oxford, UK: Butterworth-Heinemann.

- Sudjic, D. (2012). Istanbul design biennial. Retrieved from http://1tb.iksv.org/about/biennial-theme/

- Tilley, C., Keane, W., Küchler, S., Rowlands, M., & Spyer, P. (2006). Handbook of material culture. New York, NY: Sage.

- Vallgårda, A., & Sokoler, T. (2010). A material strategy: Exploring material properties of computers. International Journal of Design, 4(3), 1-14.

- Van Hinte, E. (Ed.) (2004). Eternally yours: Time in design. Rotterdam, The Netherlands: 010.

- Van Hinte, E. (Ed.) (1997). Eternally yours: Visions on product endurance. Rotterdam, The Netherlands: 010.

- Walker, S. (1995). The environment, product aesthetics and surface. Design Issues, 11(3), 15-27.

- Woolley, M. (2003). Choreographing obsolescence-ecodesign: The pleasure/dissatisfaction cycle. In Proceedings of International Conference on Designing Pleasurable Products and Interfaces (pp. 77-81). New York, NY: ACM.