An Agenda for Research on the Relationships between Industrial Design and Performance

1 Reykjavik University, School of Business, Reykjavik, Iceland

2 Delft University of Technology, Faculty of Industrial Design Engineering, Delft, The Netherlands

This article proposes a research agenda for studying the relationships between industrial design and performance in the context of new product/service development. A review of existing research on relationships between industrial design and performance is used as a basis for identifying research opportunities and developing a research agenda. The research opportunities are derived from a number of important gaps in existing research on the relationships between industrial design and performance. These gaps include a lack of in-depth examination of the relationship between performance and industrial design emphasis, industrial design capabilities, industrial design outcomes and industrial design management. Much of the existing research is case research of a few design-conscious firms while large-scale quantitative research conducted in a broad range of firms and types of development projects is relatively scarce. Furthermore, there is a lack of comprehensive models that include moderating or mediating influences and feedback. This article provides an integrative perspective on the contribution of industrial design to performance. Such an integrative view is lacking in the literature and has caused a degree of fragmentation. Hence, the article is of particular value to researchers in this field and should contribute to increased cohesiveness in future research.

Keywords – Industrial Design, Literature Review, New Product/Service Development, Performance, Research Agenda.

Relevance to Design Practice – This article provides an integrative perspective on the contribution of industrial design to performance. Design practice can benefit from such an integrative view since it may help designers to overcome potential resistance when offering their services to and within industry.

Citation: Candi, M., & Gemser, G. (2010). An agenda for research on the relationships between industrial design and performance. International Journal of Design, 4(3), 67-77.

Received March 20, 2010; Accepted July 8, 2010; Published December 22, 2010.

Copyright: © 2010 Candi and Gemser. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: marina@ru.is.

**The authors are listed in alphabetical order, but both contributed equally to the article.

Introduction

It can be difficult for customers to assess the quality and results of industrial design services, even after making use of such services. As a result, industrial designers still meet resistance when offering their services and arguing their perspectives. In times of economic downturn, industrial design spending is frequently one of the first places where the axe falls, along with marketing and other activities deemed merely nice to have, but not essential for survival. Hence, the issue of the contribution of industrial design to business performance is particularly urgent.

Even though empirical evidence on design effectiveness is growing (e.g., Candi & Saemundsson, 2011; Chiva & Alegre, 2009; Gemser & Leenders, 2001; Hertenstein, Platt, & Veryzer, 2005), research on industrial design as an element of innovation is still relatively immature. The weaknesses of existing research in this area include weak theoretical underpinnings, fragmented definitions and operationalizations of industrial design, small sample sizes, single respondents, and testing of simple main-effect models that lack inclusion of moderating or mediating variables and feedback.

The goal of this article is to provide an integrative perspective on the contribution of industrial design to performance. Hence, the article is of particular value to researchers in this field and should contribute to increased cohesiveness in future research. A research agenda is developed, encompassing several research opportunities.

To achieve an integrative perspective, the article draws from a wide range of existing research on industrial design. This includes empirical work on the relationships between industrial design and performance (at the firm level or at the product/project level) and conceptual studies on industrial design emphasis, capabilities, outcomes and management. This research comes from a wide range of disciplinary foci, including marketing, consumer behavior, innovation and product development, management, organization and design.

The Industrial Design Construct

A specific challenge in synthesizing research on industrial design stems from inconsistencies and unclear definitions of industrial design, if definitions are offered at all. Not only in the literature but also in society at large, a profusion of ideas exist about what industrial design is (Walsh, 1996). The apparent lack of uniformity in the definition of industrial design partly reflects the different interpretations of the function of design in the new product development (NPD) process. Some authors use the term design as basically synonymous with product development (e.g., Bruce, Daly, & Kahn, 2007; Garud, Jain, & Tuertscher,2008; Hart, Service, & Baker, 1989), others view the design activity as a separate and distinct phase within the (NPD) process (e.g., Gemser & Leenders, 2001; Mukhopadhyay & Gupta, 1998; Ulrich & Eppinger, 1995). In this article, industrial design is viewed as a phase within the NPD process in which the relations between the user and the product or service take center stage, rather than the mechanics internal to the product or service.

In empirical studies on industrial design and performance, the term industrial design refers to an activity (e.g., Black & Baker 1987; Bruce & Whitehead, 1988; Candi, 2010; Candi & Saemundsson, 2011; Chiva & Alregre, 2009; Gemser & Leenders, 2001; Hertenstein, Platt, & Veryzer, 2005; Hise, O’Neal, & McNeal, 1989; Moody, 1980) or the outcome of this activity (e.g., Moody, 1984; Roy & Potter, 1990, 1993; Roy & Riedel 1997; Talke, Salomo, & Wierenga, 2009; Walsh, Roy, & Bruce, 1988). While there is no agreement on the complete spectrum of activities that can be described as industrial design, what most of the conceptualizations of industrial design as an activity share is the idea that industrial design gives “tangible form to human ideas” (Peter Lawrence, cited in: Buchanan, 2000; cf. Chiva and Alegre, 2009), with the ultimate aim of creating something that did not exist before (cf. Roy and Potter, 1990). Industrial design has been described as an activity that is primarily user-driven rather than technology-driven (e.g., Moody, 1980; Gemser, Jacobs, & Ten Cate 2006; Walsh, 1996). Hence, it is not the relations internal to a product, but the relations between the user and the product, that take center stage. Adopting this view implies that activities that relate to the technical aspects of products do not fall under industrial design. Instead, these activities generally belong under the area of engineering expertise (Moody, 1980; Walsh, 1996).

Authors that adopt a design outcome perspective, tend to use the term product design rather than industrial design (Talke et al., 2009). However, similar to research that perceives industrial design as an activity, research conceptualizing industrial design as outcomes suffers from a lack of common understanding of what industrial design outcomes actually entail. Two product aspects viewed as key outcomes of industrial design are usability and aesthetics (Gemser, Jacobs, & Ten Cate, 2006; Ulrich & Eppinger, 1995; Veryzer, 2005). Product aesthetics refers to a product’s appeal to the human senses, which, in general, is strongly intertwined with the symbolic and experiential value of a product (Creusen & Schoormans, 2005). Product usability refers to the comprehensibility of a product and its ease of operation (Creusen & Schoormans, 2005). Industrial design may also contribute to a product’s functionality or utility, and reduce manufacturing costs and customer life-cycle costs, for example through the use of shapes that are easy to manufacture or service or the use of cost-effective materials (Hertenstein et al., 2005; Roy & Potter, 1990, 1993; Roy & Riedel, 1997; Walsh et al., 1988).

Four Operationalizations of Industrial Design

As discussed above, the term industrial design means different things to different people. At least in part due to these widely varying perspectives, existing research varies in terms of the kinds of measures used for industrial design. Operationalizations of industrial design fall roughly into four categories. In the first place, some researchers use industrial design emphasis as a measure of industrial design, for example by examining the weight placed on industrial design related aspects in the NPD process (e.g., Candi, 2010; Candi & Saemundsson, 2011). Secondly, some research focuses on industrial design capabilities, including the human capabilities, time and financial resources available and exploited for industrial design (e.g., Gemser & Leenders, 2001; Roy & Potter, 1993; Swan, Kotabe, & Allred, 2005). Thirdly, there is research that focuses on the outcomes of industrial design, either as evaluated by customers (e.g., Moody, 1984) or as evaluated by design experts or peers (e.g., Hertenstein et al., 2005; Platt, Hertenstein, & Brown, 2001; Walsh et al., 1988). Finally, some researchers focus specifically on industrial design management, meaning deliberate strategies for optimizing industrial design’s contribution to performance (e.g., Chiva & Alegre, 2009; Ravasi & Lojacono, 2005; Roy & Riedel, 1997).

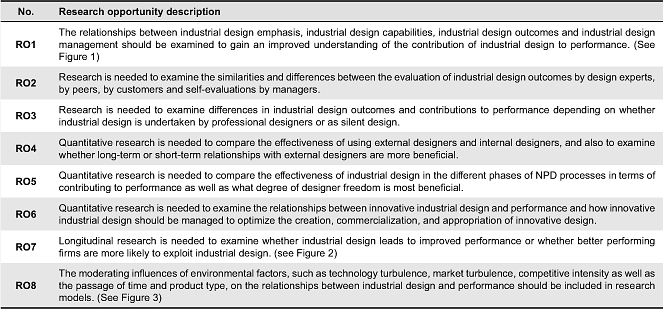

These four different operationalizations of industrial design, discussed in more detail below, lead to the first research opportunity included in this article’s research agenda.

RO1: The relationships between industrial design emphasis, industrial design capabilities, industrial design outcomes and industrial design management should be examined to gain an improved understanding of the contribution of industrial design to performance.

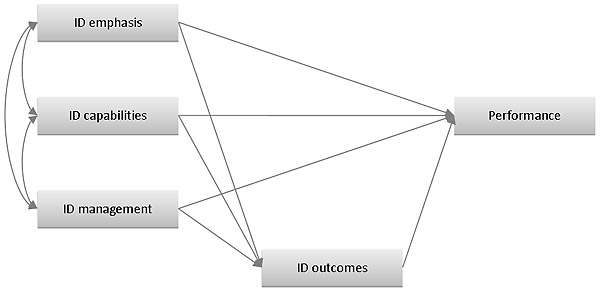

The relationships between the four operationalizations of industrial design and their relationships with performance are depicted in Figure 1.

Figure 1. The four operationalizations of industrial design and the relationships with performance suggested by existing research (ID=Industrial Design).

Following from existing research findings, Figure 1 shows the suggested relationships between the three categories of industrial design inputs, namely industrial design emphasis, capabilities and management, resulting industrial design outcomes and ultimate company or product performance. Overall, it is expected that the individual industrial design inputs will reinforce each other. Industrial design emphasis is likely to lead to better industrial design capabilities and to investments in industrial design management; better industrial design management, in turn will enhance industrial design capabilities and industrial design emphasis. Furthermore, more industrial design emphasis, better industrial design capabilities and better industrial design management are likely to lead to better industrial design outcomes. Industrial design effectiveness research that empirically investigates the relationships between two or more of the manifestations of industrial design in a systematic fashion is scarce. A notable exception is recent research by Chiva and Alegre (2009) in which the relationships between industrial design emphasis and industrial design management, respectively, and performance are studied.

Industrial Design Emphasis

To examine the relationships between industrial design and performance, researchers have adopted an operationalization that encompasses the emphasis placed on industrial design when developing new products or services. Industrial design emphasis has to do with a firm’s strategy to include or not include industrial design in its NPD activities and the degree to which industrial design is included. Subjective measures are commonly used to measure industrial design emphasis, for example industrial design influence at the senior decision-making level of a firm (Black & Baker, 1987), the degree of involvement of industrial design in the different phases of NPD (Black & Baker, 1987), or management assessments of the weight placed on industrial design in the NPD process (Candi, 2010; Candi & Saemundsson, 2011). Objective measures of industrial design emphasis include the number of specific industrial design activities performed during development projects (Hise et al., 1989).

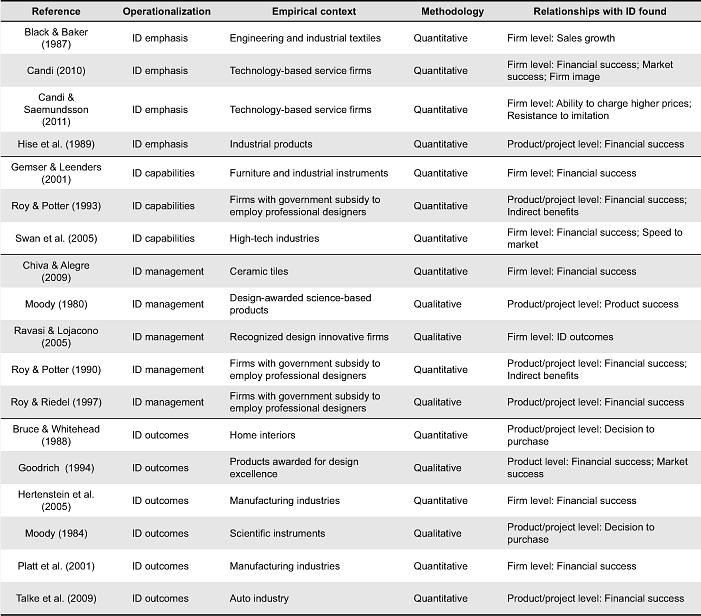

The relationships found in existing research between industrial design emphasis and performance are listed in Table 1 and include sales growth (Black & Baker, 1987), the ability to charge higher prices and resist imitation (Candi & Saemundsson, 2011), enhanced financial performance (Candi, 2010; Hise et al., 1989), market success (Candi, 2010) and improved firm image or reputation (Candi, 2010).

Table 1. Existing research on the relationship between industrial design and performance (ID=Industrial Design).

Industrial Design Capabilities

A common approach to examining the relationship between industrial design and performance is to focus on the industrial design capabilities available and exploited when developing new products or services. This may, for example, be done by counting the number of in-house designers or external design consultants used in NPD projects (Gemser and Leenders, 2001; Roy and Potter, 1993), the hours spent on design in NPD projects or in functional departments (Swan et al., 2005), or assessing and comparing industrial design budgets to total NPD expenditures (Gemser & Leenders, 2001; Swan et al., 2005).

The relationships found in existing research between industrial design capabilities and performance are listed in Table 1 and include enhanced financial performance (Gemser & Leenders, 2001; Swan et al., 2005; Roy & Potter, 1993), increased speed to market (Swan et al., 2005) and indirect benefits such as the gain of design management skills (Roy & Potter, 1993).

Industrial Design Outcomes

A number of researchers have examined the relationships between industrial design and performance by using measures of industrial design outcomes as the independent variable. Here, industrial design outcomes are defined as the exhibited industrial design characteristics of a product, service or firm. Whereas industrial design emphasis and industrial design capabilities are variables describing the amount of something, industrial design outcomes are not a measure of amount but rather a measure of goodness. To assess industrial design outcomes, two general approaches are in evidence: in some studies customer evaluations are used, while in others evaluations by industrial design experts or peers are used. Research in which customer evaluations are used can further be subdivided into two categories. First, there are those that examine how design elements such as shape, proportion, color, and configuration influence customer preferences (e.g., Veryzer & Hutchinson, 1998; Veryzer, 1993; Creusen & Schoormans, 2005; Yamamoto & Lambert, 1994; Berkowitz, 1987; Hekkert, Snelders, & van Wieringen, 2003; Meyers-Levy & Tybout, 1989; Bloch, Brunel, & Arnold, 2003). This type of research typically uses an experimental research strategy. Veryzer and Hutchinson (1998), for example, examined how product unity (congruity, or visual similarity among the elements of design) and prototypicality (the degree to which an object is representative of a category) influenced consumer preference by asking consumers to rate the visual attractiveness of different sets of line drawings of products. Overall, extant findings on consumer preferences for design elements suggest that no design guidelines that are universally applicable across different product categories and different groups of consumers can be developed (Creusen & Schoormans, 2005). Furthermore, customer preferences may not necessarily correlate with overt customer behavior (McBroom & Reed, 1992). Based on this, we decided to exclude consumer design preference research from Table 1.

The second type of research using customer evaluations to assess industrial design outcomes, examines actual customer purchase behavior instead of customer preference. This is generally done by means of surveys or interviews in which customers are asked to identify or rank factors influencing their purchase decisions (e.g., Bruce & Whitehead, 1988; Moody, 1984).

An alternative approach to customer evaluations is to have design experts or competing companies in the same industry (peers) evaluate industrial design outcomes (Goodrich, 1994; Hertenstein et al., 2005; Platt et al., 2001; Talke et al., 2009; Walsh et al., 1988). In research adopting this approach, industrial design evaluations may be collected directly, by polling experts or peers, or indirectly by examining the recipients of design awards or other forms of certification of good design such as citations in relevant indices. To test industrial design effectiveness, the performance of firms or products evaluated as exhibiting good design is compared with the performance of firms or products lacking these credentials (Hertenstein et al., 2005; Platt et al., 2001; Talke et al,. 2009; Walsh et al., 1988) or, less convincingly, by analyzing the performance of good design by itself, without explicit comparisons (Goodrich, 1994).

The relationships found in existing research between industrial design outcomes and performance are listed in Table 1 and include decision to purchase (Bruce & Whitehead, 1988; Moody, 1984), market success (Goodrich, 1994) and enhanced financial performance (Goodrich, 1994; Hertenstein et al., 2005; Platt et al., 2001; Talke et al., 2009; Walsh et al., 1988).

An important limitation of the research using industrial design outcomes is that although the use of design expert or customer evaluations to provide a measure of industrial design outcomes is possibly more valid than asking managers to evaluate their firms’ industrial design outcomes, this is still a subjective rating. Using combinations of evaluations of industrial design outcomes by various categories of peers, design experts, customers, and self-evaluations by firm management might provide more valid measures and increase understanding of the relationship between industrial design and performance. Furthermore, such research would allow important comparisons between assessments from different stakeholders. A first attempt applying such an approach can be found in Candi and Gemser (2010). In this pilot study, the aesthetic design quality of service innovations is evaluated by industrial designers (experts), actual customers, and senior management of the companies that developed these services, and these three sets of evaluations are compared.

RO2: Research is needed to examine the similarities and differences between the evaluation of industrial design outcomes by peers, by design experts, by customers and self-evaluations by managers.

Research based on any of the three operationalizations discussed so far, namely industrial design emphasis, industrial design capabilities or industrial design outcomes, has operationalized industrial design in such a fashion that it may not differentiate between work done by professional industrial designers and industrial design work performed by others (see e.g., Candi, 2010; Candi & Saemundsson, 2011; Swan et al., 2005; Talke et al., 2009). A firm may be sensitive to aspects such as aesthetics or ease of use when developing new products without actually describing this as industrial design or it may practice industrial design without employing industrial designers. Firms that are sensitive to industrial design but do not invest measurably in industrial design can nevertheless yield industrial design outcomes through the mechanism of silent design (Gorb & Dumas, 1987). Silent design refers to the process by which employees are engaged in industrial design as an adjunct to their primary roles, and usually without their activities being acknowledged as industrial design; basically non-designers doing design. Moody (1980) suggests that silent design may result in amateurish outcomes, but also acknowledges that silent design may result in successful design outcomes, in terms of being awarded design prizes, and enhanced performance. The issue of whether silent industrial design or professional industrial design is more effective may depend on the types of product characteristics examined. For example, if the contribution of industrial design to a product’s functionality and manufacturability is examined, this may result in less positive outcomes for professional design expertise compared with silent design than an examination that focuses on aesthetics and ease of use. Even though industrial designers may contribute to a product’s functionality and manufacturability, engineers may contribute more effectively due to their technical expertise, while industrial designers may contribute more effectively to the areas of aesthetics and ease of use (cf. Gemser & Leenders, 2001; Ulrich & Eppinger, 1995). This leads to the third research opportunity identified.

RO3: Research is needed to examine differences in industrial design outcomes and contributions to performance depending on whether industrial design is undertaken by professional designers or as silent design.

Industrial Design Management

A fourth stream of research examines how firms can most effectively harness the contribution of industrial design and industrial designers, or how to organize and manage industrial design to maximize industrial design outcomes and, ultimately, performance. To this end, industrial design management capabilities are needed, that is, structures and practices set up to deploy industrial design.

Most research on industrial design management is conceptual or qualitative in nature. A notable exception is the research by Chiva and Alegre (2009) who demonstrate that effective industrial design investments require effective industrial design management. However, in their research industrial design management is conceptualized in a very broad fashion, making it hard to distinguish between industrial design management and new product development management in general.

A pertinent issue in industrial design management research is whether or not companies should outsource industrial design and, when having decided to outsource industrial design, how to best manage external design expertise. In existing research, the advantages and disadvantages of hiring external designers versus having in-house designers or adopting a mixed solution using both internal and external design are examined (e.g., Bruce & Docherty, 1993; Bruce & Morris, 1994; Vanchan, 2007). For example, hiring external design consultants instead of, or in addition to, using in-house designers may help firms to profit from the knowledge these designers have acquired when working for other clients (Bruce & Docherty, 1993; Moody, 1980). On the other hand, it has also been found that adequate management of external designers is necessary but often problematic, resulting in slowing down the NPD process or even project failures (Moody, 1980; Roy & Potter, 1990). To counteract these management problems, it has been suggested that firms should strive to develop long-term relationships with external design consultants. These long-term relationships may not only result in a better understanding of a firm’s needs, but also, for example, reduce knowledge spill-over and result in virtuous learning curves (e.g., Bruce & Docherty, 1993; Bruce & Morris 1994; Jevnaker, 1998; Vanchan 2007).

Most of the existing research on the advantages and disadvantages of using internal or external industrial designers uses a qualitative and inductive research approach and does not

aim to examine quantitatively how effective design management may contribute to business performance. Further empirical research is needed to examine whether strategies such as the establishment of long-term relationships with external designers or outsourcing of industrial design are more effective for performance than short-term relationships or the use of in-house designers. This leads to the next research opportunity identified.

RO4: Quantitative research is needed to compare the effectiveness of using external designers and internal designers, and also to examine whether long-term or short-term relationships with external designers are more beneficial.

Another industrial design management issue is the degree to which industrial design and industrial designers should be integrated into the NPD process. An opinion commonly held by academics and practitioners alike is that to optimize its benefits, industrial design should be integrated not only in the latter NPD phases, when a new offering and its functions have already been defined, but also in the ideation phase (e.g., Perks, Cooper, & Jones, 2005; Ravasi & Lojacono, 2005; Veryzer & Borja de Mozota, 2005). It has been argued that integrating industrial design into the idea generation phase may result in the introduction of different and typically unfamiliar perspectives and may, thereby, lead to a higher level of creativity (Brown, 2008; Jevnaker, 1998; Ravasi & Lojacono, 2005; Veryzer & Borja de Mozota, 2005). Unfortunately, there is not much empirical evidence available that systematically examines the effectiveness of industrial design in the different phases of the NPD process. In case-study research on design award-winning science-based firms, Moody (1980) found that industrial design was used only in the latter phases of the NPD process, after the projects had been defined, to shape and configure the end results, rather than being integrated early in the NPD process. In a similar vein, Veryzer (2005) found that in the case of products based on new technological breakthroughs, technical concerns dominated the NPD process rather than industrial design, and that industrial design tended to be involved in particular towards the later stages of the NPD process. However, Veryzer (2005) did not examine performance implications.

Research suggests that there can be conflicts of perspective among industrial design and other functions involved in NPD such as marketing and manufacturing (e.g., Mukhopadhyay & Gupta, 1998; Gemser et al., 2006). Based on an in-depth study of industrial design management practices of firms well known for their innovative products and design excellence, Ravasi and Lojacono (2005) suggest that to optimize the outcome of investments in industrial design, management should make sure that industrial designers are given the resources and freedom to engage in autonomous exploration of ideas, avoiding premature interference from, for example, marketing or manufacturing. However, Ravasi and Lojacono (2005) also note that to optimize industrial design outcomes, management needs to provide clear boundaries since excessive freedom may be equally damaging. The issues discussed above point to the need to conduct systematic quantitative research to test the theories and intuitive findings of existing in-depth research about integration of industrial designers in the NPD process.

RO5: Quantitative research is needed to compare the effectiveness of industrial design in the different phases of NPD processes in terms of contributing to performance as well as what degree of designer freedom is most beneficial.

An important issue related to industrial design management is whether firms should attempt to create innovative designs or adopt a more evolutionary design approach. In most existing research and models of innovation, the innovation concept is limited to new technology (see e.g., Harmancioglu, Droge, Calantone, 2009). Innovation of a non-technological nature, including new industrial design, tends to be excluded as this is not ascribed any substantial innovative contribution. However, firms, even if not innovative in terms of technology, may still outperform competitors through innovative industrial design (Dell’Era & Verganti, 2007; Gemser & Leenders, 2001; Talke et al., 2009; Verganti, 2008). On the other hand, using a small set of design-conscious firms, Walsh et al., (1988) found tentative evidence that firms with good industrial design credentials and overall financial success were significantly more likely to have gotten design ideas from competitors, suggesting that the adoption of industrial design followership may also sometimes be a successful strategy.

The creation of industrial design innovation seems to require strong management capabilities (Verganti 2008; Ravasi & Lojacono 2005). For example, Verganti (2008) argues that truly innovative design concepts do not start from a deep analysis of user needs and requirements, but from a deep understanding of broader changes in society, culture and technology. Committed managers with good instincts are needed to select and support these design concepts that, due to their innovative character, may be unacceptable for some product developers (Jevnaker, 1998) and often take time to diffuse and achieve success because they may require profound changes in socio-cultural models (Dell’Era & Verganti, 2007).

Even when firms have succeeded in creating a truly innovative design and introducing it successfully on the market, only the best-managed firms are likely to be able to reap the rewards of being first on the market by adopting the right mix of appropriation strategies (Gemser & Wijnberg, 2001).

Much of the research discussed above is in-depth research of a few firms with recognized design performance and large-scale quantitative research is needed to gain a better understanding of industrial design innovativeness and how it should be managed for optimal performance outcomes.

RO6: Quantitative research is needed to examine the relationships between innovative industrial design and performance and how innovative industrial design should be managed to optimize the creation, commercialization, and appropriation of innovative design.

The Relationship between Industrial Design and Performance

Table 1 provides an overview of existing research that specifically addresses the relationship between industrial design and performance. The most commonly used measures of performance in this body of research are financial. These measures are often considered to be preferable to non-financial measures because they are thought to be more objective, particularly when audited financial data are used (Henard & Szymanski, 2001). However, focusing only on financial performance may be an over-simplification that can possibly yield misleading results. For example, in their study of consumer services Storey and Easingwood (1999) find that highly successful new services produce multiple benefits, not just financial benefits. They suggest that half of the value derived from service innovation is derived from what they refer to as firm benefits that include aspects such as attracting new customers, improving the loyalty of existing customers, improving firm image and creating new opportunities (cf. Storey & Kelly, 2001). Thus, an approach in which both financial and non-financial measures of performance are included seems to be advisable.

As shown in Table 1, existing research on industrial design effectiveness uses the firm or the product/project as its unit of analysis. The project or product unit of analysis seems more promising because there may be fewer intervening factors at this level, which may potentially influence the predictor-performance relationships.

Performance is generally a state that occurs at some time after the factors that influence it come into play. New products tend to take time to diffuse in a population, in particular when they are radically innovative in terms of design or technology (Dell’Era & Verganti, 2007). Therefore, research on the relationship between industrial design and performance needs to examine the two variables separated by a reasonable amount of time (cf. Hertenstein et al., 2005). In NPD literature, it is generally acknowledged that the elapsed time since a product is first introduced onto the market could affect performance results (Henard & Szymanski, 2001). In this type of research, NPD performance is measured closer to when the product was introduced (less than 36 months) or after more time has elapsed (Henard & Szymanski, 2001). However, existing industrial design effectiveness research generally does not track performance over a period of time, while such an approach may provide more insight into causal relationships and feedback effects. Performance feedback is likely to influence firms in two basic ways. Firstly, performance influences the amounts of resources available to firms. The better a firm is doing, the more resources it is likely to have at its disposal for operations and future growth, including resources available to spend on innovation and industrial design. Second, performance feedback influences organizational learning (Cyert & March, 1963), in particular the intensity and direction of innovation (Greve, 2003). In both cases, performance feedback is likely to influence how much emphasis firms put on industrial design, the means available to build industrial design capabilities and industrial design management, the quality of industrial design capabilities and industrial design outcomes, as well as the willingness to use such outcomes as a source of differentiation and competitive advantage for new products. To properly examine performance feedback and the dynamic relationships discussed above, longitudinal panel data is needed.

RO7: Longitudinal research is needed to examine whether industrial design leads to improved performance or whether better performing firms are more likely to exploit industrial design.

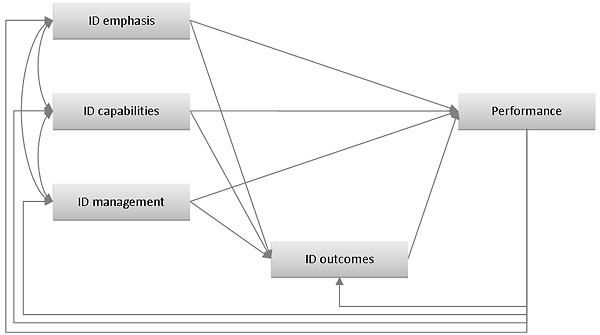

Figure 2 extends the model shown in Figure 1 to include potential performance feedback that needs to be examined to address the issue of causality.

Figure 2. The model from Figure 1 with feedback effects from performance to industrial design included (ID=Industrial Design).

To explain performance in a robust fashion, intermediate factors and interactions between factors should be taken into account (March & Sutton, 1997). Indeed, in the NPD literature, the environment and its level of stability/maturity and uncertainty/dynamism is often seen as an important factor moderating the relationship between management of NPD processes and performance (e.g., Brown & Eisenhardt, 1995; MacCormack, Verganti & Iansiti, 2001; Garud et al., 2008). Interestingly, in industrial design management research the potential moderating role of the environment seems under-studied. However, a similar contingency approach as is promoted in NPD research, involving adapting strategies to the environment, may optimize industrial design effectiveness. Swan et al. (2005) found that robust aesthetic design capabilities contribute less to performance in markets with uncertain demand conditions than in markets characterized by low demand uncertainty. In other words, in markets with high uncertainty about what will be accepted by customers, it is more difficult to design products that visually communicate and appeal to a wide range of users. Robust functional and technical design capabilities, on the other hand, were found to be beneficial for firm performance in markets characterized by high demand uncertainty rather than in more stable environments.

In addition to demand uncertainty, technology turbulence is likely to impact industrial design effectiveness. When the underlying technology of a product has leveled, leaving little scope for technological improvements, this may open the opportunity for, or may even necessitate, an increased contribution of industrial design (Candi & Saemundsson, 2011; Ulrich & Eppinger, 1995; Walsh, 1996). In case study research in the IT sector, Gemser et al. (2006) asked managers to assess the importance of appearance and usability for competitive advantage. One of their findings was that the more IT becomes standardized, the more management tends to emphasize usability and appearance in the NPD process.

It has been suggested that competitive requirements for, and potential benefits of, investments in industrial design might well be contingent on the actions of competing firms (Moultrie, Fraser & Clarkson 2002). Understanding the ways in which industrial design is utilized by competitors may indeed be important since the strategy to use industrial design as a means for differentiation may become ineffective if the diffusion rate of this strategy among competitors is relatively high, meaning that industrial design has become expected (Candi & Saemundsson, 2011; Gemser & Leenders, 2001). In other words, just like a technology, industrial design may itself become a commodity.

These findings point to the importance of including potential moderators in models intended to test the relationships between industrial design and performance, as well as the importance of tracking the contribution of industrial design to performance over time.

To identify moderating influences other than those mentioned above, explorative research could be undertaken. One of the moderating influences that might be worth studying is the type of product involved, on the spectrum from manufactured goods to services. Services are often conceptualized as having different characteristics than goods, and evaluation of services is also presumed to differ from that of goods (Henard & Szymanski, 2001). Research is needed to investigate whether these differences are reflected in the relationships between industrial design and performance. In view of the ever growing economic importance of services, more attention is needed on how industrial design can contribute to new service development. Services, although they are not manufactured objects, usually do include something that customers perceive and to which industrial design can be applied (Shostack, 1982). A credit card for example is a tangible object that is a common, although not necessary, part of credit payment services. Furthermore, although customers do not necessarily take anything with them from a service, services can create experiences (Candi, 2010).

RO8: The moderating influences of environmental factors, such as technology turbulence, market turbulence, competitive intensity, as well as the passage of time and product type, on the relationships between industrial design and performance should be included in research models.

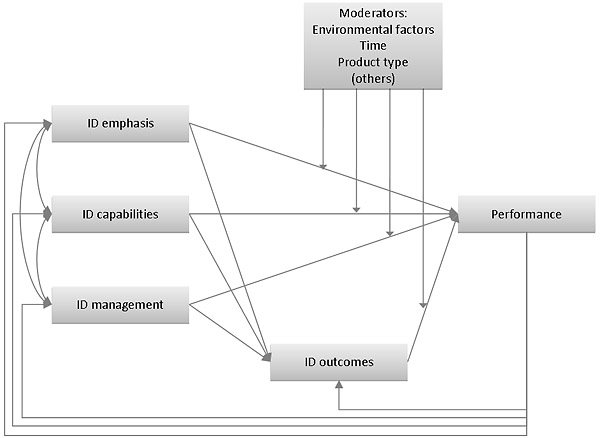

Figure 3 shows the research model including moderating influences.

Figure 3. The model from Figure 2 with moderating influences included (ID=Industrial Design).

Conclusions

The primary goal of this article is to develop a research agenda for studying the relationships between industrial design and performance in the context of new product development (NPD).

There are a number of important gaps in the existing research. These gaps include the failure to operationalize industrial design broadly enough, so as to include emphasis, capabilities, outcomes and management. Multi-faceted means of measurement and evaluation are also needed for industrial design outcomes, including not only self-assessments by managers, evaluations by customers, design experts or peers, but also combinations of these and comparisons between them. There is a lack of well-supported findings about the effectiveness of using professional industrial designers versus silent industrial designers and in-house designers versus external designers. Much of the existing industrial design research is case-based research conducted in firms recognized for design excellence or uses quantitative methodologies but with relatively small samples. Although this research provides compelling pictures of how industrial design can contribute, quantitative research using larger samples is called for. Related to this is a lack of research to address causality and performance feedback. Finally, although some research models have included moderating influences, a more comprehensive approach is still needed.

Eight specific research opportunities are developed by identifying gaps in existing research. The research opportunities are summarized in Table 2. The first three research opportunities address issues that have not been addressed adequately by existing research. The next three research opportunities (RO4-RO6) call for quantitative research to test case research findings of anecdotal propositions. The seventh research opportunity deals with the issue of causality and performance feedback. Finally, the last research opportunity addresses moderating influences.

Table 2. Research opportunities forming an agenda for research on the relationships between industrial design and performance.

The agenda developed in this article points to gaps that can be bridged by further research. Such research could contribute a better understanding of the nature and contingencies of the potential contributions of industrial design to performance. These issues are pressing ones for academics as well as practitioners and policy makers. Although understanding of industrial design as an element of NPD has been progressing based on extant research, the authors hope that this article will contribute to continued progress by encouraging further exploration of this interesting and important topic.

References

- Berkowitz, M. (1987). Product shape as a design innovation strategy. Journal of Product Innovation Management, 4(4), 274-283.

- Black, C. D., & Baker, M. J. (1987). Success through design. Design Studies, 8(4), 207-216.

- Bloch, P. H., Brunel, F. F., & Arnold, T. J. (2003). Individual differences in the centrality of visual product aesthetics: Concept and measurement. Journal of Consumer Research, 29(4), 551-565.

- Borja de Mozota, B. (2002). Design and competitive edge: A model for design management excellence in european SMEs. Design Management Journal Academic Review, 2(1), 88-104.

- Brown, S. L., & Eisenhardt, K. M. (1995). Product development: Past research, present findings, and future directions. Academy of Management Review, 20(2), 343-378.

- Brown, T. (2008). Design thinking. Harvard Business Review, 86(5), 84-92.

- Bruce, M., Daly, L., & Kahn, K. (2007). Delineating design factors that influence the global product launch process. Journal of Product Innovation Management, 24(5), 456-470.

- Bruce, M., & Docherty, C. (1993). It’s all in a relationship: A comparative study of client-design consultant relationships. Design Studies, 14(4), 402-422.

- Bruce, M., & Morris, B. (1996). Challenges and trends facing the UK design profession. Technology Analysis & Strategic Management, 8(4), 407-423.

- Bruce, M., & Morris, B. (1994). Managing external design professionals in the product development process. Technovation, 14(9), 585-599.

- Bruce, M., & Whitehead, M. (1988). Putting design into the picture: The role of product design in consumer purchase behavior. Journal of the Marketing Research Society, 30(2), 147-162.

- Buchanan, R. (2000). Good design in the digital age. AIGA Journal of Design for the Network Economy, 1(1), 1-5.

- Candi, M. (2010). Benefits of aesthetic design as an element of new service development. Journal of Product Innovation Management, 27(7), 1047-1064.

- Candi, M. (2010). Benefits of aesthetic design as an element of new service development. Journal of Product Innovation Management, 27(7). 1047-1064.

- Candi, M., & Gemser, G. (2010, October). Who should be asked? A comparison of manager, customer and designer evaluations of service aesthetic design quality. Paper presented at the 34th Annual Global Conference on Product Innovation Management, Rosen Shingle Creek, Orlando, Fl.

- Candi, M., & Saemundsson, R. J. (2011). Exploring the relationship between aesthetic design as an element of new service development and performance. Journal of Product Innovation Management. Manuscript accepted for publication in 2011.

- Chiva, R., & Alegre, J. (2009). Investment in design and firm performance: The mediating role of design management. Journal of Product Innovation Management, 26(4), 424-440.

- Creusen, M. E. H., & Schoormans, J. P. L. (2005). The different roles of product appearance in consumer choice. Journal of Product Innovation Management, 22(1), 63-81.

- Cyert, R. C., & March, J. G. (1963/1992). A behavioral theory of the firm. Malden, MA: Blackwell.

- Dell’Era, C., & Verganti, R. (2007). Strategies of innovation and imitation of product languages. Journal of Product Innovation Management, 24(6), 580-599.

- Garud, R., Jain, S., & Tuertscher, Ph. (2008). Incomplete by design and designing for incompleteness. Organization Studies, 29(3), 351-371.

- Gemser, G., Jacobs, D., & Ten Cate, R. (2006). Design and competitive advantage in technology-driven sectors: The role of usability and aesthetics in Dutch IT companies. Technology Analysis & Strategic Management, 18(5), 561-580.

- Gemser, G., & Leenders, M. A. A. M. (2001). How integrating design in the product development process impacts on company performance. The Journal of Product Innovation Management, 18(1), 28-38.

- Gemser, G., & Wijnberg, N. M. (2001). Effects of reputational sanctions and inter-firm linkages on competitive imitation of design innovations. Organization Studies, 22(4), 563-591.

- Goodrich, K. (1994). The designs of the decade: Quantifying design impact over ten years. Design Management Journal, 5(2), 47-55.

- Gorb, P., & Dumas, A. (1987). Silent design. Design Studies, 8(3), 150-156.

- Greve, H. R. (2003). Organizational learning from performance feedback. Cambridge: Cambridge University Press.

- Griffin, A., & Page, A. L. (1996). PDMA success measurement project: Recommended measures for product development success and failure. Journal of Product Innovation Management, 13(6), 478-496.

- Harmancioglu, N., Droge, C., & Calantone, R. J. (2009).Theoretical lenses on domain definitions in innovation research. European Journal of Marketing, 43(1/2), 229-263.

- Hart, S. J., Service, L. M., & Baker, M. J. (1989). Design orientation and market success. Design Studies, 10(2), 103-111.

- Hekkert, P., Snelders, D., & van Wieringen, P. C. W. (2003). Most advanced, yet acceptable: Typicality and novelty as joint predictors of aesthetic preference in industrial design. British Journal of Psychology, 94(1), 111-124.

- Henard, D., & Szymanski, D. M. (2001). Why some new products are more successful than others. Journal of Marketing Research, 38(3), 362-375.

- Hertenstein, J. H., Platt, M. B., & Veryzer, R. W. (2005). The impact of industrial design effectiveness on corporate financial performance. Journal of Product Innovation Management, 22(1), 3-21.

- Hise, R. T., O’Neal, L., McNeal, J. U., & Parasuraman, A. (1989). The effect of product design activities on commercial success levels of new industrial products. Journal of Product Innovation Management, 6(1), 43-50.

- Jevnaker, B. H. (1998). Absorbing or creating design ability: Hag, hamax and tomra. In M. Bruce & B. H. Jevnaker (Eds), Management of design alliances (pp. 107-133). New York: John Wiley & Sons,

- MacCormack, A., Verganti, R., & Iansiti, M. (2001). Developing products on “Internet Time”: The anatomy of a flexible development process. Management Science, 47(1), 133-150.

- March, J. G., & Sutton, R. I. (1997). Organizational performance as a dependent variable. Organization Science, 8(6), 697-706.

- McBroom, W. H., & Reed, F. W. (1992). Toward a reconceptualization of attitude-behavior consistency. Social Psychology Quarterly, 55(2), 205-216

- Meyers-Levy, J., & Tybout, A. M. (1989). Schema congruity as a basis for product evaluation. Journal of Consumer Research, 16(1), 39-54.

- Moody, S. (1980). The role of industrial design in technological innovation. Design Studies, 1(6), 329-339.

- Moody, S. (1984). The role of industrial design in the development of new science-based products. In R. Langdon (Ed.), Design policy: Design and industry. London: The Design Council.

- Moultrie, J., Clarkson, P. J., & Probert, D. R. (2007). Development of a design audit tool. Journal of Product Innovation Management, 24(4), 335-368.

- Moultrie, J., Fraser, P., & Clarkson, P. J. (2002, June). The innovation-styling spectrum: A framework for the valuation of industrial design involvement in new product development. Paper presented at 9th International Product Development Management Conference. Sophia Antipolis, France.

- Mukhopadhyay, S. K., & Gupta, A. V. (1998) Interfaces for resolving marketing, manufacturing and design conflicts: A conceptual framework. European Journal of Marketing, 32(1/2), 101-124.

- Perks, H., Cooper, R., & Jones, C. (2005). Characterizing the role of design in new product development: An empirically derived taxonomy. The Journal of Product Innovation Management, 22(2), 111-127.

- Platt, M. B., Hertenstein, J. H., & Brown, D. R. (2001). Valuing design: Enhancing corporate performance through design effectiveness. Design Management Journal, 12(3), 10-19.

- Ravasi, D., & Lojacono, G. (2005). Managing design and designers for strategic renewal. Long Range Planning, 38(1), 51-77.

- Roy, R., & Potter, S. (1990) Managing design projects in small and medium-sized firms. Technology Analysis & Strategic Management, 2(3), 321-336.

- Roy, R., & Potter, S. (1993). The commercial impacts of investment in design. Design Studies, 14(2), 171-193.

- Roy, R., & Riedel, J. C. K. H. (1997). Design and innovation in successful product competition. Technovation, 17(10), 537-548.

- Shostack, L. (1982). How to design a service. European Journal of Marketing, 16(1), 49-63.

- Smith, R. E., & Swinyard, W. R. (1983). Attitude-behavior consistency: The impact of product trial versus advertising. Journal of Marketing Research, 20(3), 257-267.

- Storey, C. D., & Easingwood, C. J. (1999). Types of new product performance: Evidence from the consumer financial services sector. Journal of Business Research, 46(2), 193-203.

- Storey, C., & Kelly, D. T. (2001). Measuring the performance of new service development activities: An explorative study. Service Industries Journal, 21(2), 71-90.

- Swan, K. S., Kotabe, M., & Allred, B. B. (2005). Exploring robust design capabilities: Their role in creating global products, and their relationship to firm performance. Journal of Product Innovation Management, 22(2), 144-164.

- Talke, K., Salomo, S., Wierenga, J. E., & Lutz, A., (2009). What about design newness? Investigating the relevance of a reglected dimension of product innovativeness. The Journal of Product Innovation Management, 26(6), 601-615.

- Ulrich, K. T., & Eppinger, S. D. (1995). Product design and development. New York: McGraw-Hill.

- Vanchan, V. (2007). Communication and relationships between industrial design firms and their customers. The industrial geographer, 4(2), 28-46.

- Verganti, R. (2008). Design, meanings, and radical innovation: A metamodel and a research agenda. Journal of Product Innovation Management, 25(5), 436-456.

- Veryzer, R. W. (1993). Aesthetic response and the influence of design principles on product preferences. Advances in Consumer research, 20(1), 224-229

- Veryzer, R. W., & Borja de Mozota, B. (2005). The impact of user-oriented design on new product development: An examination of fundamental relationships. Journal of Product Innovation Management, 22(2), 128-143.

- Veryzer, R. W., & Hutchinson, J. W. (1998). The influence of unity and prototypicality on aesthetic responses to new product designs. Journal of Consumer Research, 24(4), 374-394.

- Veryzer, R. W. (2005). The roles of marketing and industrial design in discontinuous new product development. Journal of Product Innovation Management, 22(1), 22-41

- Wall, T. D., Michie, J., Patterson, M., Wood, S. J., Sheehan, M., Clegg, C. W., & West, M. A. (2004). On the validity of subjective measures of company performance. Personnel Psychology, 57(1), 95-118.

- Walsh, V., Roy, R., & Bruce, M. (1988). Competitive by design. Journal of Marketing Management, 4(2), 201-216.

- Walsh, V. (1996). Design, innovation and the boundaries of the firm. Research Policy, 25(4), 509-529.

- Yamamoto, M., & Lambert, D. R. (1994). The impact of product aesthetics on the evaluation of industrial products. Journal of Product Innovation Management, 11(4), 309-324.