A Tacit Understanding: The Designer’s Role in Capturing and Passing on the Skilled Knowledge of Master Craftsmen

Art & Design Research Centre, Sheffield Hallam University, Sheffield, UK

Over the past 7 years we have investigated how craft skills may be elicited and embodied in multimedia learning resources. This led to an understanding of the principles of eliciting and transmitting such knowledge (Wood, 2006). The most recent project has developed and evaluated a practical system for designers who wish to undertake this work. By engaging with master craftsmen, expert learners and novices to create and use a web-based learning resource it was found that well-motivated learners, working in physical isolation but supported by an online community, could acquire difficult new skills and use them in creative ways. The paper also outlines key theory from the preceding research to explain how this is achieved. It indicates how the focus of the research has moved from the production of highly structured conventional multimedia materials to the use of web 2.0 resources that invite participation and exchange by learners.

Keywords – Learning, Multimedia, Tacit Knowledge, Craft, Expertise.

Relevance to Design Practice – This paper describes research-led methods for the design of learning materials including approaches to both elicitation and transmission of the skilled knowledge of experts.

Citation: Wood, N., Rust, C., & Horne, G. (2009). A tacit understanding: The designer's role in capturing and passing on the skilled knowledge of master craftsmen. International Journal of Design, 3(3), 65-78.

Received February 18, 2009; Accepted October 15, 2009; Published December 28, 2009.

Copyright: © 2009 Wood, Rust, and Horne. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: nicola@nicolawood.net.

Introduction

In this paper we describe the process and outcomes of a research project that brings a designerly approach to the problem of capturing and passing on the skilled knowledge of master craftsmen using interactive digital media. This is relevant to situations where traditional craft apprenticeships are not be available and many of the people who wish to acquire these skills fall outside traditional expectations. For example they may be older, more independent and focused on personal creative goals rather than employment.

This might be seen as a problem to be investigated by educators, however, when we commenced this research, there was relatively little literature that showed education theorists engaging with the problems of learning this kind of practical, tacit knowledge with these new media.

Apart from understanding how learners might be supported, there is also a need to understand what must be learned. Currently there is a dearth in the scholarly literature that provides such understanding for the huge variety of craft practices around us. A number of projects have set out to record the working practices of craftspeople, often on video, but these do not provide any kind of organised framework for learning, nor do they appear to result in any specific insights that would aid learners.

Nicola Wood, as a multimedia designer, has undertaken an extensive programme of research over more than 7 years to explore the methods that designers might adopt to elicit such knowledge and embed it into materials that would support skills learning. The methods of this research have a passing similarity to action research that might be undertaken to explore educational strategies. However there are some fundamental differences, especially in contrast to Kurt Lewin’s “action research spiral” involving cycles of planning, action and fact-finding about the results of the action (Smith, 2001).

First, taking Rittel and Webber’s (1984) description of design problems as “wicked problems”, our approach assumes that we will not have defined our problem until we have also developed our solution. The research follows particular principles of technique and rigour in its practices, as will be seen below, but it remains open about intention and focus. This focus, and the anticipated outcomes, has shifted repeatedly as issues have emerged in practice of making/exploring. Rittel and Webber describe “an argumentative process in the course of which an image of the problem and of the solution emerges gradually among the participants, as a product of incessant judgment, subjected to critical argument” (p. 138).

Second, the artefacts of the research, its designed materials and processes, have had a provisional quality, intended to aid exploration of the problem rather than test possible solutions to it. Our approach has followed the example outlined by Ehn and Kyng (1991) who pioneered the use of mockups as tools for engaging with stakeholders rather than prototypes to be evaluated.

Third, the research has engaged simultaneously with the two problems of what is to be learned and how it will be learned. It brings together master craftsmen, learners and designer in hybrid activities that provide an arena for generating understanding of skilled practice, embodied implicitly in learning materials rather than stated explicitly in formal conclusions.

The research focused on the skills of traditional folding knife makers in Sheffield, once a significant part of the city’s famous metalworking industries but now declined to just a few master craftsmen. In this paper we write about case studies we undertook with two of these craftsmen, a blade grinder and a folding knife maker, to demonstrate the tacit nature of such craft skill and reveal the methods we used for elicitation and interpretation. We describe how an expert learner worked alongside the craftsmen, observed by the designer, and then through experimental making and collaboration with the designer prototype learning materials were generated. The materials were tested and developed into an online resource using a small group of learners who come from a new generation of creative metalworkers whose interests lie in adapting traditional skills to new craft practices. As a result we were able to demonstrate that the principles for craft transmission developed in previous research could be applied to a specific example of craft knowledge with useful results for the learners. We also developed a more robust methodology for the elicitation and design development methods needed for this form of design practice.

The research described in this paper was a two year inquiry funded by the UK Arts and Humanities Research Council (AHRC), following on from earlier AHRC doctoral research which developed the methods used and evaluated here. As well as evaluating the principle that multimedia materials developed in this way can be beneficial to craft learners, there was an unexpected outcome; that well-motivated learners, with access to an online peer support network, can use these learning materials to advance as craftsmen with no traditional instruction.. This was not anticipated because the working assumption of the research has been that multimedia materials would always be a complement to traditional forms of instruction.

While the subject of study is traditional craft skills, the research could have wider applications in both contemporary craft practice and other practices involving skills with a significant element of tacit knowledge such as healthcare, performance, catering, construction and sport. It potentially has applications in any area where tacit understanding needs to be developed as it leads people to attend to the tasks and activities of professional work not purely as a means to a practical end, but as bridges to a richer understanding of the practice. The research may be of interest to educators in art and design and beyond, in those interested in the development and sustainability of the crafts and researchers concerned with the theory of tacit or experiential knowledge. Future research is planned to investigate applications in more formal settings.

Methods

Earlier work evolved a set of principles for the design of multimedia learning materials (Wood & Rust, 2003) that provided for cycles of learning, initially supported by explicit instructions but becoming progressively more reflective as the learner’s confidence and critical ability develops. The next stage of work moved on to develop techniques for elicitation of expert knowledge from craft masters (Wood, 2006). This involved close observation, involvement of learners at different levels of development and the use of “mockup” learning materials.

The skills involved in undertaking such craft practice involve a high degree of tacit knowledge which is internalised and frequently difficult for the craft expert to articulate. There is also a natural reticence of skilled practitioners to talk about their practice. Nicola Wood has regularly encountered such reserve in her work with a wide range of craft practitioners and it is has been recorded in other areas of research involving knowledge elicitation (e.g., Shadbolt & Milton, 1999; Edwards, 2003). When asked to talk about complex matters, skilled practitioners have a tendency to give brief responses that over simplify and give minimal insight into the situation, or even differ from observed practice, presenting a barrier to knowledge elicitation.

One of the first craftsmen we worked with was very sensitive to questions regarding his knowledge. During formal elicitation he was often dismissive or defensive. When the researcher uncovered an area of tacit knowledge for which he had constructed theory that was not borne out in practice, he was reluctant to reconsider his theory. In that particular case the personal relationship between researcher and craftsman allowed the researcher (Nicola Wood) to persuade the craftsman to re-evaluate his theory by watching a video of himself. With most other people, the researcher felt it would be unproductive to be so challenging and there is also evidence that a video might fail to make an impression. Edwards (2003) related that “it was not uncommon for a worker to deny vigorously that they ever carried out a task in a certain way, even after they had seen themselves doing it on the video!” (p. 6).

As the previous stages of this research developed it was seen that the presence of learners in the elicitation process often had a valuable effect in helping to identify such gaps in understanding, especially where the learner had developed some self-confidence in their relationship with the craft master. It was also noted that previous research had investigated areas of craft skill in woodworking where the researcher, Nicola Wood, has a considerable amount of practical knowledge of the materials and general practices involved. To allow the methods to be applied to a wider range of practices that were beyond the expertise of the designer/researcher, and ensure the presence of a confident learner, the most recent research employed an “expert learner”, Grace Horne who has wide experience of craft metalwork, as an intermediary between the craft master and the designer.

The project that is reported on in this paper demonstrated that the expert learner had the ability to learn new skills with minimal instruction. Then, as the knowledge was recently acquired and the expert learner was consciously engaged with the elicitation process, she was able to rapidly adapt her understanding of it to improve transmission to the learners.

A key aspect of this process was the expert learner’s interaction with the designer and the developing learning resource. Through a process of video recording and summarising events using drawings and flow charts, the designer/researcher assisted with articulation of the knowledge and developed interpretation suitable for transmitting the knowledge. By using this material to mediate interactions between the expert learner and novice learners, the designer/researcher was able to facilitate reciprocal reflection (Schön, 1987, p. 104) between the two and develop the learning resource.

The other important feature of the methods is the observational techniques and experience developed by the designer/researcher over several previous cycles of inquiry into a variety of craft practices and learning activities. Video recording is a central feature of this work and depends on careful selection and use of equipment and techniques to ensure that recording does not intrude on the activity but does result in a useful record, often in locations that are highly compromised by bad lighting, difficult sight lines and shifting objects of attention. This problem and the approaches taken have been discussed in detail by Wood (2006, p. 21).

Video was adopted originally as a potential medium for instruction. Although video material has not proven useful for this purpose, drawings and diagrams being more successful with learners (Wood, 2006, p. 53), it has been an invaluable resource for capturing subtle and complex aspects of the activities, to be uncovered by the participants in subsequent reflective analysis. The term “video-ethnography” is sometimes used to describe this combination of participant-observation and collaborative video analysis, especially in an industrial setting, for example Nick Leon (2005) provides some interesting practical examples. While that description is useful in drawing attention to that character of the work and the descriptive material that results from it, as seen below, we feel the term has too many associations with other social research practices to be used reliably in this case.

Practical Work

Pilot Study: Blade Grinder

At the start of the project a pilot study was used to deal with a number of problems. It was necessary to develop the partnership between the designer/researcher (Nicola Wood) and the expert leaner (Grace Horne) and to gain experience with the particular recording equipment/techniques and the environments that would be encountered. The pilot study also allowed the role of the expert learner to be explored and developed. The context for the pilot study, traditional blade grinding, is relevant to the main topic of custom knife making but not a central part of the craft skills being examined.

A blade grinder puts the bevel onto knife blades, thinning them towards the cutting edge which will be sharpened only once the knife is complete. Before industrialisation, blades were roughly shaped when they were forged, but nowadays they are cut or stamped out of sheet steel leaving more of a task for the grinder.

Our participant craftsman had begun working as an apprentice in 1957 when he was fifteen years old, apprenticed to his father who was the ‘Gaffer’ in charge of a large industrial workshop. At that time the emphasis of the work was moving towards more mechanised approaches but, in his spare time, he was allowed on the grinding wheels and would hand grind. After three years he set up a grinding workshop on his own and continues hand grinding a wide variety of tools using large, circular stones which run in water, one of few remaining craftsmen practicing this trade in the city.

Figure 1 (left to right): Expert learner grinding, the craftsman’s workshop, blades from the manufacturer at the rear, and ground blades at the front.

As a person the craftsman was in many ways a typical, tough, blunt working man, but he enjoyed conversation, talking about his boat where he spent most weekends restoring the engine. He made no claims to having any experience of teaching, but he was a remarkably patient, sensitive tutor and was keen to encourage the expert learner and praise her work. This was in contrast to other experts encountered during the research who have been much less open and communicative.

The expert learner had four one day training sessions, each video-recorded in its entirety by the designer. After each session the designer would process the video by watching it through and writing event logs to provide a summary of the observed actions and dialogue (Wood, 2006, p. 21), then select a range of issues illustrated by video clips where necessary. These were used to stimulate discussion with the expert learner about what needed to be achieved during the next session.

The craftsman’s teaching method was to demonstrate, then for a short while to offer guidance whilst the expert learner practiced, then to leave her to experiment whilst remaining nearby so she could ask for help when needed. Whilst the craftsman struggled to explain what he was doing during the demonstrations, once the expert learner had gained some initial experience she was able to question and draw from him the help she needed. For example, when the craftsman was demonstrating grinding for the very first time he did not attempt any sort of description, simply saying, “You’ve just got to …” and then demonstrating. When the expert learner asked him how he knew that he was putting the blade on the stone at the correct angle, he floundered for words then said, “You just feel it.” He then started to grind the other side of the blade to see if he could come up with something more descriptive, but again all he could say was that he could feel that it was correct.

The craftsman found a means to communicate once the expert learner had her first short experience of grinding. He watched her quite closely, had a look at the blade she had been grinding and they agreed that she needed to be holding it at a flatter angle. Then, by miming the action, he suggested that to feel the angle at which the blade was on the stone she should use a small rocking movement of her hand holding the blade. The expert learner conferred back to him, “If I do that a little bit I’ll be able to feel where I am?” and she mimicked the action with her hand. He agreed and she proceeded to experiment with the technique.

This activity highlighted the difficulty an expert can have articulating his knowledge; explaining it to an observer. During that first demonstration the expert learner was aware that her problem would be to know the angle at which the blade should meet the stone and initially the craftsman could not help other than to say that he could just feel it. However, following this questioning and through observing her actions, the craftsman was able to suggest a rocking movement that would help her feel how the blade was sitting. Again, he had few words to describe it, but through the experience she had gained, his action was enough to give the expert learner a feel for what she should do.

She was later able to give a better description of the rocking motion to the designer as subtly feeling where the front edge was, feeling where the back edge was and then settling for an angle between the two. The identification of this movement we will discuss further in the theory section of this paper. It is what we will refer to as a ‘bridge’; a key piece of explicit knowledge that can help the learner access the tacit knowledge of the craftsman.

During the training period the expert learner was able to gain significant experience, had useful feedback from the craftsman, and gained a good understanding of the tools and techniques involved. Although he could initially do little more than demonstrate, through observing the expert learner’s attempts to imitate his practice and discussion with her, the craftsman was able to develop a means of communication to help the expert learner gain the skill.

As well as the practical benefits anticipated from this pilot study, it reinforced our understanding of some important aspects of craft or tacit learning, exemplified by the blade grinder’s very effective method of instruction. This is developed in the discussion section below with particular reference to the theories of Polanyi, Schön and Argyris.

Main Study: Folding Knife Maker

For the main body of the research the expert learner worked with a traditional folding knife maker, again observed and recorded by the multimedia designer. However this craftsman was reluctant to allow the expert learner to question him or to engage in any experimentation, so she followed-up her experience with experimental making in the university workshops, supported by material from the designer’s observation.

This material was gradually developed by the designer into a learning resource which was tested and developed with a series of learners. This allowed the expert learner to develop her skill while retaining an explicit understanding as well as the necessary internalised ability, as she shared it with other, less skilled, craft practitioners, observed by the designer who used the interactions to update the resource. The learning materials are now online (Wood, 2009) and have been successfully been used by some independent learners without the direct support of the expert learner or the designer.

The Craft and Craftsman

Folding knife making in Sheffield has now largely become a semi-industrialised process constructing knives from pre-stamped parts. As stamping the parts is an inaccurate process and making the internal mechanism run smoothly requires accuracy, some considerable customisation is still needed to make the knives. This aspect is of particular interest to the new generation of knife makers who are focused on producing very individual custom knives where the integration of mechanism and form is fundamental to the success of their design and subtly different for each product. The trend in this field is for craftsmen, especially in the USA, to produce individual beautifully made knives that command high prices. By contrast the industrial tradition in Sheffield has focused on relatively cheap standard products that, arguably, do not justify the level of craftsmanship employed. One of the main aims of this research has been to assist with the transmission of skills to a new generation interested in more innovative or artistic work.

The participant craftsman began knife making as apprentice to his uncle, in 1957 when he was fifteen years old and at that time his uncle had ten workers. He worked there for ten years before moving to another folding knife manufacturers doing more specialised work on traditional open razors. When his uncle died in 1975, he took over the business with his brother and continued making working folding knives with two or three men that had worked with his uncle. In 1980, he started working on his own, in the manner that he still does today.

Figure 2 (left to right): The craftsman, parts of a traditional folding knife, set of “Ettrick” folding knives made by the expert learner under the craftsman’s guidance.

As a person, he was another tough, blunt working man, but was much less inclined to chat than the blade grinder, even though the expert learner had known him for some time. She had worked with the craftsman from time to time over the last few years, but working on large batches of knives in random small parts of the production process. For this project he agreed to guide her through the complete process step-by-step but it emerged that his aim was that she should end up with a perfect knife rather than having learned the skills.

Elicitation and Transmission

Again, the learning took place over a series of one day sessions, with each one being video recorded and event logs written between times. The craftsman worked on an identical knife to the expert learner, demonstrating and getting her to imitate until she did so to his satisfaction, then moving onto the next step.

With the craftsman’s focus being to get the knife made successfully rather than giving the expert learner an understanding of the process, he left little room for any sort of experimentation or questioning by the expert learner. As previously observed in similar circumstances (Wood & Rust, 2003; Wood, 2006, p. 63) he would frequently take the expert learner’s knife and complete operations himself, or do a little more to it after she had finished, to ensure it was a good knife when completed. Whilst this did not suit the expert learners’ needs in our case, a traditional apprentice would have sufficient opportunity to repeat the making process, so over time could gain the necessary skill in this manner.

The craftsman was also not keen to share any problem solving with the expert learner and did not wish to be video-recorded undertaking such work. For example, at one stage the craftsman had made an error with his own knife. The expert learner was keen to see how he solved the problem, but he sent her to do more work on her own knife whilst undertaking the repair where she could not watch. When he returned, she questioned him about it, but had to be quite persistent to get an answer. When he did show her, he deliberately turned his back on the camera and when the designer moved position, he hid the knife. The expert learner then asked him directly if he would show the camera “the little trick” but he refused and quite firmly told her to return to her work.

To break free of the constraints of working with the craftsman, the expert learner decided to work on her own, converting the process to one suitable for smaller scale production largely using hand tools. Firstly she spent some time making knives in the University’s workshop from parts supplied by the craftsman, then she developed her knowledge by guiding a variety of learners through the process. Throughout this period the expert learner worked closely with the designer, using a developing learning resource as a means of recording and testing her understanding of the skills.

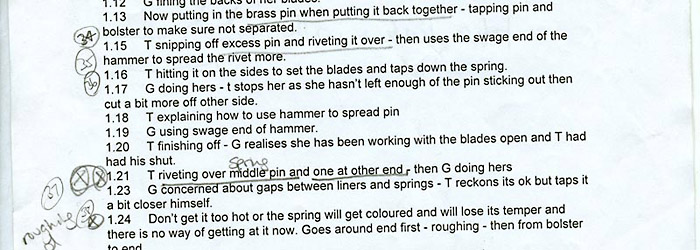

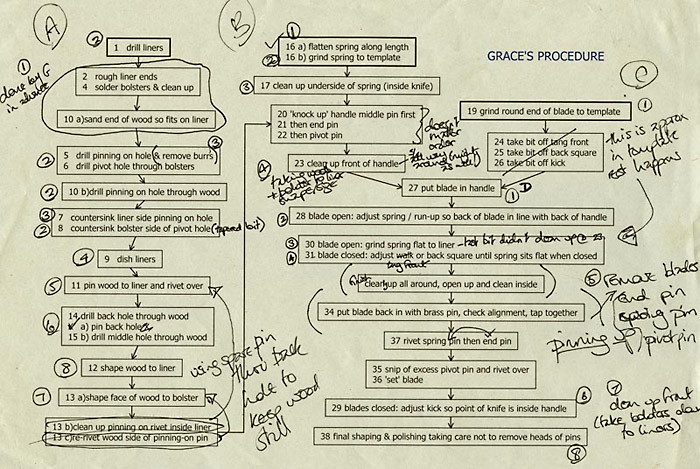

As a starting point, the designer used the video event logs (Figure 3) to produce a simple flow chart of observations of the craftsman’s procedure (Figure 4) and the expert learner made a knife working through the flow chart, adjusting it to be more streamlined for making individual knives and changing some processes for use with hand tools. Then the expert learner made a second knife following the new procedure to check for problems or inconsistencies.

Figure 3. A sample from video event log showing annotations identifying procedure.

Figure 4. The flow chart annotated by the designer whilst working with the expert learner.

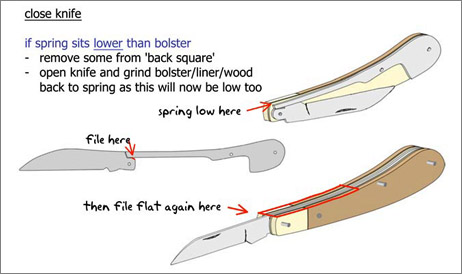

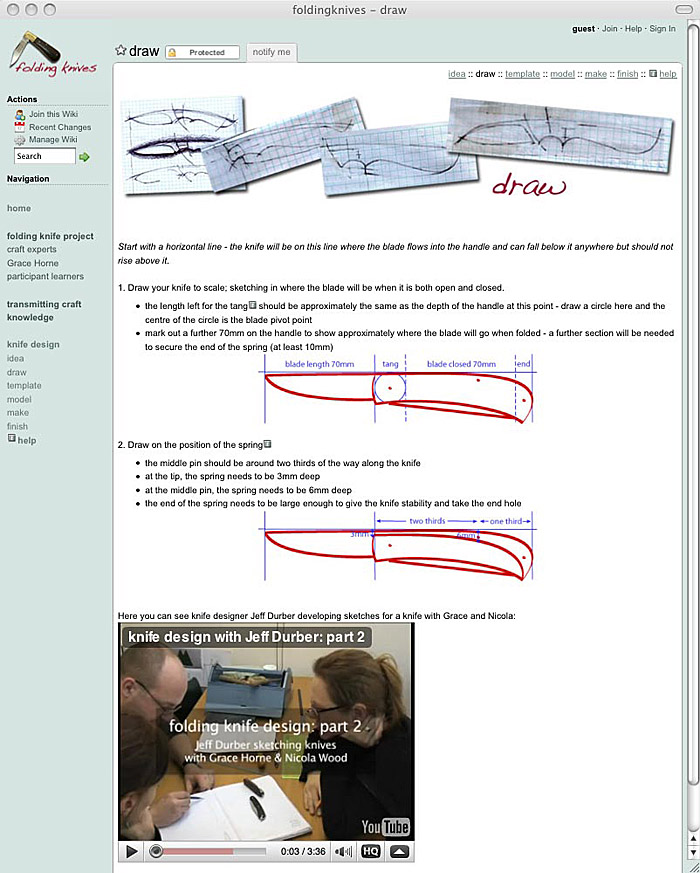

The designer then used the flow charts to make a set of worksheets (Figure 5), illustrating the procedure with simple line drawings that in previous research (Wood, 2006, p. 49) had proved most effective and popular with learners. These were then tested and developed by the expert learner using them as a basis for teaching a variety of more novice learners.

Figure 5. A sample worksheet from first stage of interpretation.

At this stage interpretation had only been developed for constructing a knife from given parts, which was a useful part of the learning process but lacked any significant creative input which the learners desired. In response to this, further interviews and observations were carried out with another expert practitioner, Jeff Durber. Durber was formerly part of a professional knife making partnership (Featherstone & Durber), producing very high quality folding knives that were sold through events such as Chelsea Craft Fair and through galleries. He had ceased knife making in 2001 for personal reasons and currently teaches Metalwork & Jewellery at Sheffield Hallam University. He took the expert learner through the process he used to design knives from first principles; from sketching to making prototypes to finishing the knife.

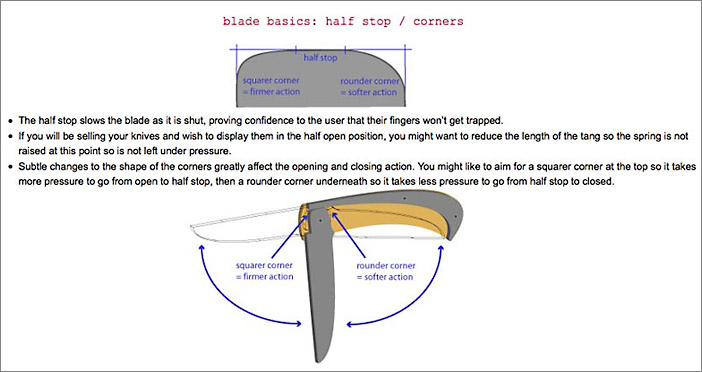

Through a series of short workshop-based sessions the expert learner quickly gained a good understanding of the process. Like the blade grinder described above, Durber was quick to engage in reciprocal reflection and the expert learner was able to pick up on subtle parts of his practice and question him until she had gained an understanding. For example, when he was cutting a template for a knife blade from plastic, the expert learner noticed the shape of the part inside the knife (the round end) was not symmetrical. When she first pointed this out, Durber was not aware of what he had done, but as they sketched together to discuss the subtleties of the shape he realised the importance of what he had done and went on to discuss how the shape of this part of the blade effects the feel of the knife as it is opened and shut. The expert learner then explained this to the designer who produced interpretation for the learning materials (Figure 6). This is another example of a bridging moment (discussed in the theory section, below) where a key piece of explicit knowledge is uncovered that can help transmission of knowledge between novice and expert.

Figure 6. Interpretation from the learning resource; an example of a bridge to understanding how the ‘round end’ of blade effects the feel of the knife as it is opened and shut.

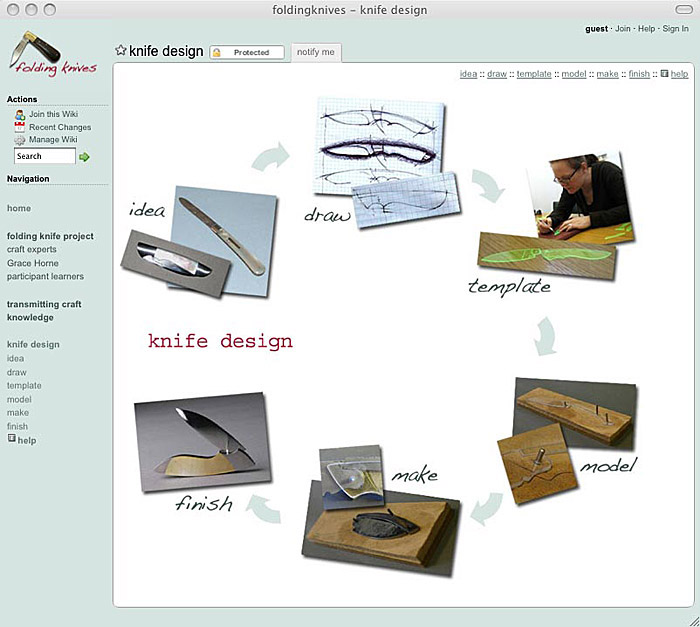

The interpretation was set out in digital form using a private wiki1, structured according to the framework developed during the designer’s previous , described in full in Wood and Rust (2003) and Wood (2006, p. 43). This supports students through three phases of learning; the first is a passive phase where they gain an overview of the task in hand, often supplied by video, the second is an active phase where they are guided step-by-step through the task in hand using the ‘bridges’ developed by the designer and expert learner, often in diagram form, and the third is a reflective phase where they are encouraged to assess their outcome and repeat the process to improve their skills. Examples of pages from the resource can be seen in appendix 1.

To test and develop the on-line resource a group of learners was recruited from an internet forum British Blades (http://www.britishblades.com/forums/) which acts as a focal point for British knife makers. The initial group were given some guidance by being asked to source images of knives they liked and produce sketches before being visited by the designer and expert learner who guided them through the initial prototyping of their first knife. They were then left to finish the knife in their own time with the wiki for backup supported by email correspondence with if required. Subsequent learners have been added who have entirely made knives using the online resource.

The quality of work produced by the learners, and the progress they had made, was evaluated by two knife makers — the expert learner and Jeff Durber, who had developed his practice of making custom folding knives following formal training in metalwork and jewellery. Both were experienced in teaching and assessing degree-level craft students in metalwork and were supported by a senior colleague with extensive experience of teaching jewellers and silversmiths. This group confirmed that the learners had produced knives of original design and good functional and visual quality to a standard that would not be expected of individuals working alone without instruction or a peer group doing similar work, as would be expected in most kinds of craft learning.

Theoretical Framework

A great part of a craft practitioner’s knowledge is internalised, as demonstrated by the difficulty that the master blade grinder experienced in articulating his knowledge in the pilot study. The theory governing such a craft practitioners’ actions is often only known through their undertaking those actions (Polanyi, 1966, p. 17). On a purely functional level, tacit knowledge might be seen as offering advantage to the craft practitioner by reducing cognitive load, freeing the mind from one level of a task to enable thought to be directed at another.

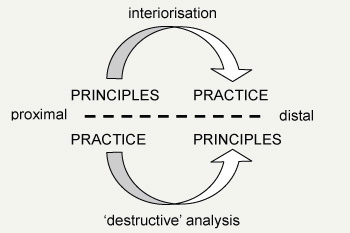

To explain tacit knowing at a deeper level, Polanyi (ibid p. 10) proposed that it had two terms: the proximal (that situated nearer to oneself) and the distal (that situated further from oneself). He described the functional relationship between these terms as knowing the proximal only through what it tells us about the distal. Hence practitioners only know the tacit principles that govern their practice through their effects whilst in the act of undertaking that practice. Polanyi (ibid p. 17) further described the phenomenal structure of tacit knowing as attending from the proximal to the distal. The practitioner attends to the distal, the result that they are working for. They do this from their tacit principles and those principles can only be learned through practising their use, a process he called interiorisation.

Polanyi also considered the reverse of this process, where the focus of the practitioner’s attention was returned to the principles. The immediate result of this is often a complete loss of meaning; “By concentrating attention on his fingers, a pianist can temporarily paralyse his movement” (ibid p. 18). However, Polanyi believed the long-term effect need not be negative, destructive analysis of such knowledge followed by re-interiorisation could result in a better developed basis for practice (ibid p. 19).

Figure 7. Interpretation of Polanyi's theory 2.

Our research suggested a need develop an understanding of how tacit knowledge is acquired. Polanyi’s work implies that such knowledge is gained experientially, through undertaking the actions and absorbing the principles. This project aims to enable new practitioners to tap into the accumulated knowledge of previous generations of practitioners. Polanyi (1966, p. 30) described the means by which such knowledge was learned as a process of indwelling: the novice seeks to dwell in the actions of the expert through observing them and taking action to imitate them.

In her study of the great Japanese ceramicist Shoji Hamada, Susan Peterson (1974) described the relationship between deshi (apprentice) and master: “To learn as a deshi means to submit one’s self to the master, to leave one’s own self, to become ‘in’ the master. This ‘surrender’ to the master does not mean just blind imitation, but gives a spiritual discipline and the opportunity to absorb a skill into one’s bones” (p. 46).

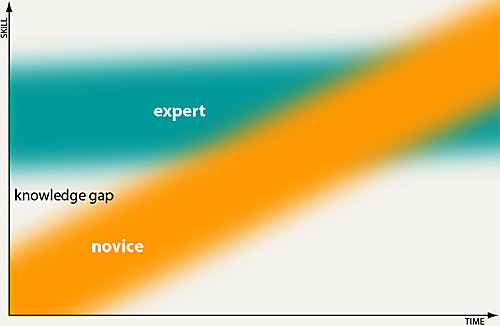

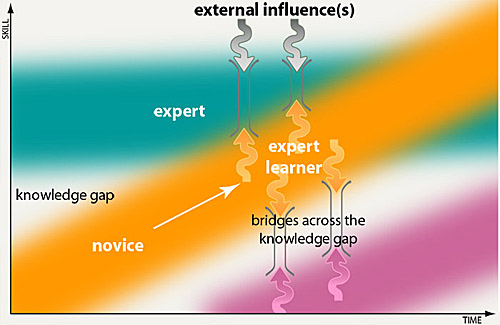

However, Wood (2006, p. 126) observed that, at an early stage of learning, it was very difficult for a novice craft practitioner just to observe and imitate successfully. Even the expert learner in our pilot study struggled to imitate what she was observing and equally the craftsman was unable to find words to explain what she should feel for when grinding. According to Polanyi, the difference between the skill of a novice practitioner and that of an expert is “a gap to be bridged by an intelligent effort” and Schön (1987) similarly referred to “an apparently unbridgeable communication gap” (p. 101) between them. The diagram below (Figure 8) is not intended to be a measurable graph, but more a visual aid, a representation of this concept. It shows the potential progression of a novice practitioner’s skill in relation to that of an expert over time and the initial ‘knowledge gap’ that exists between the two:

Figure 8. The knowledge gap between novice and expert practitioner.

Polanyi (1966) only views this gap from the perspective of an expert, explaining “Our message had left something behind that we could not tell, and its reception must rely on it that the person addressed will discover that which we have not been able to communicate” (p. 6). The onus in his terms is on the novice practitioner to understand through intelligent effort. However Schön (1987) suggested the solution was in “reciprocal reflection-in-action” (p. 120), implying that the expert practitioner needed to make as much effort as the novice in the process of bridging the gap. The novice must engage in reflective imitation, where they copy the expert whilst reflecting on the feedback from their own actions. The expert must view the novice’s actions in response to instruction as revealing the meaning they had constructed for that instruction. They must observe reflectively and amend or add to their instruction until they felt there was a convergence in meaning (Schön, 1987, p.104).

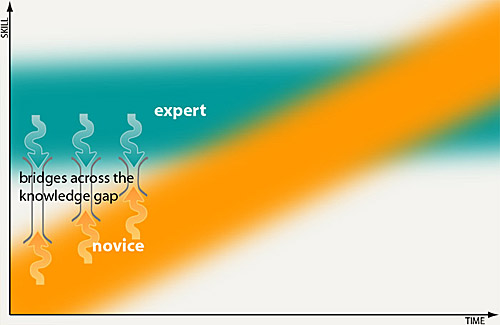

Reciprocal reflection-in-action was observable in the exchange between the expert learner and the master grinder after the expert learner had her first experience of grinding. The craftsman suggested a movement to feel how the blade was sitting on the stone, the expert learner responded to confirm her understanding, then she had a starting point to work towards the correct angle. In this situation the novice and expert practitioners could be seen to be working together to bridge the gap between them (see Figure 9).

Figure 9. Bridging the gap between novice and expert.

It is important to note that this does not imply that the tacit knowledge of the expert practitioner was made explicit. There are undoubtedly a wide range of factors, both auditory and kinaesthetic, that the craftsman takes into account when determining the angle that the blade meets the stone. Some of these he may be able to talk about, some he may not. However, these factors are not the expert practitioner’s tacit knowledge, they are explicit concepts which can help the expert articulate his tacit knowledge; they are potentially bridges across the knowledge gap which help the novice dwell in the practice of the expert.

Our discussion so far has described the problem and some existing theory, including ideas previously developed in Nicola Wood’s doctoral work. This is helped by the fact that blade grinding expert was a good instructor, allowing us to see some aspects of knowledge exchange in action. The main case study has gone further in introducing the practice of working with an expert learner as a key part of the process of developing learning materials to create these explicit bridges as illustrated in Appendix 1. This particular example, refined through a trial and error process with learners, provides an overview of the process and some step by step instructions with video demonstrations to bring the learner to a point where reflection on the process and refinement of technique is possible.

This part of the project also introduced a further new element because the knife making expert was clearly reluctant to engage in reciprocal reflection. The knife making expert had accumulated a large store of tacit knowledge over many years work but was unwilling to engage with the expert learner’s desire for destructive analysis and seemed keen for her to ‘learn the hard way’ as he had done. Had she been more of a novice, this could have presented a barrier to her learning for our goals, but as an expert learner she already possessed enough knowledge to learn without needing bridges across the knowledge gap.

It is noteworthy that the expert learner in this case, and other learners whose engagement with earlier research in this programme had provoked the concept of the expert learner, shared some common characteristics. They had taken the initiative to seek out opportunities to develop new skills, sometimes with reluctant masters, and they had the ability to advance quickly to a good level of competence. They were also independent-minded individuals who were not afraid to question or challenge their master.

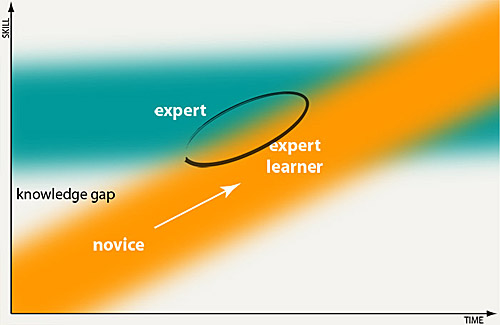

In the main case study with the knife maker the expert leaner was in a position of being able to observe and tacitly gain an understanding as she worked thus as shown in Figure 10.

Figure 10. The expert learner having progressed beyond the knowledge gap.

Her next move, rather than simply allowing the knowledge to become internalised, was to immediately attempt to articulate the knowledge through communication both with the designer and with more novice learners. Her feeling about this was that, because it was recently acquired knowledge she had no need to defend her interpretation of it, so was quick to engage in reciprocal reflection. The external influence of the designer and developing learning resource provided structure and focus to the reflective process allowing bridges to be formed across the knowledge gap between the expert learner and novice learners:

Figure 11. Bridges across the knowledge gap between expert leaner and novice learners.

The success of the online learning resource is reflected in the knives made by the learners during this period (Figure 12). Not only were these learners able to undertake techniques they had previously been unable to grasp, but the knives they made demonstrated the high level of personal creativity that was also stimulated. The outcome of this project exceeded our expectations in that some of the learners made knives supported purely by the online learning materials. It had initially been envisaged that they would also need some direct contact with an experienced practitioner to learn the skill.

Figure 12. Some of the knives made by learners during the project.

This work was done with a group of mature, independently motivated amateur craftsmen, arguably an ideal group to use self-directed learning material. For the next stage of this research we plan to develop and test a learning resource with younger learners in a more formal, structured environment, having identified some suitable professional technical skills used in professional design practice.

Discussion and Conclusions

During this research, collaborative work between the designer and expert learner was successfully used to elicit, record and transmit complex craft skills. The research has provided two contributions to our understanding of craft learning: An elicitation strategy that employs an expert learner to uncover the skilled knowledge of master craftsmen, and a transmission strategy based on the concept of bridges to assist the design of learning resources for novices. One of the motivations for developing the elicitation strategy was to enable craft masters to overcome the difficulty they many have in questioning their own understanding of their skills. This can be seen in the exchanges between the knife maker and expert learner.

This problem was discussed by Chris Argyris (1995) who observed that individuals had two distinct theories of action: espoused theories and theories in use. Their espoused theories consisted of the beliefs, values and attitudes which they advocated employing. Their theories in use were those they actually employed, of which they were not always aware and these were not always consistent with their espoused theories. When an individual discovered a gap between their espoused theory and their theory-in-use their natural tendency was to preserve their espoused theory, or at least minimise damage to it, by seeking an easy explanation for the difference: this was what he referred to as ‘single-loop’ learning.

More unusual, but from his observations by far a better strategy, was for the individual to use the perceived difference between the theory in use and the espoused theory as a means of re-assessing the governing values behind the espoused theories: what he called ‘double-loop’ learning. The key issue was that double-loop learning was far more than just reflecting on the actions taken in single-loop learning. It required the individual to undertake actions to challenge their established view of their whole practice (Argyris, 2003).

One of the concepts behind our research is to create a role for the expert learner which allows a process akin to double-loop learning to take place within the group if not within the individual. Thus the craftsman’s resistance to destructive analysis was not a problem because the expert learner had sufficient skill to proceed with the assistance of flow charts from the collaborative analysis of learning sessions.

By undertaking experimental making on her own and then immediately passing on her knowledge to a variety of more novice learners, the expert learner was able to develop her skills while retaining her explicit understanding. Since this knowledge was quite new to the expert learner she felt no need to defend it when questioned by the novice learners and was happy to adapt her interpretation to improve understanding. The parallel work of the designer provided structure and focus to the progress of the expert learner’s skill development. This included recording processes and maintaining and updating the developing learning resource

The transmission strategy draws on theories from Polanyi, Dewey and Schön which were used previously by Wood (2006, p.107) to construct a model of craft learning tested in the preceding research. The learning materials use the understanding gained by the expert learner and designer to construct bridges in the form of relatively simple and explicit task descriptions. These are not an encapsulation of the expert’s knowledge but provide a bridge sufficient for the novice to move on in their development and approach a level where they can engage directly with the knowledge of the expert. That might be through working directly with others or through observation of video material and artefacts.

In this paper we are not attempting to devalue the experience of working with a master craftsman, only to refocus where its value lies. As Lave and Wenger (1991) explained “the important point concerning learning is one of access to practice as resource for learning, rather than instruction” (p. 85) and this access to practice needs to include more than just access to master craftsmen. Involvement in a community of practice with peer support and critique is necessary to enable students to evaluate and improve on the quality of their work; traditionally working with a craft master has been the main way to achieve this. The implication from this research is that this community of practice could also effectively be provided online and we plan to test this in our ongoing research.

This project has integrated the elicitation and transmission strategies and allowed us to evaluate them in a single design project. The combination of these two elements allowed for the development of a practical system that is valuable to other designers wishing to undertake such work. An expert learner works with an expert practitioner, observed by the designer. The expert learner then undertakes experimental making on their own, collaborating with the designer to identify potential bridges into understanding the practice. The designer forms the bridges into a prototype learning resource largely using text and simple images, supported by video as overviews and representation of key dynamic processes. The material is developed and tested through the expert learner working with more novice learners observed by the designer who will shape it into the final resource. As part of our ongoing research we plan to test the generalisability of this system through a program of work with University design lecturers developing their own online learning materials under the guidance of Nicola Wood.

The learning materials from the knife making project are now online (Wood, 2009) so can easily be made accessible to a range of different craftspeople. During the course of the research they were used by a variety of learners, some of whom used it for support after initial tuition from the expert learner; some solely used the learning resource. That they were successful in their making indicates the successful transmission of the craft skill.

The research went beyond its own aims in demonstrating that some learners were able to develop new refined skills working entirely alone with the help of the learning resource and advice from peers in their online forum. It is conventional to assume that physical making skills are best developed in a physical community as would be found in both art and design education and traditional apprenticeships. This was one of the working assumptions of this research and it is very interesting to discover that it is not a universal truth and techniques can be developed to transcend it in at least some circumstances.

As described above, the novices, including makers who relied purely on the online resources and support from their online community, were able to move on within a few weeks to making very competent folding knives, not only demonstrating the ability to make a technically functional knife but to produce knives that were innovative in their form. One of the ideas behind this research has been the hope that it could help recapture some of the quality of the pre-industrial approach to craft skills, in which artistry and innovation were a normal feature. The industrial craft tradition in many fields of work has tended to emphasise utility and the more creative aspects of the work have devolved to professional designers. This project has shown that we can use new methods to transplant skills outside the industrial setting into the hands of people who have the motivation to innovate.

Acknowledgements

This work was supported by a two-year UK Arts and Humanities Research Council Grant “Transmitting Craft Knowledge”. We are grateful for the expertise and help given by the expert knife-maker Jeff Durber as an advisor to the project and to the master craftsmen who allowed us to observe and describe their work. We also depended on the support of members of the British Blades Forum (http://www.britishblades.com/forums/), especially those who took part as volunteer learners and contributed their excellent work to the project. Advice and encouragement was received from two leading manufacturers: Taylors Eye Witness of Sheffield and Spyderco of Golden, Colorado and from a traditional craft guild, The Company of Cutlers in Hallamshire, in Sheffield.

Endnotes

1 On-line software that allows users to collaboratively create, edit, link, and organise the content of a website.

2 This is purposefully represented as two separate processes above and below the dotted line as we do not wish this to be interpreted as a cyclical process.

References

- Argyris, C. (1995). Action science and organizational learning. Journal of Managerial Psychology, 10(6), 20-26.

- Argyris, C. (2003). A life full of learning. Organization Studies, 24(7), 1178-1192.

- Dewey, J. (1966). Democracy and education. In F. W. Garforth (Ed.), John Dewey: Selected educational writings (pp. 181-196). London: Heinemann.

- Edwards, J. S. (2003, September 2). Knowledge engineering: A forgotten element in knowledge management. Keynote Presentation in the Operational Research Society Annual Conference. Retrieved October 12, 2004, from http://www.orsoc.org.uk/conf/previous/or45/OR45_KnowledgeEngineering.doc

- Ehn, P., & Kyng, M. (1991). Cardboard computers: Mocking-it-up or hands-on the future. In J. Greenbaum & M. Kyng (Eds.), Design at work: Cooperative design of computer systems (pp. 169-195). Hillsdale, NJ: Lawrence Erlbaum.

- Epstein, S. R. (2004). The generation and transmission of technical knowledge in pre-modern Europe, c.1200-c.1800. Paper presented at the Global Economic History Network Annual Conference. Retrieved January 15, 2005, from http://www.lse.ac.uk/collections/economicHistory/GEHN/GEHN%20Conference%204%20Papers.htm

- Ertmer, P. A., & Newby, T. J. (1996). The expert learner: Strategic, self-regulated, and reflective. Instructional Science, 24(1), 1-24.

- Leon, N. (2005). The invisible ethnographer: Working with people, real life and up close. In Proceedings of the 58th Annual ESOMAR Congress (pp. 129-137). Retrieved February 15, 2009, from http://www.esomar.org/web/publication/paper.php?id=1231

- Peterson, S. (1974). Shoji Hamada: A potter’s way and work. London: A & C Black.

- Polanyi, M. (1958). Personal knowledge: Towards a post-critical philosophy. London: Routledge & Kegan Paul.

- Polanyi, M. (1983). The tacit dimension. Gloucester MA: Peter Smith.

- Rittel, H. W. J., & Webber, M. M. (1984). Planning problems are wicked problems. In N. Cross (Ed.), Developments in design methodology (pp. 135-144). Chichester, UK: J Wiley & Sons.

- Schön, D. A. (1987). Educating the reflective practitioner: Toward a new design for teaching and learning in the professions. London: Jossey-Bass.

- Schön, D. A. (2005). The reflective practitioner: How professionals think in action. London: Ashgate.

- Shadbolt, N., & Milton, N. (1999). From knowledge engineering to knowledge management. British Journal of Management, 10(4), 309-322.

- Smith, M. K. (2001). Kurt Lewin: Groups, experiential learning and action research. Retrieved December 12, 2006, from http://www.infed.org/thinkers/et-lewin.htm

- Wood, N. (2004). Unknown knowns; Knowledge elicitation for multimedia in craft learning. In Proceedings of the Challenging Craft Conference. Retrieved December 1, 2006, from http://www.nicolawood.net

- Wood, N. (2006). Transmitting craft knowledge: Designing interactive media to support tacit skills learning. Unpublished doctoral dissertation, Sheffield Hallam University, Sheffield, UK. Retrieved December 1, 2006, from http://www.nicolawood.net

- Wood, N. (2009). Foldingknives. Retrieved May 15, 2009, from http://foldingknives.designinquiry.wikispaces.net/

- Wood, N., & Rust, C. (2003). Designing for tacit learning: An investigation of design strategies for multimedia supported learning in the crafts. In Proceedings of the European Academy of Design Conference. Retrieved December 1, 2006, from http://www.nicolawood.net

Appendix

Appendix 1. Sample screen shots from knife making wiki

Home page with visual overview of the process and clickable images:

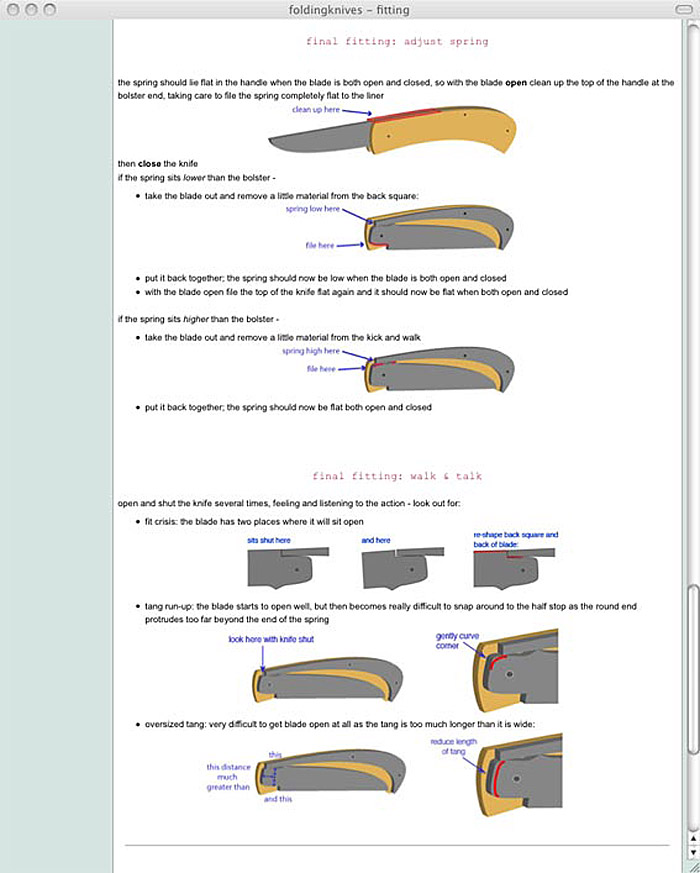

The following two pages illustrate the “bridges” that support the learner in creating the personal or tacit knowledge they need to achieve mastery. While the learning resource cannot make tacit knowledge explicit, these bridges enable a form of transmission between master and learner.

Instructional page showing illustrated step-by-step and overview video:

This "bridges" between learner and expert in two ways. The written prescription gives a relatively reliable formula although the learner will discover that each knife requires some work to refine it beyond this prescription. The red sketches convey a sense of the working practice involved in planning and laying out the work.

Part of help page showing how to assess the action of a folding knife and correct faults:

This provides a starting point for the reflective process of evaluating and refining the knife mechanism. It is sufficient to help the learner to begin to recognise problems, but the actual 'knowledge' of making is acquired by feel and experiment. The language used here comes from the expert learner - terms that she used to talk through the problems she encountered.