When the Material Grows: A Case Study on Designing (with) Mycelium-based Materials

Elvin Karana 1,*, Davine Blauwhoff 1,2, Erik-Jan Hultink 1, and Serena Camere 1

1 Delft University of Technology, Delft, The Netherlands

2 Centre of Expertise Biobased Economy, Breda, The Netherlands

Diverse forms of material expressions can be achieved through practices that cross-fertilize biology and design. Growing Design is one such practice in which designers grow materials from living organisms, such as bacteria, algae or fungi. While this emerging practice may facilitate novel product ideas, the grown materials, to date, are often used in applications as surrogates for conventional materials. A recently introduced method, Material Driven Design (MDD) (Karana, Barati, Rognoli, & Zeeuw van der Laan, 2015), can support designers in finding novel application ideas for a material in development, by providing the ways in which the unique technical and experiential qualities of the material are emphasized and bridged in an appropriate and creative manner. The present paper explores the journey of a product design master’s student, who followed the MDD method through a six-month graduation project, in search of a product application idea for a material that is intentionally grown for design purposes, namely, mycelium-based materials. We provide a practical understanding of how the material-driven design process evolves when the material grows, and elaborate on the product application concept through the lens of materials experience, which is the main motivation for the research and design activities throughout the project. We further speculate on the tools and activities that the student incorporated in the design process to tackle uncertainty as to the micro-organism’s agency, its unique temporality, and the acceptance of the material in society.

Keywords – Growing Design, Mycelium-Based Materials, Material Driven Design, Materials Experience, Material Acceptance.

Relevance to Design Practice – Growing Design is a relatively novel design practice in which designers grow materials from living organisms, such as bacteria, algae, or fungi. This paper provides a theoretical and practical understanding of how a product designer might go about finding a meaningful product application when the material grows.

Citation: Karana, E., Blauwhoff, D., Hultink, E. -J., & Camere, S. (2018). When the material grows: A case study on designing (with) mycelium-based materials. International Journal of Design, 12(2), 119-136.

Received March 17, 2017; Accepted March 11, 2018; Published August 31, 2018.

Copyright: © 2018 Karana, Blauwhoff, Hultink, & Camere. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: E.Karana@tudelft.nl

Elvin Karana is Associate Professor of Design Engineering at Delft University of Technology. Her research explores unique ways of understanding and designing (with) materials to radically change and enhance the relationship people have with materials of artefacts. She is published in the Journal of Materials and Design, Design Issues, Journal of Cleaner Production, International Journal of Design, International Journal of Sustainable Engineering, International Journal of Technology, and Design Education, and her work has been presented at the ACM conferences Computer Human Interaction (CHI) and Design Interactive Systems (DIS). She is the main editor of Materials Experience: Fundamentals of Materials and Design and the founder of Materials Experience Lab.

Davine Blauwhoff is a designer focused on new material development and product design. She has a background in Industrial Design and studied at Eindhoven University of Technology, Design Academy Eindhoven and Delft University of Technology, Industrial Design Engineering. This paper describes her master graduation project for which she received her MSc. diploma in May 2016. In the meantime she has gained more experience in Material Driven Design, collaborating with the Amsterdam University of Applied Science (AUAS) on a project with recycled waste textile. Furthermore she has presented her work in several exhibitions and is co-author of a publication from AUAS on re-use of textiles in bio-composites. Currently she works at the Centre of Expertise Biobased Economy, where she is leading a research project on mycelium composite material.

Erik Jan Hultink is professor of new product marketing in the Faculty of Industrial Design Engineering at Delft University of Technology in The Netherlands. He received his M.Sc. in economics from the University of Amsterdam and his Ph.D. from Delft University of Technology. His research investigates means for measuring and improving the process of new product development and launch. He has published on these topics in such journals as International Journal of Research in Marketing, Journal of the Academy of Marketing Science, Journal of High Technology Management Research, Industrial Marketing Management, R&D Management, IEEE Transactions on Engineering Management, and Journal of Product Innovation Management.

Serena Camere is a design researcher with a keen interest in biodesign, materials and sensoriality, developing methods and tools that help unpacking the experiential potential of emerging technologies. After her studies in Industrial Design, she received her Ph.D. title cum laude in March 2016 at Politecnico di Milano. During her Post-Doc at Delft University of Technology, she worked on the project Mycelium based materials for product design (NWO-STW), conducting a series of characterization studies that investigated the technical and experiential performance of mycelium-based materials. Her scientific research has been published in several peer-reviewed conference and international journals. Beside her academic activities, Serena constantly seeks opportunities to disseminate her work through exhibitions (Biofabricate 2017, Dutch Design Week, Milan Design Week), workshops (Creative Marathon at Elisava) and talks, aiming to discuss the potential of a multisensory, experience-oriented approach to industrial design and sustainable materials development.

Introduction

Reducing the use of non-renewable natural resources is a global sustainable development strategy. One solution, initiated in the last few decades, is the use of new bio-based materials in product design (Álvarez-Chávez, Edwards, Moure-Eraso, & Geiser, 2012; Alves et al., 2010; Ashby, 2013; Crabbé Jacobs, Van Hoof, Bergmans, & Van Acker, 2013; Haide & Eder, 2010; Geiser, 2001). Alongside relatively well-known bio-based materials, e.g., bio-plastics like Poly-Lactic Acid (PLA), materials made by bacteria, algae, or fungi are increasingly used in product design as innovative bio-based alternatives. These alternative materials have sparked the emergence of a new design practice at the intersection of design, materials science, biology, arts and crafts, which radically changes the role of the designer from a passive recipient to an active maker of materials (Karana et al., 2015; Myers, 2012; Ribul, 2016; Rognoli, Bianchini, Maffei, & Karana, 2015. See Figure 1 for three examples).

Figure 1. Vases grown from fungi (left), by Maurizio Montalti; shoes made of bacterial cellulose (middle), by Suzanne Lee; a water bottle made from algae (right), by Ari Jónsson. (©Officina Corpuscoli, ©Suzanne Lee; ©Ari Jonsson. Reprinted with permission).

This approach, often named Growing Design (Camere & Karana, 2017; Ciuffi, 2013; Montalti, 2010), refers to growing materials from living organisms to achieve unique material functions, expressions and sustainable solutions for design. Growing Design originates from advances in biotechnology that were initially developed for the fabrication of biological tissues, such as skins and organs for medical purposes (Mironov et al., 2009). The fascinating opportunity to co-create with nature, the diverse forms of expressions that can be achieved, and the possibility to reimagine the paradigms of production towards more sustainable solutions motivate the cross-fertilization of biology with art, architecture, and design (Myers & Antonelli, 2012). In Growing Design, designers collaborate with biological organisms, guiding their growth and forging the conditions in which a material/product is created. In most cases, designers focus on the development of novel materials, exploring the range of properties by controlling the growth of the organism (see, for example, bio-fabricated leather, produced by Modern Meadow, http://www.modernmeadow.com/press-release/modern-meadow-launches-zoa-the-first-ever-biofabricated-leather-material-brand/); or by experimenting with different shape possibilities by directly growing materials into a desired product idea (see, for example, the project Interwoven by Diana Scherer, http://dianascherer.nl/).

Other approaches that explore the potential of harnessing living systems for design purposes involve, for example, the manipulation of genomes, as in the case of augmented biology (see e.g., Agapakis, 2013; Collins, 2012; Ginsberg, Calvert, Schyfter, Elfick, & Endy, 2014), and digital bio-fabrication, which integrates advanced computer technologies in designing with living organisms (see e.g., the work of the Mediated Matter group at the MIT Media Lab; Bader et al., 2016; Dade-Robertson, Figueroa & Zhang, 2015; Parkes & Dickie, 2013). Alternatively, the designers envision a provocative far future, as in the case of bio-design fiction (see e.g., the work of Collet, 2012; Congdon, 2013; Dunne & Raby 2013). There are a number of projects that successfully bridge two or more approaches at the intersection of biology and design (see for an overview, Camere & Karana, 2018). Compared to the other listed approaches, the practice of Growing Design is closer to craft, as it is rooted in hands-on manipulation and making, and it is more convenient for the fabrication of consumer products. Consequently, we consider Growing Design as an emerging practice in product design and focus on this particular practice in the remainder of the paper.

The rising number of design exhibitions such as—Fungal Futures, 2016 (http://www.fungal-futures.com/), This is Alive, 2013 (http://thisisalive.com/) and the Bio-fabricate symposium (http://www.biofabricate.com/)—as well as the establishment of online communities—e.g., Growing Materials (https://plus.google.com/communities/116984929618483037920) and bio-labs (e.g., Open WetLab at Waag Society, NL)—are clear indications of interest among design (research) communities towards the production of materials and products from living organisms. In Growing Design, the outcome of the design effort is often a product application concept. Nevertheless, existing application concepts are often hypothetical (e.g., A. Jónsson’s algae bottle, which is not feasible to produce as a consumer product in its current state of development, Figure 1, right), archetypical (e.g., M. Montalti’s mycelium-based bowls and vases, which have typical shapes one can immediately associate with a vase/bowl, Figure 1, left), and/or they use the grown material as a surrogate for a conventional material. For example, shoes made of bacterial cellulose by Suzanne Lee (Figure 1, middle) are neither hypothetical nor do they have an archetypical shape. The material is used as an alternative to leather. We posit that three potential reasons may explain this outcome: (1) the utmost attention is paid to the specification of materials, so that there is limited time to explore innovative applications; (2) the material may have some technical limitations (e.g., not resilient enough, or it might biodegrade when subjected to water), which may limit the design space for innovative application ideas; and (3) the overall aim is often to introduce a new material as a sustainable solution to a wider public, and, accordingly , the designers prefer to create material demonstrators (Barati, Karana, Jansen, & Hekkert., 2016; Lindberg, Béland, Edström, Granberg, & Berthold, 2016) with utility functions that are ambiguous, not definitive, or they adopt basic product application ideas, such as bowls, to manage expectations concerning function and utility (see e.g., Parisi, Rognoli, & Ayala Garcia, 2016). In order to introduce a novel material to a wider public (i.e., both to other designers and consumers), designing a meaningful product application that mobilises the unique technical and experiential qualities of a material, and bridges these qualities in an appropriate and creative manner, plays an important role. We refer to this holistic approach as ‘design for material experiences’ (Karana et al., 2015).

Nevertheless, coming up with a meaningful product application concept, i.e., designing for material experiences, is not straightforward. It requires a critical understanding of what the material offers, in terms of function/utility and overall experience: how it gratifies or disturbs our senses, what meanings, associations, and emotions it evokes, and what it makes us do (Giaccardi & Karana, 2015). A recently introduced method, Material Driven Design (MDD) (Karana et al., 2015), provides a step-by-step approach to design for material experiences, when a particular material is the point of departure in the design process. By merging technical and experiential understanding in the process of material driven design, these researchers argue that the method can inspire meaningful material applications.

Following the journey of a product design student (the second author) who utilized the MDD method in her Master’s graduation project (which concerned the design of a product application for a growing material, namely, mycelium-based materials), we provide a practical understanding of how the design process evolves as the material grows. We were interested in understanding, firstly, what tools and activities the student used to support the design process? Secondly, how would the product application idea differ from existing applications for mycelium-based design; especially, when the research activities are primarily motivated by the materials experience thinking? We will elaborate on the design process and outcomes to provide initial insights for the future of Growing Design research and practice. The following sections first introduce the mycelium-based materials and briefly present the MDD method.

Mycelium-Based Materials in Design

Mycelium is the network of interwoven, thread-like hyphae that constitute the vegetative part of mushrooms. A ‘hypha’ is the most basic developmental unit of filamentous fungi, which grows by extending and branching their hyphae into a substance (Kavanagh, 2011). The industrial potential of fungi has long been explored in human history, from the production of food (e.g., cheese, bread, and beer are three examples) to medical biotechnology (e.g., antibiotics and antivirals; Wainwright, 1992). However, fungi have only recently been considered and explored as alternative resources for bio-based materials for artefacts (Holt et al., 2012; Jiang Walczyk, Mooney, & Putney, 2013).

Mycelium-based materials are grown by two alternative methods: either exploiting the abilities of mycelium to interlock other substances within its network to form a bulk material (mycelium-based composites; Figure 2, left), or harvesting a liquid culture of mycelium (pure mycelium; Figure 2, right) (Haneef et al., 2017; Holt et al., 2012).

Figure 2. Mycelium-Based Composite (left) and Pure Mycelium (right).

Mycelium-based composites are fabricated by inoculating an individual strain of fungi in a substrate of organic substances (Holt et al., 2012; Jones, Huynh, Dekiwadia, Daver, & John, 2017). The vegetative mycelium degrades and colonizes the organic substrate, using the products of degradation as feeding elements to extend its hyphae from the tip, while branching new hyphae and fusing them together to form a denser network (Pelkmans, Lugones, & Wösten, 2016). The substrate should provide the necessary nutrients for the mycelium to grow, such as carbon (e.g., glucose or fructose), nitrogen, minerals, and vitamins, together with water, the most essential of all; for this reason, the substrate should be prepared by adding the correct percentage of water (Carlile, Watkinson, & Gooday, 1994; Deacon, 1980; Jones et al., 2017). Suitable media for a substrate can be retrieved from the waste streams of agriculture, like wheat or rice straw, from wood sawdust or from other fibres like flax and cotton (Kavanagh, 2011). The type of substrate chosen significantly influences the technical and experiential qualities of the resulting material.

Pure mycelium materials are instead obtained from a liquid culture of mycelium. The liquid fermentation of fungal micro-organisms can happen in static or machine-shaken containers. When grown in a static liquid culture, filamentous fungi form a mat of hyphae at the surface of the liquid. When dried, the resulting material can vary in properties and resembles leather, paper or plastic. Depending on the additives provided to the mycelium at the end of its cultivation (e.g., glycerol or ethanol), the outcome can vary in colour, translucency and stiffness (Appels, 2014; Blauwhoff, 2016).

The fabrication of mycelium-based materials requires proper sterilization to achieve appropriate results and prevent contamination by other organisms (Carlile et al., 1994; Jones et al., 2017). This includes the substrate on which the mycelium will grow, as well as the environment in which the fabrication occurs. The culture of mycelium should then be maintained at controlled environmental conditions of light, temperature and moisture to ensure stable growth within two to three weeks (Carlile et al., 1994). The optimal conditions of temperature and moisture vary considerably depending on the strain of fungi employed; however, most species grow well around 25-35°C (Jones et al., 2017). As water is essential for fungal metabolism, the right conditions of humidity should be maintained around 60-65% in order to prevent the substrate from drying (Carlile et al., 1994). Conditions of darkness are also preferable not only to prevent the formation of fruiting bodies, but also to favour the rapid growth of mycelium (Deacon, 1980). At the end of the growing process, the mycelium can be killed by drying the material at a minimum of 60°C (Kavanagh, 2011), or leaving it at room temperature to preserve the organism in a hibernated state and to maintain the possibility of future growth.

One unique feature of the material is that it can be grown in a mould, which allows designers to grow the mycelium directly into the shape of the final object. Processing techniques such as laser-cutting and cold and heat compression can also be applied to achieve the required shape and structure for the grown material (Jiang, Walczyk, McIntyre, & Bucinell, 2016). That said, sawing and laser cutting are less preferred as they break the outer layer of mycelium (i.e., the skin), affecting the material’s properties at both technical and experiential levels. The skin of the mycelium increases the material’s compressive strength (Yang, Zhang, Still, White, & Amstislavski, 2017) and its water repellence, as well as enhances its aesthetic properties by wrapping the organic substrate in a uniform surface. In general, based on the applied technique, the qualities of the material can change to a great extent. For example, when it is heat pressed, it resembles MDF or OSB boards, whereas it is similar to foam when it is only cured but not pressed.

Leading in the research and development of mycelium-based materials are creative scientist Philip Ross and the US-based company Ecovative, which was founded in 2007 by Eben Bayer and Gavin McIntyre, two graduates in Mechanical Engineering and Innovation Design from the Rensselaer Polytechnic Institute (see Ecovative website, http://www.ecovativedesign.com/). With an initial focus on insulation, they introduced compostable mycelium-based packaging material as a replacement for traditional Styrofoam (Holt et al., 2012). Current developments from the company extend towards consumer products. In 2009, arti st, designer and inventor Philip Ross created Mycotecture Alpha, a small teahouse constructed from mycelium bricks. MycoWorks—founded by Philip Ross, Sofia Wang and Eddie Pavlu—created a new kind of leather grown rapidly from mycelium and agricultural by-products in a carbon-negative process.

Other renowned experts in growing mycelium-based materials for design are Eric Klarenbeek and Maurizio Montalti. Eric Klarenbeek transforms the material into artistic furniture, emphasizing its freedom of shaping by incorporating advanced technologies such as 3D printing. Bridging the gap between purely functional and art, Maurizio Montalti from Officina Corpuscoli embodies the material in diverse products envisioning a bio-designed future. Figure 3 illustrates a collection of projects in the last couple of years by artists/designers/architects to show the potential of this newly emerged material to a wider public.

Figure 3. A collection of some current products and projects with mycelium based materials

(Image source: Blauwhoff, 2016. Reprinted with permission).

In 2014, Ecovative developed a Grow It Yourself (GIY) package in order to make the material available to the public in line with DIY material practices (Rognoli et al., 2015). The GIY package has opened up new possibilities for design schools such as Politecnico di Milano and TU Delft, where it has been used to support material experimentation in material design courses. A recent design graduate of the School of Design (PoliMi), Parisi et al. (2016), used the GIY package to design with mycelium-based materials. However, he mainly focused on material explorations to create new material concepts (i.e., the initial two steps of the method, see the following section), and used simple product ideas, such as cups and bowls, to present the material concepts.

As mentioned in the Introduction section, we argue that the existing cases of mycelium-based design do not yet illustrate the potential of the material for product design to its full extent. This statement shaped the assignment we gave to the product design student for her master’s graduation project, as follows: “Design a product made of mycelium-based composites, which brings forward the unique qualities of the material.” Note that we particularly focused on composites, rather than pure mycelium, as the mycelium-based composites often make use of natural waste streams and it is relatively easier to achieve a viable material in terms of shape-ability, durability, and costs compared to pure mycelium materials. Furthermore, with a limited amount of mycelium, sufficient material can be produced for material testing and design. During the six months project the student was provided with occasional guidance on the Material Driven Design (MDD) method.

Material Driven Design (MDD) Method

The MDD method aims at supporting the process of design when a particular material is the departure point in the design process. Grounded on the notion of materials experience (Karana, 2009), the method emphasizes that when experience is the expected outcome in a material driven design project, the journey of the designer leads from material properties and experiential qualities to a materials experience vision within a wider context (purpose of existence); and from this materials experience vision back to experiential qualities and material properties, and finally to products. In order to stimulate creative thinking in material driven design, tinkering with the material—a kind of explorative process of creation and evaluation—is required.

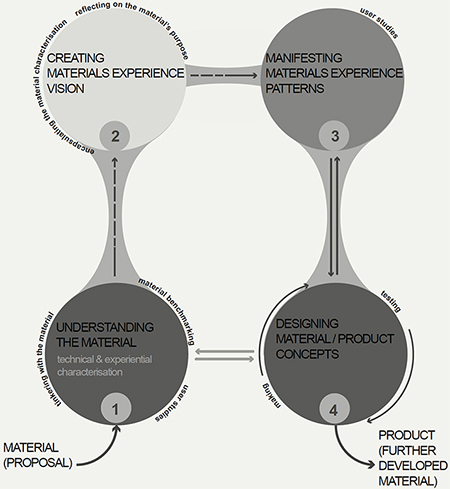

Accordingly, the MDD method states four main action steps presented in a sequential manner: (1) Understanding the Material, (2) Creating Materials Experience Vision, (3) Manifesting Materials Experience Patterns, and (4) Designing Material/Product Concepts (Figure 4).

Figure 4. Material Driven Design Method (Karana et al., 2015). (Click here enlarge the figure.)

The first step focuses on understanding the material in its broadest sense. It addresses the origin of the material and its production process, and suggests engaging in extensive tinkering to understand the material be. In this step, performance tests (technical/mechanical tests) are conducted for technical characterisation; and user studies are conducted to understand experiential qualities of the material at four experiential levels, namely sensorial (e.g., it is soft or rough), interpretive (e.g., it is modern or nostalgic), affective (e.g., it is surprising, disgusting), and performative (e.g., makes me caress, invites me to touch; Giaccardi & Karana, 2015). To position the material among existing examples, the method suggests conducting material benchmarking. Mapping the technical and experiential characterization results, and findings from the material benchmarking, the designer creates a vision, i.e., the Materials Experience Vision, in the second step of the method. The Vision represents the design goal for the material and expresses what role the material has in relation to a product, its user and context. It enables the designer to translate the material qualities into a product context (but not yet a specific product idea) where both technical and experiential qualities are taken into account. In the vision statement, certain qualities, for example, at interpretive or affective levels, come forward. These qualities (e.g., honest, surprise and playful) are extracted and explored further in the third step of the method, where the designer seeks to reveal the material experience patterns that are prevalent in society. For example, what kinds of materials/material qualities in products commonly surprise people? What kinds of materials are found playful? In the last step, the final material and product concepts are created. In this phase, the vision steers the concept development to ensure an outcome that is grounded in the unique qualities of the material, both from technical and experiential perspectives.

To date, the method has been applied in designing with a variety of materials, such as coffee waste (Zeeuw van der Laan, 2013), 3D printed textiles (Lussenburg et al, 2014), electro-luminescent materials (Claus, 2016), plastic waste (Ghazal, 2016; Majumdar et al., 2017; Veelaert, Du Bois, Hubo, Van Kets, & Ragaert, 2017), recycled textiles (Van den Dool, 2016), and recycled textiles-bioplastic composites (Oskam et al., 2017). The following section will present a master’s graduation project of a product design student, conducted at the Delft University of Technology, by the Faculty of Industrial Design Engineering, which took mycelium-based materials as the departure point in the MDD process. The first author screened the student’s process closely by direct supervision. Her process has also been analysed through written documentation (i.e., project report, and the designer’s dairy) supported by photographs and videos.

Designing (with) Mycelium Based Materials: A MDD Project

Understanding Mycelium Based Materials

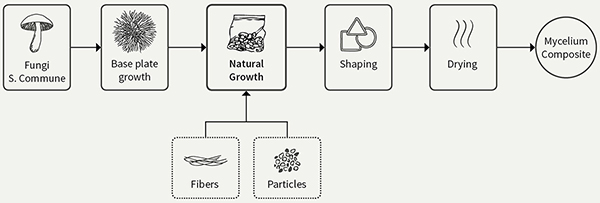

In order to understand the material, next to the specific actions suggested by the MDD method, the student approached a team of experts, including microbiologists from Utrecht University and an experienced designer in mycelium-based design, Maurizio Montalti, to gain insights on the growing conditions and ingredients for mycelium-based materials. These interviews, together with further reading on the biology of the material (e.g., Kavanagh, 2011; Madigan, Martinko, & Parker, 1997) and tinkering with the material, helped the designer to create (1) a visual diagram on how the material was fabricated as depicted in Figure 5; and (2) a material taxonomy (Figure 6), showing the categorization of variables affecting the ultimate material qualities, which will be explained further in the next section.

Figure 5. Development process of mycelium composite schematised by the designer.

Tinkering with the Material

Traditionally, materials science and engineering involves investigating the relationships between the structures (i.e., the arrangement of the material’s internal components, which can be at microscopic or macroscopic levels) and properties of materials (i.e., material traits in terms of kind and magnitude of response to a specific imposed stimulus, such as thermal properties, which are defined independent of material shape and size) (Callister & Rethwisch, 2011). In addition, two other components are involved in materials science and engineering, namely, processing and performance. Accordingly, how a material is processed (e.g., heat pressing) will influence its structure, and this will affect its properties and ultimate performance. Performance, in material driven design, is both experiential and technical.

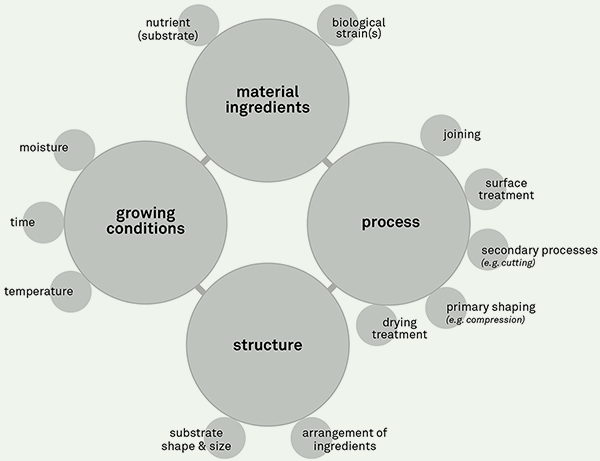

When growing a mycelium-based material, the performance of the material at both technical and experiential levels is affected by the growing conditions. For example, moisture or temperature can have a great effect on the material outcome. Figure 6 summarizes what specific variables the student took into account in her material tinkering process (note that although she conferred her taxonomy with the material experts, in order for this taxonomy to be used in future projects, further elaboration is advised). Grounded on this material taxonomy, the student conducted a series of tinkering activities to acquire a good understanding of the material and its preparation as well as to obtain suitable materials for further testing. Each activity provided new insights on the material’s nature and was built on the acquired knowledge and understanding from the previous tinkering activity. Figure 7 shows some of the initial material samples obtained through this process.

Figure 6. The material taxonomy created by the design student to support her tinkering activities.

Figure 7. Initial tinkering with the material by trying different substrates such as bread particles and orange peel (left); second round of tinkering with the material with sawdust as substrate (right).

The material experiments primarily focussed on the material ingredients. Different substrates, for example, bread particles, banana peel, coffee residue, Styrofoam pellets, flower, orange peel, carrot leaves, cardboard and straw, were used to get a better understanding of mycelium as a growing organism. The student used different substrates to explore (1) the ability of mycelium to grow on organic and inorganic materials, (2) how the type of substrate influences the speed and density of mycelium growth, (3) the extent at which the colour of the substrate is transferred to the final material. She particularly focused on waste streams as substrates to create added value.

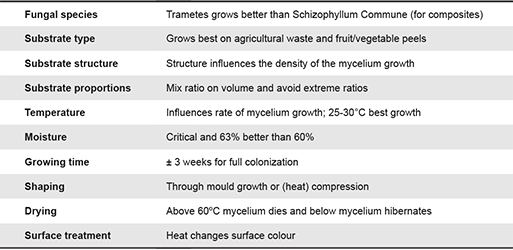

Through material tinkering, the student discovered that not every substrate was suited for mycelium growth and the growing rate and density varied in fungal species. Furthermore, it was difficult to determine when a material was fully colonized, as there was no tangible indication of that, and which aspects influenced growth. Even when all parameters were (assumed to be) met, it was hard to be sure that the material was not infected. Table 1 presents the designer’s main conclusions from the tinkering process.

Table 1. Main findings of the design student from her tinkering with mycelium-based composites.

Material Characterization

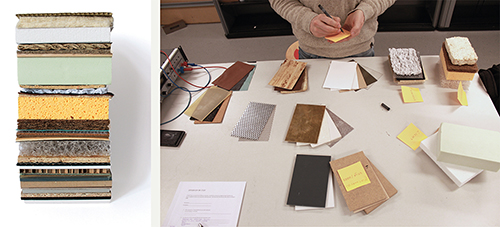

Following the tinkering process, the student selected two variables she thought would facilitate the development of seemingly different samples in terms of technical properties and experiential qualities, which at the same time would be suitable for material characterization studies: strain structure (i.e., fibre vs. grain) and compression of the grown material (i.e., not compressed vs. hot compressed and cold compressed). See Figure 8 for the developed samples included in the technical and experiential characterization.

Figure 8. The final set of material samples to be included in the technical and experiential characterisation of the material.

Experiential Characterization

The designer explored the experiential qualities of the developed material samples, which concern how they feel and what meanings, emotions, and actions they evoke, through a focus group and a categorization study. Eight students from different departments of Delft University of Technology were asked to describe the given material and brainstorm on possible product applications in a focus group setting. The student specifically invited participants from non-design related departments as they would be less familiar with the material. The samples were all experienced as light, stiff and brittle and interpreted as natural, organic, and artisanal. When interacting with the materials, the participants were discovering the material by examining it up close, smelling, touching, and pressing. An interesting performative quality was also the picking of bits from the unfinished edges of the sample and the urge to break the material.

The student also conducted a categorization study (Lakoff, 1987; Morel, 2000; Solomon, Bamossy, Askegaard, & Hogg., 2006) in order to explore under which material category people would group the mycelium-based samples she developed (Figure 9, right). Ten Industrial Design students, who were not aware of the material prior to the test, categorized 42 different materials (see Figure 9, left, for a set of example samples). This set included two mycelium samples that varied from each other: mycelium as a foam (Figure 8, top right) and as a sheet (Figure 8, bottom left). During the categorization study the participants were asked to freely categorize the materials according to their similarities based on their own insights. After grouping the materials, they were asked to name each category (e.g., natural materials, polymers, etc.) and to explain the reasons behind their categorization.

Figure 9. An impression from the categorization study and the samples used in the study.

Although the mycelium-based samples were made from the same ingredients, the processing method (e.g., heat pressing) generated variations such that they could be classified under different material categories. However, the foam-like sample, was more difficult to categorize when compared to the sheet material, as the visual attributes of the material were considered as natural, while the way it behaved when held and pressed was associated with synthetic foam materials.

The student mapped her findings with her preliminary literature review stating that easy categorization of a product increases its likelihood of adoption in society (Creusen & Schoormans, 2005; Morel, 2000). At this point in her process, she decided to focus on the notion of acceptance, and aimed to provide a framework for acceptance to support her choice of material and product concepts. Her further activities in relation to the acceptance of the material will be described in the section on Materials Experience Patterns (see below).

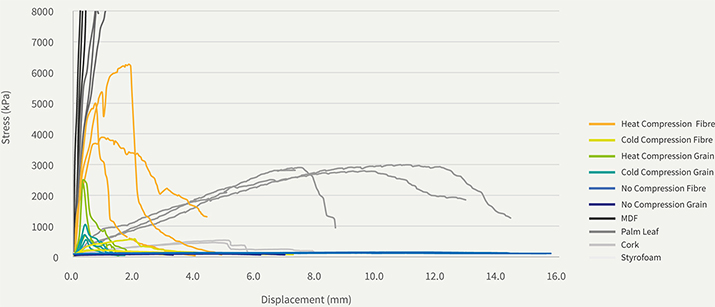

Technical Characterization

For the technical characterization, five tests were executed on the samples to assess thermal conductivity, strength, flammability, water resistance, density, and the ability to laser cut the material. These preliminary tests were conducted with available test set-ups at the university (i.e., they do not yet comply with industry standards). To acquire a better insight into the actual performance of the mycelium samples, the student included four reference materials, namely, MDF, Palm leaf, Cork, and Styrofoam, in these technical tests (Figure 10). According to the test results, she concluded that the main difference between the technical performances of the six mycelium samples was due to the processing techniques. When not compressed (foam-like samples), the material was not strong but had good insulating properties. When the material was compressed with heat, the material became much stronger, though less appropriate for insulation.

Figure 10. Tensile test results of mycelium composites in comparison to the reference materials.

Material Benchmarking

To create a proper understanding of a material at hand, the material should be positioned among other similar materials and applications. The student collected a number of existing examples and elaborated on the purpose of the material as emphasized by other designers and producers (see Figure 3, which was initially presented in the introduction section, for a snapshot from the collected mycelium-based materials and products for the benchmarking). This activity, when combined with her own findings from the material understanding, helped her to find the gaps in the marketplace.

She concluded:

In the existing examples, the material is specifically used not to be touched or interacted with. The interactions with the products are not directly linked to the qualities of the material: e.g., the (inter)action of turning on a lighting fixture (normally a switch not fixed on the lamp itself) does not result in any physical connection between the user and the material apart from visual stimuli. Furthermore, the material can grow into any form; yet in the existing examples, it is usually in conventional forms.

Materials Experience Vision

The student mapped her findings from the previous steps for material understanding to formulate a vision statement. One of her unique findings was in relation to the performative qualities of the material: the unfinished edges encouraged people to pluck bits and pieces from it, and it evoked a strong urge to break it. A similar feeling might be aroused when being exposed to bubble wrap. Accordingly, the Materials Experience Vision was formulated as follows:

Mycelium-based materials are made of solely natural substances (fungi and agriculture waste) and can therefore be discarded in nature. The naturalness of the material supports its applicability for sustainable purposes. The ability to grow (living organism), the visible fibres and irregular surface give the material a natural appearance. In combination with its brittle property (depending on how it is developed) and the urge to break the material when interacting with it, triggers the material to be something that is ‘made to be crumbled and thrown away.’ Accordingly, design a mycelium-based product that invites you and requires to be interacted with it to function; and encourages you to discard it in nature, which comes as a result of this interaction.

Material Experience Patterns: Toward Acceptance

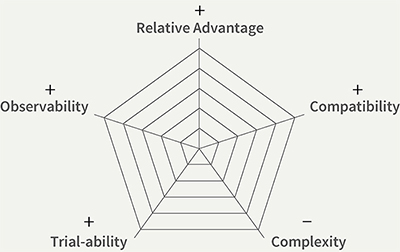

The third step of the MDD method suggests that the designer should distil one or two experiential qualities (e.g., traditional) from the materials experience vision, and translate these qualities into material and product aspects (e.g., transparency, organic form) based on material experience patterns prevalent among people within the targeted context. The student, however, preferred to focus on Materials Acceptance instead, which she considered the biggest challenge when she observed the people’s initial reactions through the experiential characterization studies. She aimed to obtain a further understanding of when people accept a new material in a consumer product, which would help her to assess the final application concepts based on their potential uptake by society. In order to develop a provisional pattern for acceptance of the material, the student explored theories from marketing and innovation management, from which the Diffusion of Innovations theory (Rogers, 1995) was the most useful one to be operationalised.

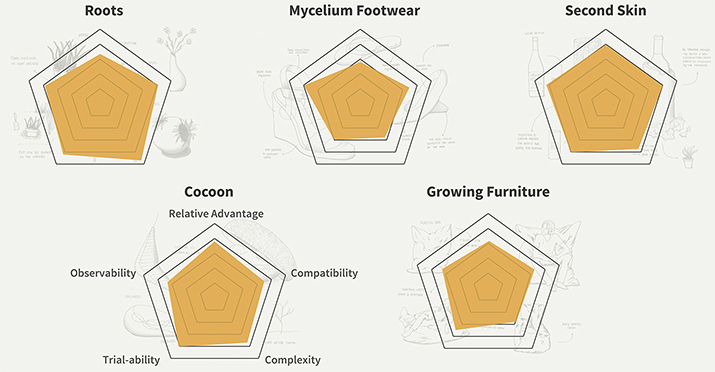

Rogers argues that the characteristics of innovations, as perceived by individuals, help to explain their different rates of adoption. Rogers identifies five perceived attributes to be taken into account: relative advantage (i.e., the degree to which an innovation is perceived as better than the idea it supersedes), compatibility (i.e., the degree to which an innovation is perceived as consistent with the existing values, past experiences and needs of potential adopters), complexity (i.e., the degree to which an innovation is perceived to be difficult to understand and use), trial-ability (i.e., the degree to which an innovation may be experimented with on a limited basis), and observability (i.e., the degree to which the results of an innovation are visible to others). Moore and Benbasat (1996) found support for the predictive validity of these innovation characteristics. For example, analysis of the observability item indicated that the more a potential adopter can see an innovation, the more likely he is to adopt it. In fact, research has shown that mere exposure [to objects] is capable of making an individual’s attitude toward these objects more positive (Zajonc & Markus, 1982). Grounded on the five characteristics of innovations, the student created a provisional selection tool (Figure 11) to be used in product concept selection in the next step.

Figure 11. Acceptance prediction spider chart based on five characteristics of innovation in relation to adoption in society (based on Rogers, 1995).

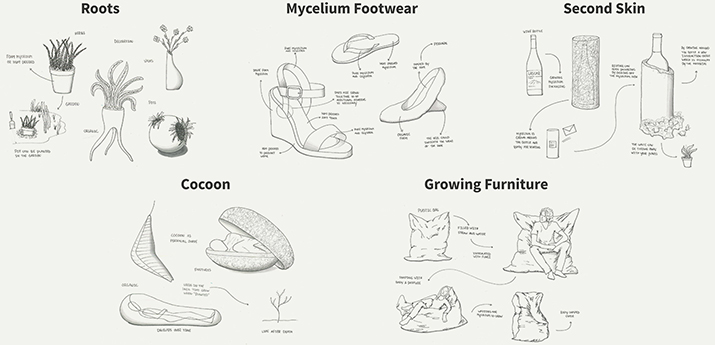

Designing Product Concepts

The concept development was grounded on the Materials Experience Vision. After a couple of brainstorming sessions, five concepts were created, ranging from a plant pot and packaging to a coffin, footwear and furniture. Figure 12 gives an overview of the created concepts.

Figure 12. Overview of the five product concepts for mycelium-based materials.

The student used the acceptance prediction spider chart (Figure 11) to analyse the concepts, and select the one with the highest potential to be accepted by society. The five concepts were evaluated by ten people (non-designers) who had physically experienced the material in an earlier study (i.e., either the categorization or focus group study). The five concepts were presented through an online survey with a short description of the concept and an overview of the five innovation characteristics by Rogers (1995) as presented in the Acceptance Prediction Spider Chart. They were asked to assess each concept within its own product category. For example, the concept of a plant pot was compared with conventional pots but not with, for example, a coffin. In this way it was possible for the student to assess the level of innovation within the product category itself. Figure 13 shows the average results obtained per concept. The student concluded that the more a concept complies with the innovation characteristics (the larger the orange surface), the more likely it will reach widespread adoption. Mapping these results with the initially created materials experience vision, the student selected the Second Skin concept to be further developed.

Figure 13. Assessing the concepts on their likelihood of adoption in society, based on the five characteristics of innovation (the outcomes of complexity have been inverted).

The Final Design: Second Skin

Second Skin is innovative packaging for (wine) bottles, in which the mycelium-based material is grown around a (wine) bottle, taking its exact form. The material protects the object as a second skin. When the skin is peeled, the bottle is revealed and ready for consumption. The performative qualities of the material are expressed in the interaction to reveal the bottle. The student particularly focused on a wine bottle packaging, as she envisioned a unique wine serving ritual asking for a ceremonial opening of the package. The material is peeled and thrown away into nature, like a snake leaving its second skin behind (Figure 14). The design emphasizes that the unique qualities of the material are: it can grow into any shape; it has high insulation and protection qualities; it can be composted; and it makes you pluck and pick it. The student preferred the foam like (not-pressed) mycelium-based materials for this concept. The listed qualities were assembled through the technical and experiential studies. She also emphasized that one of the underlying reasons behind the final material concept was that the categorization study showed that the foam-like material was difficult to be categorized by people. She noted this as an opportunity for the use of the material in the final concept, supporting the construction of meaning for a new material.

Figure 14. Final design, Second Skin, an innovative packaging for (wine) bottles.

The Second Skin was made using six steps. First, the shape of a bottle (i.e., wine, champagne) was digitalized to create a 3D model that includes an additional outer layer (i.e., 1 cm thicker than the actual bottle) that creates the space for the mycelium to grow. Secondly, this model was CNC milled from foam to act as the positive mould for vacuum forming. The third step was the vacuum forming of the final mould. In the meantime, mycelium material was being grown to allow proper colonization. The fourth step involved filling the moulds with a layer of mycelium and placing the bottle within. In the fifth step, the bottle, which was covered with a layer of mycelium, was then left to grow for approximately one week. The last step was to release the product from its mould and leave it to dry at room temperature.

Discussion

This paper presented the journey of a Master’s product design student, who designed with a growing material in search of a meaningful product application idea. The student followed the Material Driven Design Method to support the action steps in understanding the material, creating a material experience vision, exploring the experiential patterns within society and finally mapping her findings into a product embodiment. In the Introduction, we raised two main questions with regards to the design process and the design outcome: How does the design process evolve when the material grows? Whether and/or in which ways the final material application idea would be different than the existing applications of mycelium-based materials when the materials experience thinking motivates the design process?

Uncertainty in Growing Design: Opportunities and Challenges

While a material with endless combinations of its ingredients would excite and inspire designers in exploring its possibilities for design, this may also give a sense of uncertainty (Daalhuizen, Badke-Schaub, & Batill, 2009; Krishnan & Bhattacharya, 2002), as the boundaries of the material would not be known in an early stage of a material-driven design project (Barati, Karana, & Hekkert, 2015). Calling attention to the role of uncertainty in designing with smart material composites, Barati, Karana, and Foole, (2017) showed across a number of material driven design cases how various tinkering activities, physical probes and prototypes made along the design process were used to resolve uncertainty in relation to material knowledge. Next to the unknown properties and the behaviour of the material, the growing design process presented in this paper entailed a high level of uncertainty in relation to three main dimensions: (1) another form of life, a biological organism with an agency of its own (Collet, 2017), participated in the design process. Environmental conditions, such as moisture and temperature affect the growth of the organism and the final qualities of the grown material, often in unexpected ways; (2) The results of the making activities were not readily visible, as “[g]rowing design involves a delay in time of few weeks, temporally separating the moment of crafting from the evaluation of the outcome” (Camere & Karana, 2017, p.110); (3) the newness of the material as well as the established socio-cultural meanings of fungi as dirty and unhealthy puzzled the student whether the final material concept would be accepted by a wider public when embodied in a consumer product.

The first step of the MDD method suggests that tinkering with the material—playing with its ingredients, different processing techniques—helps designers to reduce the degree of uncertainty in designing with materials. To tackle uncertainty in designing (with) a growing material, next to tinkering with the material, the student adopted a couple of strategies. For example, she developed a materials taxonomy to structure the tinkering activities and to map the findings as a coherent whole. Moreover, she regularly had informal discussions with material experts to present the results of the tinkering activities and to speculate on the possible effects of certain conditions on the growing process. On the other hand, the aliveness of the material reduced opportunities for the repeatability of certain tinkering actions and sometimes resulted in accidental findings. The designer had to adapt a sense of openness to these unexpected and/or unplanned influences of nature on the material.

To cope with the separation of time from the moment of crafting and possessing the final outcome, effected by the unique temporality bond to the material’s inherent biology (i.e., it needs at least two weeks to grow), urged the designer to fill in the space between the making and having the material with constant documentation, namely a materials diary. Noting down every little change in material ingredients or environmental conditions, the student evolved a systematic understanding and a sense of control over what affected which qualities in the material.

When it comes to material acceptance, as reported by the student, the categorization study was useful in shedding light on what associations people had with the material concepts and among what other conventional materials they positioned the material. As explained earlier, in the categorization study she found that the foam-like material was difficult to be categorized by people. The student noted this as an opportunity for the use of the material in the final concept, supporting the construction of meaning for a new, unfamiliar material. Furthermore, the developed Acceptance Prediction Spider Chart grounded on acceptance of innovation theories helped the student to converge on the Second Skin product concept. We will further elaborate on the materials acceptance in the next section, under the evaluation of the product concept.

The characteristics of the growing design process that we revealed after analysing this particular case are in line with the notion of complex design practices, recently presented by Chen and Crilly (2016). According to these authors, in cases that often involve a cross-domain challenge (e.g., biology and design), rational design approaches are rarely applicable as both the internal and external states of the system are uncertain and poorly understood. In line with our findings, they list unpredictability, context dependency, non-linearity, and open systems as some of the important characteristics of such complex design practices, which should be taken into account in the development of support tools and methods for Growing Design.

The student reported that due to the absence of predefined material properties as well as the time required to grow a proper sample, the first step of the method (i.e., understanding the material) took longer time than expected. On the other hand, the possibility of producing the material and product simultaneously shortened the time required for the prototyping of the final product concept. This concurrent thinking of material and product form requires further understanding and support through novel tools and methods.

Toward Novel Product Applications in Growing Design

In order to elaborate on the product concept presented in this paper, we picked a relatively recognized example from Ecovative, mycelium-based packaging (Figure 15, left). In the Ecovative packaging, the mycelium-based material is used as a surrogate material to replace petroleum-based packaging foams such as polystyrene, polyethylene, or polypropylene. The company keeps the conventional form of the foam packaging. The combination of three main qualities—being bio-based, biodegradable, and having high protection qualities—inevitably brings the following application context opportunity: a short-life product for protecting goods. Thus, packaging is a relatively straightforward application idea for mycelium-based composites, which makes sense from the technical/environmental point of view. In the Ecovative example, by keeping the exact form of packaging made of polystyrene foam, the company tried to assure that this new and emerging material would be more easily accepted by society. In other words, the material is different, but looks typical, in a typical form, replacing an aesthetically similar material.

Figure 15. Left: Ecovative packaging for wine bottles; Right: Mush-Lume lampshade by Danielle Trofe (©Danielle Trofe; Reprinted with permission).

Typicality and novelty have often been used to explain aesthetic preferences for products (Hekkert, Snelders, & Wieringen, 2003; Hung & Chen, 2012). Accordingly, a typical product (i.e., the degree to which a product represents a category (Loken & Ward, 1990; Veryzer & Hutchinson, 1998) is often preferable to people, who wish to avert risks inherent in ventures into the unknown (Hekkert et al., 2003). Conversely, many influential studies show that consumers prefer novel products when newness, unfamiliarity and originality can alleviate boredom and saturation effects (Creusen & Schoormans, 2005; Martindale, Moore, & Borkum, 1990). Empirical studies have shown that to achieve high aesthetic appreciation among consumers, designers should aim for the best combination of typicality and novelty (Hekkert et al., 2003; Hung & Chen, 2012). The extent and ways that newness of a bio-based material should be obvious in an application, or whether the material should be used as a surrogate material, quietly unnoticed, requires further understanding to support widespread acceptance of emerging bio-based materials.

Consumer Acceptance has long been studied in marketing and innovation management, yielding many competitive theoretical models with roots in information sciences, psychology, and sociology (e.g., Davis et al., 1989; Taylor & Todd, 1995; Venkatesh & Davis, 2000). Perhaps the foremost amongst them is the Diffusion of Innovations theory by Rogers (1995). Grounded in sociology, Diffusion of Innovations theory has been used since the 1960s to study a variety of innovations, ranging from agricultural tools to organizational innovations (Tornatzky & Klein, 1982). The student adopted Rogers’ five characteristics of innovations, as perceived by individuals, to help explain their different rates of adoption. The characteristics of innovation by Rogers offer a combination of hedonic and utilitarian aspects in understanding adoption of innovations. In fact, several scholars have later critically argued that the hedonic aspects may overrule the utilitarian side in some technology adoptions (Papacharissi & Rubin, 2000; Shah, Kwak, & Holbert, 2001; Song, Larose, Eastin, & Lin, 2004). An example can be found in Bruner and Kumar (2005) who showed that “consumers are likely to have favourable attitudes to adopt handheld devices more for the fun they can have with them as for the ability to accomplish certain functions”(p. 557). Similarly, Chen, Gillenson, and Sherrell (2002) found that “while virtual stores tap the needs of time-starved consumers, they seem to be less attractive to leisure consumers, who value social interaction and first-hand experience with products, etc.” (pp. 715-716). Many of these studies also commonly argue that the experiential qualities of innovations (e.g., aesthetic attributes, their associations, etc.) inevitably play an important role in ultimate consumer acceptance. They agree that to completely account for individual choices in technology adoption, it is essential to look beyond the utilitarian aspects of the technology. We argue that new material acceptance is not an exception. Understanding the way in which the material acceptance process unfolds, in addition to simply identifying features that determine its ultimate success or failure, requires further attention.

In the Second Skin product concept, the student aimed at achieving a reasonable balance between typicality and novelty to facilitate the acceptance of the material. The foam-like material was intended to elicit a sense of familiarity when applied into packaging because of its similarity with polystyrene foam (like Ecovative). Yet, she offered a totally novel way of interacting with the material. The user study participants were constantly plucking and picking at the material. These unique performative qualities of the material inspired the student in finding a novel interaction scenario that was also introducing a new wine ritual. Furthermore, the student realized that one of the most noteworthy qualities of the material was its grow-ability in a mould, so in principle it would take any shape it grows into. She wanted to emphasize this quality, as it was particularly helpful in justifying her context selection as packaging. She envisioned a future in which packaging was almost as big as the content, and just grew around it to protect the required surface area. Of course, we are aware that the product concept needs further elaboration concerning its appropriateness as wine packaging (would the proposed packaging affect the taste of wine?), or consumer acceptance (would it be easily accepted by consumers as intended?). However, we argue that the way in which it is envisioned in terms of the context and the way of use, the application idea illustrates how materials experience thinking can facilitate a novel design idea, bridging the material’s technical and experiential qualities in a unique manner.

In order to expand on our argument further, we picked another example product made of mycelium-based materials. The Mush-Lume collection by Danielle Trofe consists of a series of lampshades grown by using the Ecovative composite GIY package (Figure 15, right). In this example, we see a relatively durable product. Although the designer emphasizes that the material can go back to nature, and biodegrades when it completes its lifetime, the application does not necessarily provide an indication when this would happen, and whether it would happen at all. The material is a surrogate for other materials (e.g., plastics) that can be used in making lampshades. The designer prefers to keep an archetypical form, which cleverly allows an easy connotation with mushroom form. However, the designer does not emphasize a specific experiential quality of the material she would like to bring forward and/or bridge to the product’s utility.

After closely following a growing design process, we are aware that designing with a growing matter and reaching a material proposal that would be viable for commercial applications is challenging for designers. Thus, our aim is not to diminish the value of any particular application or any particular approach followed by designers. Instead, grounded on the particular case we present in this paper, we reflect upon what added values the materials experience thinking, which is made actionable through the MDD method, would bring in such projects.

Conclusions

The present paper explored the journey of a master’s product design student who searched for a product application idea for mycelium-based materials. Our goal was to provide a practical understanding of the material-driven design process when the material grows. Furthermore, we provided a critique on the final outcome of the design effort, in comparison to the existing mycelium-based product applications.

We illustrated that due to the unexpected influences of nature on the material and the unique temporality it has, the student adopted an approach that requires openness to tackle uncertainty. The student embraced what the material had to offer in a serendipitous way. With the intention of structuring the tinkering activities and mapping the findings as a coherent whole, the student also developed a materials taxonomy illustrating what specific variables affect the technical properties and the experiential qualities of the material.

Finding a meaningful product application idea for a material at hand is not straightforward. It requires critical understanding of what the material offers, as to form, function and overall experience. The student followed the Material Driven Design (MDD) Method, which provided a structure and awareness in exploring the material’s technical and experiential qualities, and how these qualities can be bridged in a creative way. The student was particularly inspired by the performative qualities of the material in finding a novel interaction scenario for wine packaging. The case presented in this paper illustrates how materials experience thinking can facilitate a novel design idea, to inspire future Growing Design practices.

The thinking of material and product form concurrently expands the boundaries of design toward new territories asking for new tools and methods, which will be one of our future research endeavours.

Acknowledgments

We would like to thank the group of Professor Han Wösten, in particular Freek Appels, from the department of Microbiology of Utrecht University, and the designer Maurizio Montalti (Officina Corpuscoli) for valuable feedback and guidance for the creation of the mycelium-based materials throughout this project.

References

- Agapakis, C. M. (2013). Designing synthetic biology. ACS Synthetic Biology, 3(3), 121-128.

- Álvarez-Chávez, C. R., Edwards, S., Moure-Eraso, R., & Geiser, K. (2012). Sustainability of bio-based plastics: General comparative analysis and recommendations for improvement. Journal of Cleaner Production, 23(1), 47-56.

- Alves, C., Silva, A. J., Reis, L. G., Freitas, M., Rodrigues, L. B., & Alves, D. E. (2010). Ecodesign of automotive components making use of natural jute fiber composites. Journal of Cleaner Production, 18(4), 313-327.

- Appels, F. V. (2014). Mycelium design (Unpublished master’s thesis). Utrecht University, Utrecht, The Netherlands.

- Ashby, M. F. (2013). Materials and the environment: Eco-informed material choice. Oxford, UK: Butterworth-Heinemann.

- Bader, C., Patrick, W. G., Kolb, D., Hays, S. G., Keating, S., Sharma, S., ... & Oxman, N. (2016). Grown, printed, and biologically augmented: An additively manufactured microfluidic warable, functionally templated for synthetic microbes. 3D Printing and Additive Manufacturing, 3(2), 79-89.

- Barati, B., Karana, E., & Hekkert, P. (2015). A case of designing with an underdeveloped computational composite for materials experience. Proceedings of the International Conference of the DRS Special Interest Group on Experiential Knowledge (EKSIG) (pp. 118-132). Kolding, Denmark: Design School Kolding.

- Barati, B., Karana, E., Jansen, K., & Hekkert, P. (2016). Functional demonstrators to support understanding of smart materials. In Proceedings of the 10th International Conference on Tangible, Embedded, and Embodied Interaction (pp. 386-391). New York, NY: ACM.

- Barati, B., Karana, E., & Foole, M. (2017). ‘Experience prototyping’ smart material composites. Proceedings of International Conference of the DRS Special Interest Group on Experiential Knowledge (EKSIG) (pp. 50-65). Delft, The Netherlands: Delft University of Technology.

- Blauwhoff, D. R. L. M. (2016). Mycelium based materials: A case on material driven design and forecasting acceptance (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.

- Bruner, G. C., & Kumar, A. (2005). Explaining consumer acceptance of handheld Internet devices. Journal of Business Research, 58(5), 553-558.

- Callister, W. D., & Rethwisch, D. G. (2011). Materials science and engineering: An introduction. Hoboken, NJ: John Wiley & Sons.

- Camere, S., & Karana, E. (2017). Growing materials for product design. In Proceedings of the International Conference of the DRS Special Interest Group on Experiential Knowledge and Emerging Materials (pp. 101-115). Delft, The Netherlands: Delft University of Technology.

- Camere, S., & Karana, E. (2018). Fabricating materials from living organisms: An emerging design practice. Journal of Cleaner Production, 186, 570-584.

- Carlile, M. J., Watkinson, S. C., & Gooday, G. W. (1994). The fungi. New York, NY: Elsevier.

- Chen, C. C., & Crilly, N. (2016). Describing complex design practices with a cross-domain framework: Learning from Synthetic Biology and Swarm Robotics. Research in Engineering Design, 27(3), 291-305.

- Chen, L. D., Gillenson, M. L., & Sherrell, D. L. (2002). Enticing online consumers: An extended technology acceptance perspective. Information & Management, 39(8), 705-719.

- Claus, S. (2016). Designing with transparent lighting: A Do-It-Yourself approach (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.

- Ciuffi, V. (2013). Growing design. Abitare Magazine, 531, 108-111.

- Collet, C. (2017). ‘Grow made’ textiles. In Proceedings of the International Conference of the DRS Special Interest Group on Experiential Knowledge and Emerging Materials (pp. 24-37). Delft, The Netherlands: Delft University of Technology.

- Collins, J. (2012). Synthetic biology: Bits and pieces come to life. Nature, 483(7387), S8-S10.

- Congdon, A. (2013). Biological atelier: SS 2082 ‘extinct’ collection. Retrieved January 12, 2017, from http://www.amycongdon.com/biological-atelier-ss-2082-extinct/

- Crabbé, A., Jacobs, R., Van Hoof, V., Bergmans, A., & Van Acker, K. (2013). Transition towards sustainable material innovation: Evidence and evaluation of the Flemish case. Journal of Cleaner Production, 56, 63-72.

- Creusen, M. E., & Schoormans, J. P. (2005). The different roles of product appearance in consumer choice. Journal of Product Innovation Management, 22(1), 63-81.

- Daalhuizen, J., Badke-Schaub, P., & Batill, S. (2009). Dealing with uncertainty in design practice: Issues for designer-centered methodology. Retrieved from http://orbit.dtu.dk/files/87524494/ds58_9_147.pdf

- Dade-Robertson, M., Figueroa, C. R., & Zhang, M. (2015). Material ecologies for synthetic biology: Biomineralization and the state space of design. Computer-Aided Design, 60, 28-39.

- Davis, F. D. (1989). Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Quarterly, 13(3), 319-340.

- Deacon, J. W. (1980). Introduction to modern mycology. Oxford, UK: Blackwell.

- Dunne, A., & Raby, F. (2013). Speculative everything: Design, fiction, and social dreaming. Cambridge, MA: MIT.

- Geiser, K. (2001). Materials matter: Towards a sustainable materials policy first. Cambridge, MA: MIT Press.

- Ghazal, S. (2016). Plastic bakery: A new taste for plastic waste (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.

- Giaccardi, E., & Karana, E. (2015). Foundations of materials experience: An approach for HCI. In Proceedings of the 33rd Conference on Human Factors in Computing Systems (pp. 2447-2456). New York, NY: ACM.

- Ginsberg, A. D., Calvert, J., Schyfter, P., Elfick, A., & Endy, D. (2014). Synthetic aesthetics: Investigating synthetic biology’s designs on nature. Cambridge, MA: MIT.

- Haider, A., & Eder, A., (2010). Markets, applications, and processes for wood polymer composites (WPC) in Europe. In Proceedings of the 1st International Conference on Processing Technologies for the Forest and Biobased Product Industries (pp. 146-151). Kuchl, Austria: Salzburg University of Applied Sciences.

- Haneef, M., Ceseracciu, L., Canale, C., Bayer, I. S., Heredia-Guerrero, J. A., & Athanassiou, A. (2017). Advanced materials from fungal mycelium: Fabrication and tuning of physical properties. Retrieved from https://www.nature.com/articles/srep41292

- Hekkert, P., Snelders, D., & Wieringen, P. C. (2003). ‘Most advanced, yet acceptable’: Typicality and novelty as joint predictors of aesthetic preference in industrial design. British Journal of Psychology, 94(1), 111-124.

- Holt, G. A., Mcintyre, G., Flagg, D., Bayer, E., Wanjura, J. D., & Pelletier, M. G. (2012). Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. Journal of Biobased Materials and Bioenergy, 6(4), 431-439.

- Hung, W. K., & Chen, L. L. (2012). Effects of novelty and its dimensions on aesthetic preference in product design. International Journal of Design, 6(2), 81-90.

- Jiang, L., Walczyk, D., Mooney, L., & Putney, S. (2013). Manufacturing of mycelium-based biocomposites. In Proceedings of the International SAMPE Technical Conference (pp. 1944-1955). Diamond Bar, CA: Society for the Advancement of Material and Process Engineering.

- Jiang, L., Walczyk, D., McIntyre, G., & Bucinell, R. (2016). A new approach to manufacturing biocomposite sandwich structures: Mycelium-based cores. In Proceedings of the 11th International Conference on Manufacturing Science and Engineering (No. V001T02A025). New York, NY: American Society of Mechanical Engineers.

- Jones, M., Huynh, T., Dekiwadia, C., Daver, F., & John, S. (2017). Mycelium composites: A review of engineering characteristics and growth kinetics. Journal of Bionanoscience, 11(4), 241-257.

- Karana, E. (2009). Meanings of materials (Doctoral dissertation). Delft University of Technology, Delft, The Netherlands.

- Karana, E., Barati, B., Rognoli, V., & Zeeuw Van Der Laan, A., (2015). Material driven design (MDD): A method to design for material experiences. International Journal of Design, 9(2), 35-54.

- Kavanagh, K. (Ed.) (2011). Fungi: Biology and applications. Hoboken, NJ: Wiley-Blackwell.

- Krishnan, V., & Bhattacharya, S. (2002). Technology selection and commitment in new product development: The role of uncertainty and design flexibility. Management Science 48(3), 313-327.

- Lakoff, G. (1987). Women, fire, and dangerous things. Chicago, IL: University of Chicago.

- Lindberg, S. M., Béland, M. C., Edström, K., Granberg, H., & Berthold, F. (2016). Towards a cellulose-based society: Demonstrating the feasibility of new bio-based material concepts and products. In Proceedings of the 10th International Conference on Design and Emotion (pp. 411-419). Amsterdam, The Netherland: The Design & Emotion Society.

- Loken, B., & Ward, J. (1990). Alternative approaches to understanding the determinants of typicality. Journal of Consumer Research, 17(2), 111-126.

- Lunceford, B. (2009). Reconsidering technology adoption and resistance: Observations of a semi-Luddite. Explorations in Media Ecology, 8(1), 29-47.

- Lussenburg, K. M. (2014). Designing (with) 3D printed textiles (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.

- Madigan, M. T., Martinko, J. M., & Parker, J. (1997). Brock biology of microorganisms. Upper Saddle River, NJ: Prentice Hall.

- Majumdar, P., Karana, E., Sonneveld, M. H., Giaccardi, E., Nimkulrat, N., Niedderer, K., & Camere, S. (2017). The Plastic Bakery: A Case of Material Driven Design. In Proceedings of the International Conference of the DRS Special Interest Group on Experiential Knowledge and Emerging Materials (pp. 116-128). Delft, The Netherlands: Delft University of Technology.

- Martindale, C., Moore, K., & Borkum, J. (1990). Aesthetic preference: Anomalous findings of Berlyne’s psychobiological theory. American Journal of Psychology, 103(1), 53-80.

- Mironov, V., Trusk, T., Kasyanov, V., Little, S., Swaja, R., & Markwald, R. (2009). Biofabrication: A 21st century manufacturing paradigm. Biofabrication, 1(2), 1-14.

- Montalti, M., (2010). The growing lab. Retrieved from http://www.corpuscoli.com/projects/the-growing-lab/

- Moore, D. (2002). Fungal morphogenesis (Vol. 35). Cambridge, UK: Cambridge University.

- Moore, G. C., & Benbasat, I. (1996). Integrating diffusion of innovations and theory of reasoned action models to predict utilization of information technology by end-users. In Diffusion and adoption of information technology (pp. 132-146). Springer, Boston, MA.

- Morel, K. (2000). Consumer’s reactions to ambiguous product information (Unpublished doctoral dissertation). Delft University of Technology, Delft, The Netherlands.

- Myers, W. (2012). BioDesign: Nature, science, creativity. New York, NY: Moma.

- Myers, W., & Antonelli, P. (2012). BioDesign: Nature, science, creativity. New York, NY: Moma.

- Oskam, I., de Jong, M., Lepelaar, M., Nackenhorst, K., Boerema, M., … Agrawal, P. (2017). Recurf: Hergebruik van textile in biocomposieten: Van materiaal tot toepassing [Recurf: Reuse of textiles in bio composites: From material to application]. Amsterdam, The Netherlands: Kenniscentrum Techniek, Hogeschool van Amsterdam.

- Papacharissi, Z., & Rubin, A. M. (2000). Predictors of Internet use. Journal of Broadcasting & Electronic Media, 44(2), 175-196.

- Parisi, S., Rognoli, V., & Ayala Garcia, C. (2016). Designing materials experiences through passing of time: Material driven design method applied to mycelium-based composites. In Proceedings of the 10th International Conference on Design and Emotion (pp. 239-255). Amsterdam, The Netherlands: The Design and Emotion Society.

- Parkes, A., & Dickie, C. (2013). A biological imperative for interaction design. In Proceedings of the Conference on Human Factors in Computing Systems (Extended Abstracts, pp. 2209-2218). New York, NY: ACM.

- Pelkmans, J. F., Lugones, L. G., & Wösten, H. A. (2016). Fruiting body formation in basidiomycetes. In J. Wendland (Ed.), Growth, differentiation and sexuality, (pp. 387-405). Berlin, Germany: Springer.

- Ribul, M. (2016). Recepies for material activism. Retrieved from https://issuu.com/miriamribul/docs/miriam_ribul_recipes_for_material_a/33

- Rogers, E. M. (1995). Diffusion of innovations. New York, NY: Free Press.

- Rognoli, V., Bianchini, M., Maffei, S., & Karana, E. (2015). DIY materials. The Journal of Materials and Design, 86, 692-702.

- Shah, V., Nojin Kwak, R., & Lance Holbert, D. (2001). “Connecting” and “disconnecting” with civic life: Patterns of Internet use and the production of social capital. Political Communication, 18(2), 141-162.

- Solomon, M. R., Bamossy, G. J., Askegaard, S., & Hogg, M. K. (2006). Consumer behaviour: A European perspective. Upper Saddle River, NJ: Prentice Hall.

- Song, I., Larose, R., Eastin, M. S., & Lin, C. A. (2004). Internet gratifications and Internet addiction: On the uses and abuses of new media. CyberPsychology & Behavior, 7(4), 384-394.

- Taylor, S., & Todd, P. A. (1995). Understanding information technology usage: A test of competing models. Information Systems Research, 6(2), 144-176.

- Tornatzky, L. G., & Klein, K. J. (1982). Innovation characteristics and innovation adoption-implementation: A meta-analysis of findings. IEEE Transactions on Engineering Management, 29(1), 28-45.

- Van den Dool, A. C. (2016). From waste to value: Designing with recycled mattress ticking (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.

- Venkatesh, V., & Davis, F. D. (2000). A theoretical extension of the technology acceptance model: Four longitudinal field studies. Management Science, 46(2), 186-204.

- Veelaert, L., Du Bois, E., Hubo, S., Van Kets, K., & Ragaert, K. (2017). Designing from Recycling. In Proceedings of the International Conference of the DRS Special Interest Group on Experiential Knowledge and Emerging Materials (pp. 129-143). Delft, The Netherlands: Delft University of Technology.

- Veryzer, R. W., & Hutchinson, J. W. (1998). The influence of unity and prototypicality on aesthetic responses to new product designs. Journal of Consumer Research, 24(4), 374-394.

- Wainwright, M. (1992). An introduction to fungal biotechnology. Hoboken, NJ: John Wiley & Sons.

- Yang, Z., Zhang, F., Still, B., White, M., & Amstislavski, P. (2017). Physical and mechanical properties of fungal mycelium-based biofoam. Journal of Materials in Civil Engineering, 29(7). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001866

- Zajonc, R. B., & Markus, H. (1982). Affective and cognitive factors in preferences. Journal of Consumer Research, 9(2), 123-131.

- Zeeuw van der Laan, A. (2013). Characterisation of waste coffee grounds as a design material: A case study of material driven design (Unpublished master’s thesis). Delft University of Technology, Delft, The Netherlands.