The Design Innovation Spectrum: An Overview of Design Influences on Innovation for Manufacturing Companies

Jea Hoo Na 1,*, Youngok Choi 2, and David Harrison 2

1 Manchester School of Art, Manchester Metropolitan University, Manchester, UK

2 College of Engineering, Design and Physical Sciences, Brunel University London, London, UK

This paper discusses the expanding parameters of design and innovation, and constructs a design innovation spectrum—a framework presenting a holistic overview of design influences on innovation, in order to comprehend, assess, and prioritise the areas of improvement to increase the innovativeness of manufacturing companies. The research considers manufacturing industry because re-establishing manufacturing strength is a key agenda for balanced economic growth and stability, especially in advanced countries. This empirical research adopted a triangulation approach that included a literature review to construct a theoretical design innovation spectrum, which was then evaluated through in-depth interviews by eleven design innovation and manufacturing experts to link theories and practicality, and forty-six case studies of manufacturing companies to understand its practical implications. The identified design areas were designing, design strategy, and corporate-level design thinking, which were aligned with the parameters of innovation including technological, product/service, process, and organisational innovation to create a design innovation spectrum, which allows for overall assessment of design innovation capabilities, to be used by both internal and/or external design supporting teams to improve manufacturing companies’ innovativeness through design.

Keywords — Design Innovation, Design Innovation Spectrum, Improving Innovativeness, Manufacturing.

Relevance to Design Practice — The design innovation spectrum was developed from this research to contribute to profit (consultancies) and non-profit (governmental and non-governmental) organisations supporting manufacturing companies, by providing a holistic map of design influences on innovation to encourage the use of extensive areas of design to increase various forms of innovation to enhance global competitiveness.

Citation: Na, J., Choi, Y., & Harrison, D. (2017). The design innovation spectrum: An overview of design influences on innovation for manufacturing companies. International Journal of Design, 11(2), 13-24.

Received December 16, 2016; Accepted May 13, 2017; Published August 31, 2017.

Copyright: © 2017 Na, Choi, and Harrison. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: jeahoona@gmail.com

Jea Hoo Na is a Research Associate at Manchester School of Art, Manchester Metropolitan University. He earned his PhD in Design Innovation at Brunel University London with a comprehensive study of design innovation framework for manufacturing companies in the UK. His main research interests have been on the understanding full spectrum of design for innovation in both commercial and social context. He has extensive experiences on commercial and academic projects in design innovation, user insights, and social design with Samsung, LG, Nokia, Transport for London (TfL), Korea Evaluation Institute of Industrial Technology (KEIT), Brunel University London, and University of Birmingham.

Youngok Choi is a senior lecturer in the College of Engineering, Design and Physical Sciences at Brunel University London. Her research interests encompass the role of design in economic growth and improving the quality of people’s lives, and hence sustainable development. The strategic use of design underpins much of her research activities. She has been involved in many design research projects involving design policy and strategy, the social value of design, design for education, and social innovation. She has also worked on projects with industry partners, including Samsung.

David Harrison has a BSc in engineering science and a PhD in robotics. He is a chartered engineer, a member of the IET (Institution of Engineering and Technology), and a fellow of the Higher Education Academy. Harrison is also a professor in the department of design at Brunel University London, and has research interests in sustainable design and innovative approaches to electronic manufacturing. He has developed, patented, and successfully licensed a number of new manufacturing processes in printed electronics.

Introduction

The role of design in businesses has expanded over the years: no longer simply about enhancing aesthetics and functionalities, it now makes a critical contribution to fostering organisations’ innovation, to enable companies to increase their competitiveness (Blaich, 1988; Brown, 2009; Fraser, 2009; Gemser, 1997; Gorb, 1986; Mozota, 1990; Neumeier, 2008; Press & Cooper, 2003; Swann & Birke, 2005; Trueman & Jobber, 1998). The influence of design for innovation can be described as a creative process: its outcome enables a company to increase innovativeness by using the full spectrum of design, including designing (action to create a product), design strategy (management of the design process), and corporate-level design thinking (the philosophy and method of design applied to business management). This is crucial in any organisation as it demonstrates design’s contribution to the extensive areas of innovation where innovation is still an important agenda for top-level managers in companies around the world (Boston Consulting Group, 2014; PricewaterhouseCoopers [PwC], 2014), and is considered an essential element for a successful company (Department of Trade and Industry [DTI], 2006; Hansen & Birkinshaw, 2007; Jolly, 2010; Love, Roper, & Du, 2009; PwC, 2013a; Tucker, 2001).

In this research, the extensive role of design and its influences on innovation are studied in a context of manufacturing because of the decline of industry despite its significant contribution for economic growth and raising living standards (Manyika et al., 2012). The economic trend of the world’s seven major advanced economies (G7)—Canada, France, Germany, Italy, Japan, the United States, and the UK—shows an increased proportion of gross domestic product (GDP) for service industries compared with manufacturing industry. This change in composition is most noticeable in the UK where the GDP share of manufacturing was the highest among the G7 in 1948 (36% normal gross value added—GVA) but the lowest in 2013 with only 10% normal GVA (Banks, Hamroush, Taylor, & Hardie, 2014). The consequences of this economic imbalance were most noticeable during the 2008 global economic downturn which showed how the overreliance on service industries can cause great instability in a nation’s economy, and demonstrated how manufacturing can contribute towards stabilising and balancing the economy (EEF, 2009; Prest, 2008; PwC, 2009; Temple, 2011). The UK government is therefore becoming increasingly aware of the importance of manufacturing industry for UK economic growth and competitiveness (Department for Business Innovation and Skills [BIS], 2010b) and innovation in manufacturing has become an increasingly important development area for both the UK government and industry (BIS, 2011; PwC, 2013b). This paper uses UK manufacturing companies as a case study of advanced countries—and perhaps developing countries—which have in the past used manufacturing to boost their economic competitiveness but are now experiencing a shift in focus to other industries, including services, to show how design innovation can help increase innovativeness in manufacturing companies to gain global competitiveness and enhance national economy.

The contribution of design for manufacturing companies to increase innovativeness is therefore an important agenda. However, despite the interlinking relationships between design and innovation the wider spectrum of design—including at the operational level (the action of designing products/services), strategic level (the methodological processes), and corporate level (the philosophical principle) of business—is sparsely used in UK manufacturing companies (Cox, 2005; Dumas & Whitfield, 1989; Livesey & Moultrie, 2009; Na & Choi, 2012). This is partly because of the marginalisation of design in innovation (Cumming, 1998; Freel, 2000; OECD/Eurostat, 2005) and the generalisation of innovation in design studies (Gemser, Candi, & Ende, 2011; Visser, 2009). These researches express the importance of design and innovation, but without a comprehensive integration of different areas of design (designing, design strategy, and corporate-level design thinking) and innovation (technological, product, service, process, and organisational innovation). This can cause confusion for companies seeking to improve a particular type or area of innovation but with limited knowledge of the broader design spectrum. This can also lead to increased ‘fuzziness’ of the importance of design for innovation, which is particularly problematic when attempting to convince manufacturing companies about the extensive benefits of design to increase innovativeness (Le Masson, Benoit, & Hatchuel, 2010). Research questions arise from these observations: (i) what are the parameters of design and innovation? (ii) how are the design and innovation areas linked? and (iii) how can all areas of design be implemented in manufacturing companies? This paper therefore aims to create a design innovation spectrum by presenting a holistic overview of design influences on innovation, in order to comprehend, assess, and prioritise the areas of improvement to increase the innovativeness of manufacturing companies. It is anticipated that the design innovation spectrum will be used as a framework for further developing an audit tool which can help manufacturing companies demystify design, and encourage the use of the various areas of design to enhance innovativeness to increase global competitiveness.

The Research Methodology

The research included five key stages. Firstly, an investigative study was conducted into the meaning and capabilities of design, using a literature review and subsequent content analysis method to create a theory-based Design Spectrum, which laid a foundation to demonstrate the wide breath of design parameters. The second stage was an exploration of the expanding parameters of innovation in the commercial environment. A literature review was also conducted at this stage, where the theory-based Innovation Spectrum was created to synthesise different theories of innovation to provide an overview of innovation in a company. Further exploration then took place into the relationship between design and innovation, to identify the link between the two, and create the theoretical Design Innovation Spectrum. In the third stage of the research, the theoretical design innovation spectrum was evaluated by eleven experts, and further exploration of the practical application was conducted. The research used a face-to-face semi-structured interview method, using purposive sampling to select expert interviewees with at least twenty years’ experience of working for or with UK manufacturing companies, to ensure reliable opinions from the representative sectors.

The expert interviewees’ evaluation was a qualitative enquiry, intended to identify the effectiveness of the phenomenon under study (Patton, 2001). The interview stakeholders consisted of three groups including a first group of five design practitioners (DP1-DP5): directors of industrial and product design consultancies with considerable experience of turning technological ideas into feasible products. The second stakeholder group was a design organisation which supports manufacturing companies to use design more effectively in the UK, including a Head of Design and two design advisors (DO1-DO3). The third group consisted of the lead technologist, the head of development, and the design advisor of a manufacturing organisation (MO1-MO3) which supports the realisation of technology in UK manufacturing. The interview topics included: (i) comprehensiveness of the design innovation spectrum and how to improve the spectrum, (ii) increasing acceptance of all the areas of the spectrum in manufacturing companies, (iii) use of design audit tool(s) in practice and how to increase design audit usage. The data collected from the interviews was analysed using a content analysis (open coding) method where the key discussion topics were adopted as the major themes of the analysis.

In the fourth stage of the research, a case study of forty-six manufacturing companies was used to identify the link between the design innovation spectrum and its practical implications. In order to select the cases, winners of four innovation awards were examined: two design-oriented (Design Management Europe Awards, dba Design Effectiveness Awards), and two innovation-based (Queen’s Awards for Enterprise-innovation, The Manufacturer MX Awards). The awards were chosen for their rigorous judging criteria and recognisability among design and manufacturing professionals and academics. The explicit data collection yielded systematic categorisation of the data from various sources. In order to understand the data in the study’s context (i.e., a design innovation spectrum), an ethnographic content analysis was used as it is a highly interactive way of analysing data from various sources including news articles, book, magazines, newspapers, and searching for context, underlying meanings, patterns, and processes (Altheide, 1987). Following the interviews, the fifth and final stage of the research analysed and synthesised the data, to create the final Design Innovation Spectrum and recommend its practical implications to enhance the innovativeness of manufacturing companies.

The key stages of this research correspond to the research questions mentioned in the introduction. In the first and second stage, the research question ‘what are the parameters of design and innovation?’ was answered. The third and fourth stages of the research answer the second and third research question: ‘how are the design and innovation areas linked?’, and ‘how can all areas of design be implemented in manufacturing companies?’

The Design Spectrum: The Theoretical Parameters of Design

The design spectrum is created in an attempt to understand the wider contribution of design in business in an accessible form. The word ‘design’ is both a noun and a verb (Bruce & Bessant, 2002; British Standards Institution, 2008; Cooper & Junginger, 2009). The noun often refers to both tangible and intangible artificial outputs created by specific design disciplines: engineering design, product design, fashion design, graphic design, and service design, etc., (Best, 2006; Bruce & Bessant, 2002; Cooper & Press, 1995). The verb ‘design’ usually describes a cognitive activity which improves a situation (Simon, 1996; Verganti, 2009; Visser, 2009). It is also described by a C-K theory where C represents concepts and K describes knowledge, where design is a systematic expansion of concept that simultaneously uses and creates knowledge (Hatchuel & Weil, 2003; Le Masson et al., 2010). This research considers the design in the widest possible sense to construct the Design Spectrum. The three key elements identified through the literature review were: designing (action to create a product), design strategy (management of the design process), and corporate-level design thinking (the philosophy and method of design applied to business management). These elements pertain to both determinacy and indeterminacy in design thinking (Buchanan, 1992) where design seeks to solve predetermined problems but also transforms ‘wicked’ problems into viable opportunities (BIS, 2010a), therefore balancing analytical and intuitive thinking (Martin, 2009) in the commercial context.

The ‘designing’ (for production) is defined as a company’s activity to create an artefact, including design for manufacture and engineering design (Boothroyd, Dewhurst, & Knight, 2002; Lindbeck, 1995; Poli, 2001). According to UK manufacturing companies, this is the main activity of design (Livesey & Moultrie, 2009; Na & Choi, 2012), and is conducted by professional designers and design engineers, taking into consideration function, aesthetics, ease of manufacture, etc., which involve technical ability to manipulate ideas with appropriate materials, colours, textures, shapes, etc., (Best, 2006; Livesey & Moultrie, 2009; Tether, 2005). Moreover, the ‘designing’ (for process/image) is also an activity which creates intangible outcomes: services, brands, and customer experiences. Designing often influences all levels of the business operation as its impact can have profound influences on the success of the business (Pugh, 1996); however, due to the nature of the work, designing can be placed in the ‘activity level’ of a company, in Needle’s (2010) model of business context. This level of an organisation includes function groups for innovation, operation, marketing, human resource management, and finance and accounting, all interlinked and influenced by each other, which also influence the business context itself.

The business context model also includes the ‘strategic level’ and the ‘organisational level’ of a company (Needle, 2010). The strategic level includes management decisions which determine business activities, including the range of products and services, marketing budgets, resource management, and employees. Design strategy operates at the strategic level, dealing with the management of design in a firm, usually conducted by design mangers and/or senior managers, which is considered important for business success (Best, 2006; Cox, 2005; Design Council [DC], 2008, 2010; Dumas & Whitfield, 1989; Fernández-Mesa, Alegre-Vidal, Chiva-Gómez, & Antonio Gutiérrez-Gracia, 2013; Tether, 2009). Further to the development of design strategy, design’s capability in the wider context of a company is also considered. Recently described as ‘design thinking’, it is concerned with how the design principle can be used in making businesses deal with both the rapid complex changes organisations face in the modern market and as a set of tools or a method for designers to better comprehend feasibility, viability, and desirability (Brown, 2009; Liedtka & Ogilvie, 2011; Martin, 2009; Mootee, 2013) with the emphasis that the CEOs must be “designers”, referring to design thinking as a management methodology (Nussbaum, 2007), and the importance of the business leader’s appreciation of design to ensure a firm’s success (DC, 2014). It is appropriate to place this at organisational level as it is concerned with goals, structure, ownership, and organisational or corporate culture. For the purpose of this research, it will be called ‘corporate-level design thinking’ to distinguish it from the design thinking commonly practised by designers to produce tangible outcomes (designing).

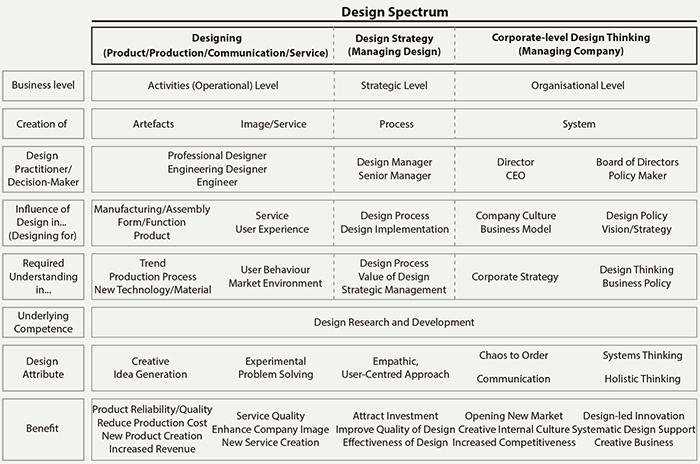

A theoretical design spectrum has been created through a synthesis of the key elements of design in the literature, with input from various design academics (see Figure 1, which shows the design areas on the top row of the diagram). The literature also indicates that design does not necessarily function as a progression of different levels, i.e., it does not need one area to be achieved in order to acquire other areas. It is difficult to distinguish the presence of design binomially. Sometimes, a company has a stronger presence in one design area and a weaker presence in another. Moreover, as the distinction between design areas is hard to establish as they are closely linked, dotted lines are used to describe this loose distinction: a phenomenon best described as a spectrum.

Figure 1. Theoretical model of the design spectrum with key terminologies to describe its context in business.

The design spectrum attributes listed in the left column in Figure 1 are derived from various literatures to best describe the areas of the spectrum. Although they are sometimes hard to distinguish, some general patterns emerged from the literature. The ‘business level’ described earlier indicates the possible place of design in the context of an organisation, and ‘creation of’ indicates the possible outcome or improvements through using design. ‘System’ is mentioned in some literatures (Best, 2006; Brown, 2009; Clark & Smith, 2008; Gorb, 1986; Visser, 2009) in the context of the company as whole, not just as a system for a specific product or service (Boothroyd et al., 2002; Bruce & Bessant, 2002). The ‘design practitioner/decision-maker’ describes the people in an organisation who are most likely to be directly responsible for particular areas; similarly ‘influence of design in... (designing for)’ indicates the functions and context of a business which these design decisions will influence. Furthermore, ‘required understanding in...’ describes areas of knowledge and awareness required to make appropriate decisions. These areas of understanding are not exclusive to professionals of particular design areas, e.g., a good understanding of trends, production processes, user behaviour, etc., which are in the ‘designing’ area of the spectrum, but are also required by company directors. However, the separation indicates that these areas of understanding are essential for ‘designing’ a good product/service and user experience, just as understanding corporate strategy, design thinking, and business policy are essential in corporate-level design thinking. Similarly, ‘underlying competence’, ‘design attribute’ and ‘benefit’ are even harder to separate, so the dotted lines are removed from these attributes of the design spectrum.

The Innovation Spectrum: The Theoretical Parameters of Innovation

The importance of innovation is emphasised in almost all socio-economic areas, ranging from business and management, economics, organisation studies, innovation and entrepreneurship, technology, science and engineering, knowledge management, and marketing (Baregheh, Rowley, & Sambrook, 2009). They describe innovation as a multi-stage organisational process which transforms ideas into new/improved products, service, or processes to advance, compete, and differentiate in an appropriate market. Innovation, like design, has several areas of emphasis depending on where the most important ‘change’ for a company lies. One of the simpler principles of innovation is described by the Department of Trade and Industry (DTI), (now part of the Department of Business, Innovation & Skills [BIS]) as “the successful exploitation of new ideas” (DTI, 2003, p. 8). This brief powerful description, still widely used by the UK government, is seen in the manufacturing sector as a way to compete in the globalised market (BIS, 2010c). Moreover, the innovation process has been evolving: Rothwell describes four generations of innovation model, where a linear process of technology push or market pull has evolved into a more flexible integrated process (Rothwell, 1994).

The parameters of innovation have widened in a way similar to design. Innovation was often seen as product or service breakthroughs, whether radical or incremental changes, especially in the UK manufacturing sector. However, Nesta emphasises the importance of ‘hidden innovation’ in order to compete globally and not remain locked-in to existing technologies and business models (Harris & Cox, 2008). Nesta calls this ‘Total Innovation’, which includes new organisational structures and business models using existing technologies and beyond (Hidden Innovation Type II), and micro-innovations which are developed locally and in small scale, often outside of R&D programmes which is hard to measure by conventional indicators (Hidden Innovation Type IV). This is further emphasised by the OECD/Eurostat (2005) which describes innovation types as product, process, marketing, and organisation; similarly, Nesta describes an Innovation Value Chain: accessing knowledge, building innovation, and commercialising innovation (Roper, Hales, Bryson, & Love, 2009). Keeley et. al. (2013) apportioned this further with Ten Types of Innovation: profit model, network, structure, process, product performance, product system, service, channel, brand, and customer engagement for an organisation. However, the acknowledgement of broader innovation parameters has been slow to filter through to UK manufacturing firms where technological innovation is still the predominant interpretation of innovation (Na & Choi, 2012; Westlake, MacAulay, Gratzke, Bravo-Biosca, & Bakhshi, 2009). This is not surprising, especially in high-value manufacturing where technology push is an important competitive advantage for them to compete in the global market (PwC, 2009; TSB, 2012b). However, as Nesta suggests, embracing other areas of innovation is an increasingly important agenda as technological innovation is now sought by emerging economies such as China and India (Harris & Cox, 2008).

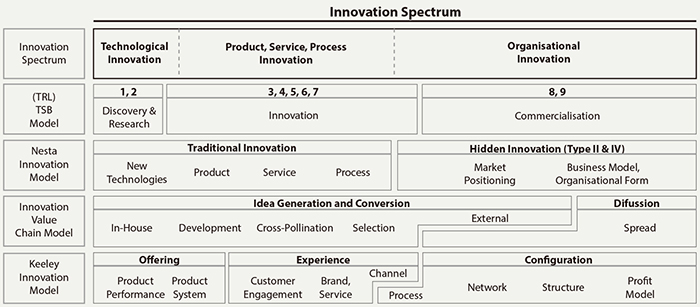

In order to more easily comprehend the various areas of innovation, an overview was created to enable better understanding of the parameters of innovation within a company. The innovation spectrum was thus created, which contains the various theories of innovation including, but not limited to, the Technology readiness level (TRL) related innovation model by Technology Strategy Board (TSB, 2012a) for its relevance in the manufacturing sector; the Innovation Value Chain (Hansen & Birkinshaw, 2007) and ‘Total Innovation’ (Roper et al., 2009) for its overall perspective on innovation in both theoretical and government level perspectives; and Ten Types of Innovation (Keeley et al., 2013) for its practical implication for businesses with a plethora of case studies easily recognisable in the commercial context. The main areas of the innovation spectrum were found to be technological, product/service, process, and organisational innovation, which are strongly interlinked. However, for the purpose of the in-depth study, it was necessary to separate these areas. According to Nesta’s total innovation theory (Harris & Cox, 2008), these innovation areas can be categorised as traditional innovation, which concurs with the more manufacturing-oriented theories of innovation (Laforet & Tann, 2006; Mosey, Clare, & Woodcock, 2002), whereas organisational innovation includes what Nesta calls ‘hidden innovations’, and other theories which deal with the broader perspectives of innovation in an organisation (Berkhout, Hartmann, Duin, & Ortt, 2006; Utterback, 1986; West & Anderson, 1996). Some models, including the Innovation Value Chain and Ten Types of Innovation, were de-constructed to best fit in the innovation spectrum (see Figure 2).

Figure 2. Theoretical model of the innovation spectrum to illustrate the parameters of innovation within a company.

The Design Innovation Spectrum: The Relationship between Design and Innovation

The relationship between design and innovation can be found in many literatures. However, the scope of design and innovation varies and the association also differs depending on the literature. The research found three main ways in which design is related to innovation. Firstly, it provides a ‘symbolic representation’ as a vision for innovation (Swann & Birke, 2005), which is closely linked to design’s capacity to visualise ideas. Secondly, it creates greater meaning for the innovative products and services it delivers (Trueman & Jobber, 1998; Verganti, 2009). Lastly, it underpins how a company, as a whole, creates and maintains innovation itself from operational and strategic management (DC, 2014; Mozota, 2003). An important ingredient of all of the listed associations between design and innovation is design’s ability to manipulate and visualise creativity to solve an organisation’s complex or ‘wicked’ problems at different levels of the organisation. A DTI (2005) report illustrated this, describing design as a bridge between scientific knowledge and new technology to produce a usable end product, emphasising that it links creativity and innovation. However, in this report, design is still seen as activities within a business: including the disciplines of graphic, interior, fashion, industrial, and engineering design. When design is seen as an activity (i.e., on the left side of the design spectrum,) it is inevitable that design will only be in one portion of the Innovation Spectrum (Figure 2) rather than having holistic influences on all areas of innovation.

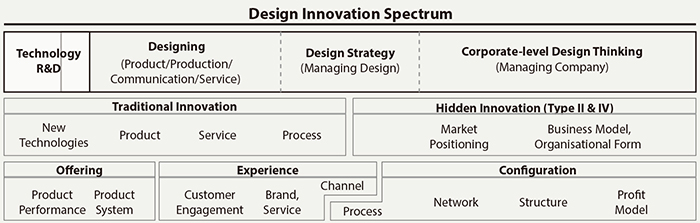

Cox (2005) adopted the influence of design in the broader innovation spectrum. He refered to the Third Community Innovation Survey to illustrate that design expense can indeed generate greater innovation impact in i) an increased range of goods/services, ii) improved quality of goods/services, iii) open new markets/increase the market share, iv) improved production flexibility, v) reduced unit labour costs, and vi) reduce materials and/or energy use. Furthermore, design’s influence can be seen across various areas of manufacturing small and medium-sized enterprises (SMEs) and, as Tether (2009) described, firms using design in both products and services are more likely to produce good products and process innovation, although his reference to design was more about explicit design (towards the left side of the design spectrum) rather than ‘hidden’ design (towards the right side of the design spectrum). Design parameters in these reports concentrate on confining design in a form which is regarded as a part of the firm’s activity. This is not surprising since it is more manageable to measure than that of corporate-level design thinking. However, a theory from Verganti (2009) elaborated design further by recognising that it can change the meaning of an object, and furthermore of the company producing that object. Although he saw innovation in relation to technology, this view of design influence demonstrates the importance of design in relation to innovation in a wider perspective. Mozota (2003) expanded this further, taking design to corporate-level, where it can influence changes in the vision and strategy of a company itself, which is where innovation is also seen as an essential part of success. The latest design thinking theories also discuss design at corporate-level and include design influences for organisational innovation (Bertola & Teixeira, 2003), but it becomes much harder at this point to distinguish and measure design input in an organisation. However, when the parameters of design and innovation are regarded as having an influence on the whole organisation (as shown in Figures 1 and 2), it is theoretically possible to overlay them with regard to their positions in organisational levels and relative capabilities. This convergence between design and innovation provides a comprehensive overview of design capabilities which are likely to influence innovation in particular areas and levels of business (see Figure 3).

Figure 3. Theoretical model of the design innovation spectrum.

Evaluation and Finalisation of the Design Innovation Spectrum

Evaluation of the design innovation spectrum by the design innovation experts revealed that it was comprehensive enough to show most of the influences and roles of design within a firm. This was especially apparent with the design practitioner (DP) and design organisation (DO) groups where all agreed that ‘corporate-level design thinking’ is a positive inclusion in the spectrum, to demonstrate the importance of design in business management. The manufacturing organization (MO) group also recognised the design innovation spectrum as a good approach to address the ‘fuzziness’ of the term ‘design’ in manufacturing companies. However, the MO group and some interviewees from the DP and DO groups (interviewees DP1 and DO2) also recognised that including all the areas of design in the spectrum could lead to confusion about what design signifies for a company. They also noted that it could be overwhelming for manufacturers with little knowledge of, or perhaps little interest in, design to relate to all the areas of design, especially towards the right-hand side of the spectrum (MO1, DP2, 4, and DO2). This observation reflects the limited recognition of design by manufacturing companies discussed earlier in the paper, and explains why the link between design and innovation in the design innovation spectrum is important, as it attempts to illustrate the relevance of the expanding role of design to ‘total innovation’, with which manufacturing companies are more familiar.

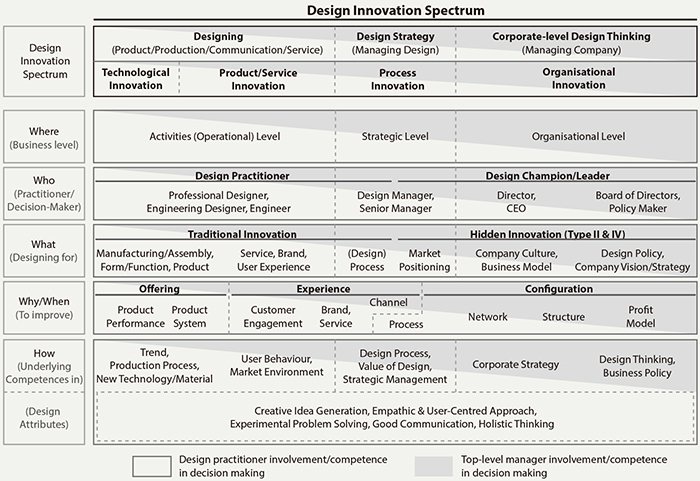

Some interviewees misinterpreted the Design Innovation Spectrum, their confusion arising mainly from over-simplification of the spectrum. Firstly, most interviewees saw the spectrum as a process from left to right; this was unintentional as it is constructed to show the parameters of Design Innovation for different levels of a whole business, not as a process a company must go through to achieve better innovation. This confusion, arising from unclear representation, was addressed by including areas of decision-making influences by design practitioners (white) and top managers (grey) (see Figure 4), which also addressed the issue of representing the amount of involvement in each design innovation attribute by the people in an organisation (DP2, DP3, DP5, DO2, and DO3). For example, in the ‘Where (Business level)’ attribute, the design practitioner’s involvement is more at an activity level, whereas the top manager’s involvement is more at an organisational level. Furthermore, although interviewees DP1, DP2, and MO2 suggested that the spectrum itself should be visually simpler to give immediate effect to an appropriate audience, the majority of the interviewees found it difficult to easily associate the attributes of the Design Spectrum (Figure 1) and the Innovation Spectrum (Figure 2) in the theoretical Design Innovation Spectrum (Figure 3), where they are omitted to give a simpler visual representation. Some details were therefore presented in the improved Design Innovation Spectrum (Figure 4). The spectrum attributions also used a more recognisable analogy (Kipling method), in response to a suggestion from interviewees DP1, DP4, DP5, and MO3.

Figure 4. Design innovation spectrum with improvements suggested by the experts in design and manufacturing.

The DP and MO groups made some contradictory comments: the MO group all agreed that design has little or no effect on technology R&D in a pure science form (TRL 1-2). However, interviewees DP2 and DP3 commented that design should touch on this, even in this early stage of innovation, not as a new product development tool per se, but as a way to (i) understand the needs to consider which areas of R&D are required by understanding current trends, new technologies/materials, user behaviour, and market environments as described in the ‘designing’ area, and (ii) develop a company culture or environment which values creativity in the technology development by using design thinking principles to encourage experimental problem solving and creative idea generation as described in the ‘corporate-level design thinking’ area of the design innovation spectrum. Nonetheless, the DP group also recognised that this is not often practised in the real world, as it is seen as an unnecessary risk and resource intensive (interviewees DP1, DP2, and DO1). This was also a general comment from the DP and DO group, where in an ideal situation it would be best to practise all areas of the design innovation spectrum, but it was felt there are many barriers to achieving this. They recognised, from their experiences, that there must be a strong need in a manufacturing firm’s senior management to adopt changes in design or even innovation, such as decreasing sales and market share of product(s), or increasing competition and diversification of the product range, etc. Even with these needs, some interviewees had difficulty convincing senior management to appreciate and use the expanding roles and capabilities of design (interviewees DP2, DP4, DO1, and DO2), and design is still firmly situated in the ‘designing’ area of the design innovation spectrum (interviewees MO1 and MO2).

The Design Innovation Spectrum in Practice

The practical implications of the design innovation spectrum were studied by using case studies of manufacturing companies, recognised for their innovativeness through various design and innovation awards. The manufacturing companies identified from these initial sources were then further investigated for company history, culture, processes, influences in the market, the philosophy of the top-level manager (CEO, managing directors, etc.), and success stories of design innovation (problem-solving) in order to understand and predict the use of areas of the design innovation spectrum. As the research used secondary sources for the case study, the descriptions and examples may not represent the activities, processes, or philosophy of the overall company. Some companies provided insights using multi-channels including interviews, blog-posts, promotional videos, etc., while others provided limited information on their activities and processes. However, the case study provides an overview of the practical implications of the design innovation spectrum for innovative manufacturing companies. The benefits of using ‘design’ in a manufacturing company are apparent from cases identified from the design-related awards. Similarly, the benefits of ‘innovation’ are clear from companies which have won manufacturing-oriented awards. Furthermore, by analysing the manufacturing companies, the research found elements of design innovation, even where the company does not use the specific term ‘design’ in their promotional materials and websites. The cases are thus categorised using the description of the areas of the design innovation spectrum: (i) ‘designing’ and ‘technological/product/service innovation’—the activities of a company which create artefacts or viable services to be launched in the market for a specific set of target customers, (ii) ‘design strategy’ and ‘process innovation’, which encompass strategic level decisions to manage and/or create design and innovation processes in order to increase efficiency, feasibility, and collaboration, and (iii) ‘corporate-level design thinking’ and ‘organisational innovation’ which include the creative management of an entire organisation and its business model through user-centred approaches, with clear vision from top-level management or fully supported by them both authoritatively and financially.

Manufacturing firms which used designing for technical, product, and service innovation development produced exemplary products that were regarded as innovative because of their financial success (dba Design Effectiveness Award and Queen’s Award for Enterprise) and by the experts in design and manufacturing (DME Award, EEF Award). Such companies demonstrated a common theme with their product ranges. The products variously (i) solve specific problems identified either by the users or by the company’s research (or the personal insights of the founders/directors), (ii) meet users’ requirements, (iii) have desirable qualities and/or aesthetics, and (iv) are timely in the market. The influences of design in producing these successful products and in new product development (NPD) were apparent with companies expressing the importance of ‘good design’ in their promotional literature, especially for consumer products. In comparison, industrial products emphasised ‘engineering’ or ‘functions’ more strongly, using the term ‘design’ specific for its technical ability to translate the idea into production, often as a synonym or as part of engineering. Furthermore, different perspectives (i.e., award types) provided evidence of the scope of design’s contribution to the products’ success. Design-oriented awards demonstrate design’s ability to understand the user and market demand, whereas the innovation award-winners tend to demonstrate a product’s functional and technical abilities, emphasising efficiency and cost-savings to their customers.

The strategy level of a business determines how a company utilises design professionals’ capabilities as a user/market representative, collaborative mediator, and holistic (system) thinker. The second category of companies demonstrated design as a catalyst to provide better processes in an NPD, using production and design to enhance process innovation. The cases provide insight of how design strategy increases process innovation by (i) collaborating with external organisations, (ii) streamlining the production and NPD process (lean manufacturing), e.g., by utilising automation and computer aided design (CAD), (iii) providing a holistic overview of the process from concept to point of sale, and (iv) allocating creative/collaborative space for employees. It is important to note, however, that design acts as an agent to achieve these tasks rather than merely as an advocate. Internal collaboration is therefore a key to improving process innovation through design strategy. The benefits of using design as a strategic tool is apparent both from the literatures and the case study, and is particularly evident with the design-oriented awards winners where business decisions to maximise the use of design in a company yielded rewards in increased production efficiency, sales and subsequent market share and profit, and by attracting new investment. These benefits improved the companies’ market competitiveness, exploitation of new markets (including overseas markets), and created an innovative culture with greater structured employee involvement. A ‘design champion’ or design manager is likely to operate at this level of business, taking on the role of an advocate of design values in the company. In order for a manufacturing company to become a design-led business, this area of the design innovation spectrum is critical because it is the area where balanced decision-making must occur between business-oriented decisions by top-level managements and the creative product/service decisions by the company’s design practitioners.

The research found that corporate-level design thinking can be used to improve organisational innovation, including the business model, company culture, company vision, and strategy by using the methods and philosophy of design which emphasise creativity and user-centred approaches. Furthermore, the extent of design involvement in the manufacturing companies in the case study relies heavily on the drive or support from top-level management. These commitments—demonstrated in the testimonials and success stories in winning the awards—may arguably be the biased top-level manager’s point of view. It is also difficult to determine whether design thinking is used to manage change in these companies. However, the manufacturing companies identified for this category clearly show that leaders place importance on understanding users and delivering the products required to meet their demands. Design thinking in management places the users at the heart of innovation, clearly demonstrating a major part of design thinking in practice. Furthermore, some companies demonstrated their ability to use business model changes to drive innovation. Entrepreneurial companies are also likely to implement changes for the company more enthusiastically as they discover new business possibilities while setting up the business. Continued innovation is important for the company to stay competitive in a rapidly changing market. Unfortunately some companies included in this study have subsequently been liquidated or show very limited activity. Whatever the reasons for this, it is a reminder that recognition as an innovative manufacturing company does not necessarily guarantee continued success without top-level managers’ commitment to adapt to the ever-changing market.

Use of the Design Innovation Spectrum

Most of the expert interviewees and the literatures indicate that the use of design in manufacturing companies is often limited to the ‘designing’ area of the design spectrum. Here innovation becomes a critical link in convincing the value of design because manufacturing companies regard innovation as important, and active conversations take place about wider areas of the innovation spectrum. Encouraging the use of design by providing information on the expanding spectrum of design and its effects on businesses in relation to innovation can thus provide a vital opportunity for companies to consider design when seeking to increase their innovation capabilities and subsequent global competitiveness. In order to better explain the full spectrum of design, the design innovation spectrum provides a map of design influences on improving various areas of innovation as also demonstrated in the case study. Furthermore, the expert interviews indicated three practical ways to increase acceptance of all areas of the Design Innovation Spectrum in the manufacturing context. Firstly, almost all the interviewees discussed the importance of a design champion or leader in a company. This role is not normally taken by designers, but by senior managers in manufacturing companies who are willing to take risks to use design more widely in various areas of a company, e.g., using corporate-level design thinking to improve the business model, and even the company vision and strategy. The second method the experts used to increase acceptance of design was building trust in design by succeeding and by exceeding expectations with smaller “activity level” projects (DP2, DP4, DP5, DO2, DO3, and MO3), and convincing senior management or the CEO that design can contribute more in the company’s strategic and organisational levels. Thirdly, the experts recognised that using successful case studies would be beneficial in attracting more interest for the whole Design Innovation Spectrum. This was often used by the DO group as an initial method to explain the use and benefits of design at different levels and in different situations in a business (DO1, DO2, and DO3).

The design innovation spectrum can also be used as a foundation when creating a design innovation audit tool once the full spectrum of design is recognised by the manufacturing companies, in order to identify possible improvement area(s) in which a company can act to increase their capabilities (Chiesa, Coughlan, & Voss, 1996). Some models and frameworks are already available to assess design capabilities, e.g., SEE project’s design ladder (Danish Design Centre, 2003), The Design Council’s Design Atlas (DC, 2007) and Matchbox (DC, 2010), and Moultrie et al.’s Design Audit for SMEs (Moultrie, Clarkson, & Probert, 2006). More established government-supported innovation audit tools include Nesta’s Total Innovation Index (Westlake et al., 2009), OECD/Eurostat’s (2005) Oslo Manual, and Keeley et al.’s (2013) Ten Types of Innovation. However, like many design and innovation researches, they measure the capabilities of either specific areas of the design spectrum or the innovation spectrum separately, missing the crucial opportunity to link all design capabilities in relation to various areas of innovation. Furthermore, the expert interviews revealed that only the DO group used The Design Council’s tools, and no other experts used any of the design audit tools listed above. The DP group used their own design assessment method: short conversations with ‘design champions’ or directors of the client companies, to help them understand the approach they should take to successfully manage a given project rather than systematically assessing the design capabilities. Only one interviewee (DP3) used an auditing method extensively to identify possible design improvement areas in organisations, perhaps because the manufacturing companies seldom see a need for a design audit, as design is regarded as an ‘add-on’ activity for a company (DP1 and MO1). Design audit is also regarded as a resource-intensive practice, lacking any clear benefit to a company (DO3). However, identifying the area of improvement requires an assessment of the current situation. The experts suggested how an audit might be more widely adopted by manufacturing companies. Therefore, when an audit tool is being developed using the design innovation spectrum as a basic structure, the following suggestions should be considered. Firstly, it must be usable: the assessment of design innovation capabilities by people and processes must be carefully designed and packaged in a way which is not burdensome to the company. Secondly, the audit tool must be also flexible to represent the need of each individual company environment (sector specific) and situation (design innovation maturity) in order to be useful for the company to successfully manage innovation (Hansen & Birkinshaw, 2007). The design innovation experts interviewed during the research agreed about this unanimously, and recommended that an implementation strategy must be clearly identified in areas of prioritisation tailored to individual companies.

Conclusion

This paper has identified the extensive influences of design—through designing, design strategy and corporate-level design thinking—in enhancing equally the extensive parameters of innovation including technological, products/services, process, and organisational innovation. Innovation is regarded as a key to re-establishing manufacturing strength in a rapidly changing global market, so rather than focusing primarily on traditional technology-led development, there is a strong push for manufacturing companies to utilise the expanding parameters of innovation more broadly in areas including process and organisational innovation at both the strategic and operational levels of business to increase competitiveness. This paper establishes the expanding parameters of design (the Design Spectrum) and innovation (the Innovation Spectrum), and the link between the two in the form of the Design Innovation Spectrum, to identify where and how design can be influential in cultivating innovation. The Design Innovation Spectrum builds on and combines existing frameworks which use design as a cognitive activity to solve pre-defined problems, e.g., in the area of ‘designing’ within NPD, and as a way of finding an appropriate route to identify opportunities among a complexity of ‘wicked’ problems, e.g., in the area of corporate-level design thinking to use creativity and empathy to construct a business model. The spectrum encompasses these design theories, identifying their relationship to innovation at different levels of business (activity, strategic, and organisational levels) to show the relevance of extensive areas of design in the business context.

For manufacturing companies which predominantly use ‘design’ as a science, this research suggests the additional value of design to manage business more creatively, in order to enhance organisational innovation (corporate-level design thinking) and, for companies which are competent in most areas of innovation, the Design Innovation Spectrum provides a design-led approach to further improve innovation and to increase competitiveness in a complex market. The design innovation spectrum can also be used as a map by profit or non-profit design support organisations when providing consultation to manufacturing companies to identify the areas of improvement appropriate to a company’s situation and environment. The research therefore also recommends using the Design Innovation Spectrum as a foundation to create a design innovation audit tool to increase innovativeness. Further research is recommended: (i) create the design innovation audit tool in a manufacturing company setting, (ii) investigate the strategic decision-making and implementation process after the audit to identify how design innovation can be improved in manufacturing companies, and (iii) extend the empirical research about the influence of design for innovation for companies in different industries, e.g., service and construction, etc., by conducting research with appropriate data sources specific to those industries.

Acknowledgments

The authors gratefully acknowledge the co-operation of all interview participants from design, innovation, and manufacturing areas in sharing their valuable knowledge and experiences.

References

- Altheide, D. L. (1987). Ethnographic content analysis. Qualitative Sciology, 10(1), 65-77.

- Banks, A., Hamroush, S., Taylor, C., & Hardie, M. (2014). An international perspective on the UK - Gross domestic product. London, UK: Office for National Statistics.

- Baregheh, A., Rowley, J., & Sambrook, S. (2009). Towards a multidisciplinary definition of innovation. Management Decision, 47(8), 1323-1339.

- Boston Consulting Group. (2014). The most innovative companies 2014: Breaking through is hard to do. Retrieved from https://www.bcgperspectives.com/most_innovative_companies

- Berkhout, A. J., Hartmann, D., Duin, P. V. D., & Ortt, R. (2006). Innovating the innovation process. International Journal of Technology Management, 34(3-4), 390-404.

- Bertola, P., & Teixeira, J. C. (2003). Design as a knowledge agent: How design as a knowledge process is embedded into organization to foster innovation. Design Studies, 24(2), 181-194.

- Best, K. (2006). Design management: Managing design strategy, process and implementation. Lausanne, Switzerland: AVA Publishing.

- Blaich, R. (1988). Design as a corporate strategy. In P. Gorb (Ed.), Design talks (pp. 9-26). London, UK: Design Council.

- Boothroyd, G., Dewhurst, P., & Knight, W. (2002). Product design for manufacture and assembly (2nd ed.). Boca Raton, FL: CRC Press.

- Brown, T. (2009). Change by design: How design thinking transforms organizations and inspires innovation. New York, NY: HarperCollins.

- Bruce, M., & Bessant, J. (2002). What is design? In M. Bruce & J. Bessant (Eds.), Design in business: Strategic innovation through design (pp. 18-33). Harlow, UK: Pearson Education.

- British Standards Institution. (2008). Design management systems - Part 10: Vocabulary of terms used in design management (BS 7000-10: 2008). Retrieved from https://shop.bsigroup.com/ProductDetail/?pid=000000000030163149

- Buchanan, R. (1992). Wicked problems in design thinking. Design Issues, 8(2), 5-21.

- Chiesa, V., Coughlan, P., & Voss, C. A. (1996). Development of a technical innovation audit. Journal of Product Innovation Management, 13(2), 105-136.

- Clark, K., & Smith, R. (2008). Unleashing the power of design thinking. Design Management Review, 19(3), 8-15.

- Cooper, R., & Junginger, S. (2009). The evolution of design management. Design Management Journal, 4(1), 4-6.

- Cooper, R., & Press, M. (1995). The design agenda: A guide to successful design management. Chichester, UK: John Wiley & Sons.

- Cox, G. (2005). Cox review of creativity in business: Building on the UK’s strengths. London, UK: HM Treasury.

- Cumming, B. S. (1998). Innovation overview and future challenges. European Journal of Innovation Management, 1(1), 21-29.

- Danish Design Centre. (2003). The economic effects of design. København, Denmark: Danish Design Centre.

- Department for Business, Innovation & Skills. (2010a). The economic rationale for a national design policy. Retrieved from https://www.gov.uk/government/publications/the-economic-benefits-of-a-national-design-policy

- Department for Business, Innovation & Skills. (2010b). Growth review framework for advanced manufacturing. Retrieved from https://www.gov.uk/government/publications/advanced-manufacturing-growth-review-framework

- Department for Business, Innovation & Skills. (2010c). Manufacturing in the UK: An economic analysis of the sector. Retrieved from https://www.gov.uk/government/publications/manufacturing-in-the-uk-economic-analysis

- Department for Business, Innovation & Skills. (2011). Innovation and research strategy for growth. Retrieved from https://www.gov.uk/government/publications/innovation-and-research-strategy-for-growth--2

- Department of Trade and Industry. (2003). Innovation report - Competing in the global economy: The innovation challenge. Retrieved from http://webarchive.nationalarchives.gov.uk/+/http:/www.dti.gov.uk/files/file12093.pdf

- Department of Trade and Industry. (2005). Creativity, design, and business performance. Retrieved from http://www.ico-d.org/database/files/library/economics_paper15.pdf

- Department of Trade and Industry. (2006). 60 minute guide to innovation–Turning ideas into profit. London, UK: TSO. Retrieved from http://www.knowlton.org.uk/wp-content/files/DTI%20iNNOVATION%20GUIDE.pdf

- Design Council. (2007). Eleven lessons: Managing design in eleven global companies. London, UK: Design Council.

- Design Council. (2008). The impact of design on business. London, UK: Design Council.

- Design Council. (2010). Designing demand: Make design deliver lasting success for your business. London, UK: Design Council.

- Design Council. (2014). Leading business by design: Why and how business leaders invest in design. London, UK: Warwick Business School and Design Council.

- Dumas, A., & Whitfield, A. (1989). Why design is difficult to manage: A survey of attitudes and practices in the British industry. European Management Journal, 7(1), 50-56.

- EEF. (2009). Manufacturing. Our future. London, UK: EEF.

- Fernández-Mesa, A., Alegre-Vidal, J., Chiva-Gómez, R., & Gutiérrez-Gracia, A. (2013). Design management capability and product innovation in SMEs. Management Decision, 51(3), 547-565.

- Fraser, H. M. A. (2009). Designing business: New models for success. Design Management Review, 20(2), 56-65.

- Freel, M. S. (2000). Strategy and structure in innovative manufacturing SMEs: The case of an English region. Small Business Economics, 15(1), 27-45.

- Gemser, G. (1997). Industrial design for competitiveness. Paper presented at the European Academy of Design Conference on Contextual Design/Design in Context, 23-25 April, Stockholm, Sweden.

- Gemser, G., Candi, M., & Ende, J. V. D. (2011). How design can improve firm performance. Design Management Review, 22(2), 72-77.

- Gorb, P. (1986). The business of design management. Design Studies, 7(2), 106-110.

- Hansen, M. T., & Birkinshaw, J. (2007). The innovation value chain. Harvard Business Review, 85(6), 121-130.

- Harris, M., & Cox, J. (2008). Total innovation: Why harnessing the hidden innovation in high-technology sector is crucial to retaining the UK’s innovative edge. London, UK: Nesta.

- Hatchuel, A., & Weil, B. (2003). A new approach of innovative design: An introduction to C-K theory. In Proceedings of the 41th International Conference of Engineering Design (no. DS31_1794FPC). Retrieved from https://www.designsociety.org/publication/24204/a_new_approach_of_innovative_design_an_introduction_to_c-k_theory

- Jolly, A. (Ed.). (2010). The innovation handbook (2nd ed.). London, UK: Kogan Page.

- Keeley, L., Pikkel, R., Quinn, B., & Walters, H. (2013). Ten types of innovation: The discipline of building breakthroughs. Hoboken, NJ: John Wiley & Sons.

- Laforet, S., & Tann, J. (2006). Innovative characteristics of small manufacturing firms. Journal of Small Business and Enterprise Development, 13(3), 363-380.

- Le Masson, P., Benoit, W., & Hatchuel, A. (2010). Strategic management of innovation and design. Cambridge, UK: Cambridge University Press.

- Liedtka, J., & Ogilvie, T. (2011). Designing for growth: A design thinking tool kit for managers. New York, NY: Columbia Business School Publishing.

- Lindbeck, J. R. (1995). Product design and manufacture. Englewood Cliffs, NJ: Prentice Hall.

- Livesey, F., & Moultrie, J. (2009). Company spending on design: Exploratory survey of UK firms 2008. London, UK: Univerisity of Cambridge and Design Council.

- Love, J. H., Roper, S., & Du, J. (2009). Innovation, ownership, and profitability. International Journal of Industrial Organization, 27(3), 424-434.

- Martin, R. (2009). The design of business: Why design thinking is the next competitive advantage. Boston, MA: Harvard Business Press.

- Manyika, J., Sinclair, J., Dobbs, R., Strube, G., Rassey, L., Mischke, J., …, & Ramaswamy, S. (2012). Manufacturing the future: The next era of global growth and innovation. New York, NY: McKinsey Global Institute. Retrieved from http://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing

- Mootee, I. (2013). Design thinking for strategic innovation: What they can’t teach you at business or design school. Hoboken, NJ: John Wiley & Sons.

- Mosey, S., Clare, J. N., & Woodcock, D. J. (2002). Innovation decision making in British manufacturing SMEs. Integrated Manufacturing Systems, 13(3), 176-184.

- Moultrie, J., Clarkson, P. J., & Probert, D. (2006). A tool to evaluate design performance in SMEs. International Journal of Productivity and Performance Management, 55(3/4), 184-216.

- Mozota, B. B. D.(1990). Design as a strategic management tool. In M. Oakley (Ed.), Design management: A handbook of issues and methods (pp. 73-84). Oxford, UK: Blackwell.

- Mozota, B. B. D. (2003). Design management: Using design to build brand value and corporate innovation. New York, NY: Allworth Press.

- Na, J., & Choi, Y. (2012). The future of UK manufacturing: The development of corporate-level design policy for UK innovative manufacturing. Paper presented at the International Research Conference on Leading Innovation through Design, 8-9 August, Boston, MA.

- Needle, D. (2010). Business in context: An introduction to business and its environment (5th ed.). Hampshire, UK: Cengage Learning EMEA.

- Neumeier, M. (2008). The designful company. Design Management Review, 19(2), 10-15.

- Nussbaum, B. (2007). CEOs must be designers, not just hire them. Think Steve Jobs and iPhone. Nussbaum on Design. Retrieved from http://www.businessweek.com/innovate/NussbaumOnDesign/archives/2007/06/ceos_must_be_designers_not_just_hire_them_think_steve_jobs_and_iphone.html

- OECD/Eurostat. (2005). Oslo manual: Guidelines for collecting and interpreting innovation data (3rd ed.). Paris, France: OECD Publishing. http://dx.doi.org/10.1787/9789264013100-en

- Patton, M. Q. (2001). Qualitative evaluation and research methods. Thousand Oaks, CA: Sage.

- Poli, C. (2001). Design for manufacturing: A structured approach. Woburn, MA: Butterworth-Heinemann.

- Press, M., & Cooper, R. (2003). The design experience: The role of design and designers in the twenty-first century. Hants, UK: Ashgate Publishing.

- Prest, M. (2008). The return of manufacturing in Britain. London, UK: Prospect.

- PricewaterhouseCoopers. (2009). The future of UK manufacturing: Reports of its death are greatly exaggerated. Retrieved from https://www.pwc.co.uk/assets/pdf/ukmanufacturing-300309.pdf

- PricewaterhouseCoopers. (2013a). Breakthrough innovation and growth: Top innovators expect US$250 billion five-year revenue boost. Retrieved from https://www.pwc.com/ca/en/consulting/publications/pwc-breakthrough-innovation-growth-canada-2013-11-en.pdf

- PricewaterhouseCoopers. (2013b). Dealing with disruption: Adapting to survive and thrive. Retrieved from http://www.pwc.com.tr/tr/publications/arastirmalar/pdf/pwc-16th-annual-global-ceo-survey.pdf

- PricewaterhouseCoopers. (2014). Fit for the future: Capitalising on global trends. Retrieved from https://www.pwc.com/gx/en/ceo-survey/2014/assets/pwc-17th-annual-global-ceo-survey-jan-2014.pdf

- Pugh, S. (1996). Creating innovative products using total design. Upper Saddle River, NJ: Prentice Hall.

- Roper, S., Hales, C., Bryson, J. R., & Love, J. (2009). Measuring sectoral innovation capability in nine areas of the UK economy. Retrieved from http://www.nesta.org.uk/publications/measuring-sectoral-innovation-capability-nine-areas-uk-economy

- Rothwell, R. (1994). Towards the fifth-generation innovation process. International Marketing Review, 11(1), 7-31.

- Simon, H. A. (1996). The sciences of the artificial (3rd ed.). Cambridge, MA: MIT Press.

- Swann, P., & Birke, D. (2005). How do creativity and design enhance business performance?: A framework for interpreting the evidence. Nottingham, UK: Nottingham University Business School.

- Technology Strategy Board. (2012a). High value manufacturing strategy 2012 to 2015. Retrieved from https://www.gov.uk/government/publications/high-value-manufacturing-strategy-2012-to-2015

- Technology Strategy Board. (2012b). A landscape for the future of high value manufacturing in the UK. Retrieved from http://www.ifm.eng.cam.ac.uk/insights/national-innovation-policies/ukhvmlandscape/

- Temple, M. (2011). Sir Martin Temple introduces the second session of design summit 11. Retrieved from http://www.designcouncil.org.uk/our-work/Insight/Design-for-Growth/summit11webcast/Sir-Martin-Temple/

- Tether, B. (2005). Think piece on the role of design in business performance. London, UK: Department of Trade and Industry.

- Tether, B. (2009). Design in innovation: Coming out from the shadow of R&D. London, UK: Department for Innovation, Universities and Skills.

- Trueman, M., & Jobber, D. (1998). Competing through design. Long Range Planning, 31(4), 594-605.

- Tucker, R. B. (2001). Innovation: The new core competency. Strategy & Leadership, 29(1), 11-14.

- Utterback, J. (1986). Innovation and corporate strategy. International Journal of Technology Management, 1(1-2), 119-132.

- Verganti, R. (2009). Design-driven innovation: Changing the rules of competition by radically innovating what things mean. Boston, MA: Harvard Business Press.

- Visser, W. (2009). Design: One, but in different forms. Design Studies, 30(3), 187-223.

- West, M., & Anderson, N. R. (1996). Innovation in top management teams. Journal of Applied Psychology, 81(6), 680-693.

- Westlake, S., MacAulay, B., Gratzke, P., Bravo-Biosca, A., & Bakhshi, H. (2009). The innovation index: Measuring the UK’s investment in innovation and its effects. London, UK: Nesta.